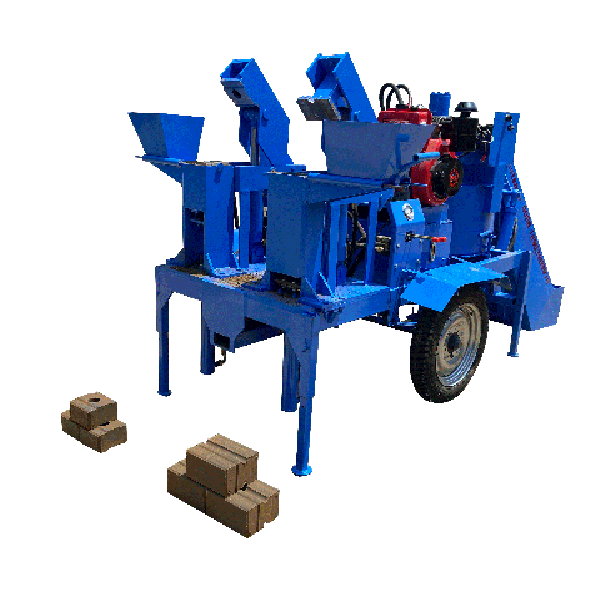

The M7MI TWIN diesel hydraform soil brick machine is designed with efficiency in mind, requiring only three workers to operate effectively. Two workers serve as machine operators, while one worker is responsible for supplying raw materials to the pan mixer and hopper. This streamlined labor requirement makes the M7MI TWIN diesel hydraform brick machine an ideal choice for projects looking to maximize productivity while minimizing operational costs. Its user-friendly design ensures that even a small team can produce high-quality soil bricks efficiently. In this article, we’ll explore the labor requirements, operational benefits, and key features of the M7MI TWIN diesel hydraform soil brick machine.

The Role of Workers in Operating the M7MI TWIN Diesel Hydraform Soil Brick Machine

Understanding the Labor Requirements

The M7MI TWIN diesel hydraform soil brick machine is engineered with simplicity and efficiency in mind. As mentioned earlier, it only takes three workers to run this machine effectively. Let’s break down their roles:

– Two Machine Operators: These workers operate the controls and oversee the brick production process, ensuring the machine runs smoothly.

– One Material Handler: This worker is responsible for supplying raw materials (such as soil and stabilizers) to the pan mixer and the working platform hopper.

This minimal workforce requirement is a key advantage of the machine, as it reduces labor costs while ensuring high output. Unlike traditional brick-making methods that demand larger teams, this diesel hydraform brick machine offers an efficient, cost-effective solution for construction projects.

Why Minimal Labor Matters?

Requiring fewer workers isn’t just about saving money – it’s also about simplifying operations. With fewer staff members, there’s less room for error, and training becomes easier. The M7MI TWIN diesel engine brick machine’s user-friendly design ensures that even workers with minimal technical experience can operate it effectively. This makes it an excellent choice for both large-scale construction projects and smaller operations in remote areas.

Key Features That Simplify Operation

Diesel Engine Power for Remote Locations

One of the standout features of the M7MI TWIN diesel hydraform soil brick machine is its diesel engine, which eliminates the need for an external power source. This makes it ideal for rural or off-grid locations where electricity may not be readily available. The diesel engine ensures consistent performance, even in challenging environments.

Additionally, the diesel engine is designed for fuel efficiency, reducing operational costs further. This feature, combined with the machine’s minimal labor requirement, makes it a highly cost-effective choice for brick production.

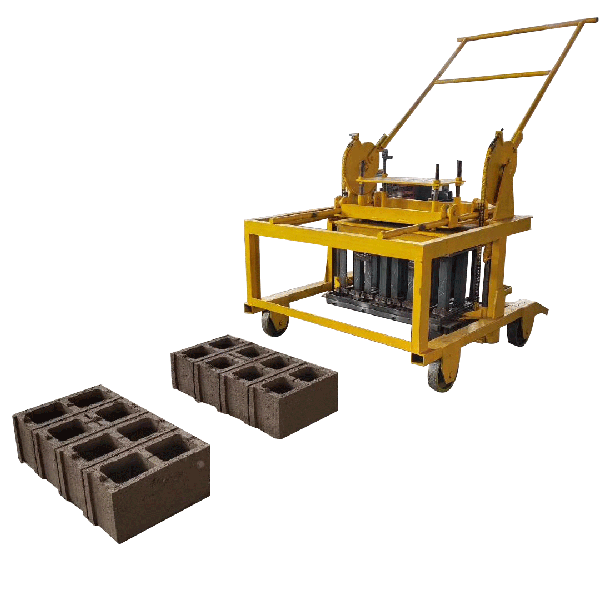

Mobility and Compact Design

The mobile block-making machinery design of the M7MI TWIN allows it to be easily transported to different construction sites. Its compact structure ensures it can operate efficiently in confined spaces, making it suitable for both urban and rural projects. The mobility of this machine also eliminates the need to transport bricks over long distances, further reducing costs and saving time.

This mobility feature is particularly beneficial for contractors working on multiple sites, as the machine can be quickly relocated and set up with minimal downtime.

High-Quality Production with Minimal Supervision

The diesel engine brick machine‘s advanced engineering ensures consistent, high-quality brick production. The dual production system of the M7MI TWIN allows it to produce two bricks simultaneously, doubling productivity compared to single-brick machines.

– Bricks are compressed with high pressure, resulting in durable and uniform products suitable for a wide range of construction applications.

– The automatic mixing and compression processes reduce the need for constant supervision, allowing operators to focus on other tasks.

These features not only enhance productivity but also ensure that the machine remains easy to operate, even for smaller teams.

Benefits of the M7MI TWIN Diesel Hydraform Soil Brick Machine for Your Project

Cost-Effectiveness

The combination of low labor requirements, fuel-efficient diesel engine, and high brick output makes this machine a cost-effective solution for construction projects. By reducing the need for large teams and cutting down on energy expenses, the M7MI TWIN diesel hydraform brick machine helps businesses save money without compromising on quality.

Versatility in Brick Production

This machine is capable of producing a wide range of soil bricks, making it suitable for various construction needs. Whether you’re building homes, schools, or commercial buildings, the M7MI TWIN can adapt to your project’s requirements. Its ability to use locally available materials, such as soil and stabilizers, further enhances its versatility and cost efficiency.

Environmentally Friendly Design

The M7MI TWIN diesel engine brick machine is designed to minimize environmental impact. By using soil as the primary raw material and reducing the need for transportation, the machine helps lower the carbon footprint of construction projects. Additionally, its fuel-efficient diesel engine ensures that energy consumption is kept to a minimum.

Durability and Reliability

Constructed with high-quality materials, the M7MI TWIN diesel hydraform soil brick machine is built to withstand tough working conditions. Its robust design ensures long-term reliability, reducing the need for frequent repairs and maintenance. This durability makes it a smart investment for businesses looking for a machine that will deliver consistent performance for years to come.

Conclusion

The M7MI TWIN diesel hydraform soil brick machine offers the perfect combination of efficiency, cost-effectiveness, and versatility. With a small team of just three workers, you can produce high-quality soil bricks quickly and reliably. Its diesel engine power, mobile design, and low labor requirements make it an excellent investment for construction businesses aiming to streamline operations and reduce costs.

Contact Us

If you’re looking for a durable, efficient, and environmentally friendly brick-making solution, the M7MI TWIN diesel hydraform soil brick machine is the answer. Contact us today at hazel@raytonechina.com to learn more about how this machine can transform your construction projects.

References

- Hydraform Soil Brick Machine Operation Manuals

- Diesel Engine Efficiency in Construction Machinery

- Mobile Block-Making Machinery: Benefits and Applications

- Cost-Effective Construction Solutions with Hydraform Machines

- The Role of Compressed Soil Bricks in Sustainable Construction

- Productivity and Labor Efficiency in Brick-Making Operations