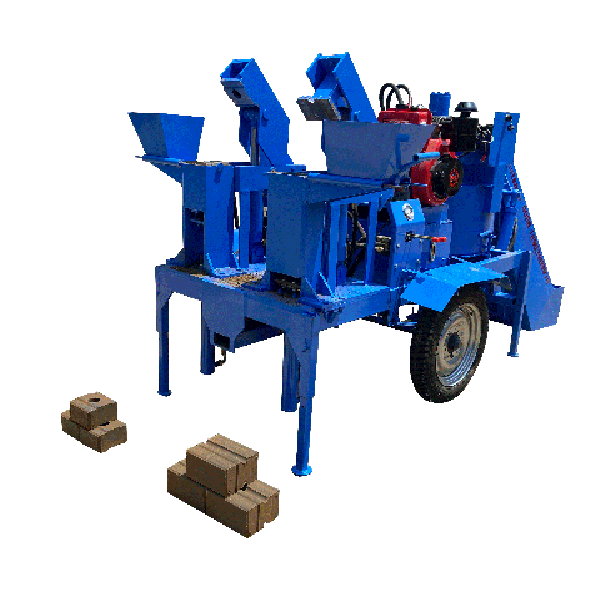

The M7MI TWIN diesel hydraform soil brick machine is a versatile and eco-friendly solution for brick-making, primarily using locally available soil, clay, or earth as raw materials. This machine allows for the creation of high-density interlocking bricks by mixing soil with small amounts of cement and water. Its customizable raw material formulas make it adaptable to various soil conditions, ensuring cost-effective solutions for a wide range of environments. Whether you’re working with clay-rich soil or a mix of local earth, the M7MI TWIN diesel hydraform soil brick machine offers the flexibility to produce durable bricks with minimal resources.

Understanding the Raw Material Composition for the M7MI TWIN Diesel Hydraform Soil Brick Machine

To produce high-quality interlocking bricks, the M7MI TWIN Diesel Hydraform Soil Brick Machine requires a combination of raw materials that are cost-efficient, locally sourced, and environmentally sustainable. The machine’s design allows for two specific formulas, each tailored to the characteristics of the soil available in different regions.

Optimal Clay Usage for Brick Production

Clay is the primary raw material for the M7MI TWIN Diesel Hydraform Soil Brick Machine. Its natural binding properties make it ideal for brick-making. Depending on local soil conditions, the machine can handle formulas with either 80-90% clay or as high as 97% clay. The flexibility in clay proportions ensures adaptability, allowing users to maximize the potential of available resources.

The diesel hydraform brick machine‘s ability to process high clay content reduces the need for additional materials, making it a cost-effective choice for remote areas where resources may be limited. The result is bricks with excellent compressive strength and density, ensuring long-lasting construction projects.

The Role of Cement in Enhancing Brick Strength

Cement plays a crucial role as a stabilizing agent in the raw material mix. In the formula containing 80-90% clay, 6-8% cement is added to improve the durability and water resistance of the bricks. This addition ensures that the finished bricks can withstand harsh weather conditions and heavy loads, making them suitable for a variety of construction applications.

For areas with limited access to cement, the M7MI TWIN Diesel Hydraform Soil Brick Machine can function with minimal cement or none at all. The alternative formula of 97% clay and 3% water relies on the natural properties of the clay to create strong interlocking bricks, further reducing production costs.

Water: A Key Ingredient for Binding

Water is the final critical component in the brick-making process. It acts as a binding agent, ensuring the clay and cement mix evenly and compact effectively. The machine requires as little as 3% water, making it ideal for regions where water is scarce. The low water requirement enhances the machine’s environmental sustainability by minimizing resource consumption.

By carefully balancing these three materials – clay, cement, and water – the M7MI TWIN Diesel Hydraform Soil Brick Machine ensures high-quality brick production that is both efficient and eco-friendly.

Why Customizable Formulas Are Essential for Different Environments?

One of the standout features of the M7MI TWIN Diesel Hydraform Soil Brick Machine is its ability to adapt to various soil and environmental conditions. This adaptability allows users to produce bricks that meet specific structural and environmental needs.

Adapting to Local Soil Conditions

The availability and composition of soil vary significantly from one location to another. In some regions, soil may have a high clay content, while in others, it may be sandy or mixed with organic matter. The adjustable raw material formulas of the M7MI TWIN diesel hydraform soil brick machine ensure that users can work with whatever soil is available locally, minimizing the need for expensive imported materials.

For example:

– In areas with clay-rich soil, the 97% clay, 3% water formula is ideal.

– In regions with less cohesive soil, adding 6-8% cement can improve brick quality and stability.

This flexibility not only reduces production costs but also ensures that the bricks produced meet the specific demands of local construction projects.

Cost-Effective Brick Production

By utilizing locally available materials, the M7MI TWIN Diesel Hydraform Soil Brick Machine significantly reduces production costs. The minimal use of cement and water further lowers expenses, making it an economical choice for small and large-scale projects alike. Additionally, the reduced reliance on external resources makes the machine an excellent option for remote or underdeveloped regions.

Environmental Sustainability

The use of natural soil and minimal water in brick-making contributes to the eco-friendliness of the M7MI TWIN mobile block making machinery. By reducing the need for energy-intensive materials like cement, the machine helps lower the carbon footprint of construction projects. This sustainability is particularly beneficial in regions aiming to promote green building practices and reduce environmental impact.

Advantages of the M7MI TWIN Diesel Hydraform Soil Brick Machine in Brick-Making

The M7MI TWIN Diesel Hydraform Soil Brick Machine is more than just a brick-making machine – it’s a transformative tool for sustainable construction. Its ability to produce high-quality bricks from simple raw materials makes it a valuable asset for builders, contractors, and community development projects.

High-Quality Interlocking Bricks

The machine’s advanced compression technology ensures that each brick is compact, dense, and durable. These interlocking bricks require less mortar during construction, speeding up the building process and reducing costs. The bricks’ design also enhances structural stability, making them suitable for homes, schools, and other infrastructure projects.

Mobile and Diesel-Powered

As a diesel engine brick machine, the M7MI TWIN is ideal for areas with limited or no access to electricity. Its mobility allows it to be transported easily to different construction sites, making it a versatile option for rural and remote regions. The diesel engine provides reliable power, ensuring consistent brick production even in challenging environments.

Ease of Operation

The M7MI TWIN Diesel Hydraform Soil Brick Machine is designed with user-friendliness in mind. Its simple operating system allows even unskilled workers to produce high-quality bricks efficiently. This ease of use makes it an excellent choice for community-driven projects and small-scale builders looking to maximize productivity.

Cost Savings and Efficiency

By using locally available materials and requiring minimal cement and water, the M7MI TWIN Diesel Hydraform Soil Brick Machine reduces production costs significantly. Its high output capacity ensures that large quantities of bricks can be produced quickly, making it a cost-effective solution for both small and large-scale construction projects.

Conclusion

The M7MI TWIN diesel hydraform soil brick machine is a game-changer in the world of brick-making, offering a sustainable, cost-effective, and versatile solution for construction projects worldwide. By leveraging local materials like clay, cement, and water, this diesel-powered machine produces high-density interlocking bricks that are durable, eco-friendly, and affordable. Its customizable formulas, adaptability to various environments, and ease of operation make it an invaluable tool for builders and developers looking to balance quality with cost-efficiency.

Contact Us

Raytone Machinery is proud to offer the M7MI TWIN Diesel Hydraform Soil Brick Machine and other high-quality block-making solutions. With our commitment to innovation, reliability, and customer satisfaction, we help you achieve your construction goals efficiently and affordably. To learn more about our products and how they can benefit your business, contact us today at hazel@raytonechina.com. Start building smarter with Raytone Machinery!

References

- Overview of soil-based construction materials and their sustainability benefits.

- Properties of clay as a raw material for brick production.

- The role of cement in improving brick quality and durability.

- Environmental benefits of interlocking brick systems.

- Diesel engine technology in mobile brick-making machines.

- Case studies on cost-effective construction using hydraform brick machines.