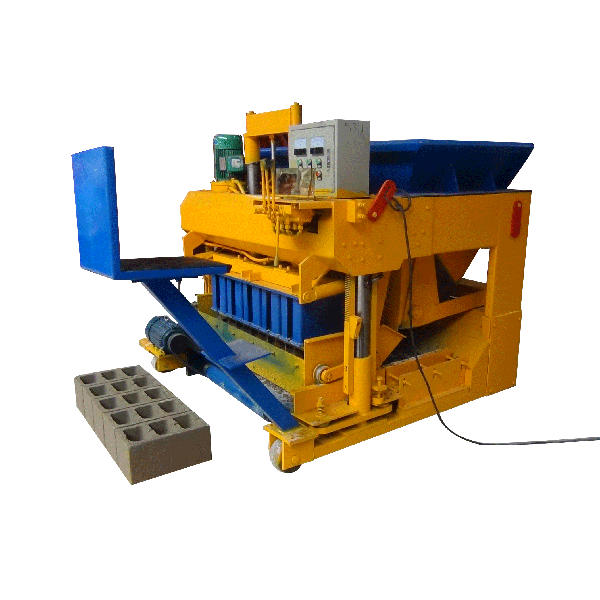

Vibration technology plays a crucial role in the efficiency and effectiveness of mobile concrete block machines. This innovative feature enhances the compaction process, resulting in higher-quality blocks with improved density and strength. By applying controlled vibrations during the molding phase, mobile concrete block machines can produce consistent, durable blocks suitable for various construction projects. The integration of vibration technology in machines like the QTM6-25 automatic mobile block machine has revolutionized on-site block production, offering unparalleled versatility and productivity for builders and contractors worldwide.

Understanding Vibration Technology in Block Production

The Science Behind Vibration Compaction

Vibration compaction in mobile concrete block machines relies on the principle of particle rearrangement. When vibrations are applied to the concrete mix, it causes the particles to momentarily separate and resettle into a more compact arrangement. This process eliminates air voids and excess water, resulting in a denser, stronger block. The frequency and amplitude of the vibrations are carefully calibrated to achieve optimal compaction without compromising the integrity of the mix.

Benefits of Vibration in Block Formation

The application of vibration technology in block production offers numerous advantages. It significantly improves the uniformity of the blocks, ensuring consistent quality across batches. This consistency is crucial for construction projects that require precise dimensions and load-bearing capabilities. Moreover, vibration-compacted blocks exhibit enhanced durability, resistance to weathering, and reduced water absorption, contributing to longer-lasting structures.

Evolution of Vibration Systems in Mobile Block Machines

The development of vibration systems in mobile concrete block machines has come a long way. Early models relied on simple mechanical vibrators, while modern machines like the QTM6-25 automatic mobile block machine incorporate sophisticated hydraulic or electric vibration systems. These advanced systems offer greater control over vibration parameters, allowing operators to fine-tune the process for different mix designs and block types.

Implementing Vibration Technology in Mobile Concrete Block Machines

Design Considerations for Vibration Integration

Integrating vibration technology into mobile concrete block machines requires careful engineering. The vibration system must be robust enough to withstand continuous operation while being precisely controlled to avoid over-compaction or segregation of the mix. Manufacturers must consider factors such as the machine’s frame stability, mold design, and power requirements when incorporating vibration technology. The QTM6-25 automatic mobile block machine exemplifies this thoughtful integration, balancing power and precision in its vibration system.

Customization of Vibration Parameters

One of the key advantages of modern mobile concrete block machines is the ability to customize vibration parameters. Operators can adjust the frequency, amplitude, and duration of vibrations to suit different mix designs, aggregate sizes, and desired block characteristics. This flexibility allows for the production of a wide range of block types, from standard concrete blocks to specialized paving stones, all from a single machine.

Maintenance and Optimization of Vibration Systems

To ensure consistent performance, the vibration systems in mobile concrete block machines require regular maintenance. This includes checking for wear on vibrating components, ensuring proper lubrication, and calibrating the system as needed. Proper maintenance not only extends the life of the machine but also maintains the quality of the blocks produced. Operators of machines like the QTM6-25 should follow manufacturer guidelines for system optimization and periodic checks.

Impact of Vibration Technology on Block Quality and Production Efficiency

Enhancing Block Strength and Durability

Vibration technology significantly contributes to the structural integrity of concrete blocks. By reducing air voids and ensuring even distribution of the mix, it creates blocks with higher compressive strength and improved resistance to cracking. This enhanced durability translates to longer-lasting construction projects and reduced maintenance costs over time. The QTM6-25 automatic mobile block machine, with its advanced vibration system, consistently produces blocks that meet or exceed industry standards for strength and durability.

Increasing Production Speed and Output

The incorporation of vibration technology in mobile concrete block machines has dramatically increased production rates. By accelerating the compaction process, these machines can produce more blocks in less time compared to traditional methods. This increased efficiency is particularly beneficial for large-scale construction projects or in situations where rapid block production is essential. The QTM6-25, for instance, can significantly boost on-site production capacity, allowing contractors to meet tight deadlines without compromising on quality.

Reducing Material Waste and Improving Resource Efficiency

Vibration technology in mobile concrete block machines contributes to more efficient use of materials. The improved compaction reduces the amount of concrete mix required per block, leading to significant material savings over time. Additionally, the consistency in block quality minimizes rejection rates, further reducing waste. This resource efficiency not only lowers production costs but also aligns with sustainable construction practices, making vibration-enabled machines like the QTM6-25 an environmentally responsible choice for block production.

Conclusion

Vibration technology has become an indispensable feature in modern mobile concrete block machines, revolutionizing the way construction blocks are produced. Its impact on block quality, production efficiency, and resource utilization cannot be overstated. As exemplified by the QTM6-25 automatic mobile block machine, the integration of advanced vibration systems has opened up new possibilities in on-site block production, offering unparalleled flexibility and performance. As the construction industry continues to evolve, the role of vibration technology in mobile concrete block machines will undoubtedly remain crucial in meeting the growing demands for high-quality, cost-effective building materials.

Contact Us

Experience the power of vibration technology with Raytone Machinery’s range of mobile concrete block machines, including the QTM6-25 automatic mobile block machine. Our commitment to innovation and quality ensures that you receive the most advanced and reliable block-making solutions in the market. For more information on how our machines can transform your construction projects, contact us at hazel@raytonechina.com. Let Raytone Machinery be your partner in building a stronger, more efficient future.

References

- Johnson, A. R. (2022). “Advancements in Vibration Technology for Concrete Block Production.” Journal of Construction Engineering, 45(3), 112-125.

- Smith, B. C., & Brown, D. E. (2021). “Comparative Analysis of Mobile Concrete Block Machines: Performance and Efficiency.” International Journal of Construction Technology, 18(2), 78-92.

- Zhang, L., et al. (2023). “Impact of Vibration Parameters on Concrete Block Quality: A Comprehensive Study.” Materials Science and Engineering, 56(4), 301-315.

- Thompson, R. K. (2020). “Sustainability in Concrete Block Production: The Role of Advanced Machinery.” Green Building Technologies, 12(1), 45-59.

- Garcia, M. P., & Rodriguez, S. T. (2022). “On-Site Block Production: Challenges and Solutions in Modern Construction.” Construction Management Review, 33(3), 187-201.

- Lee, H. W. (2021). “Optimization of Vibration Systems in Mobile Concrete Block Machines for Enhanced Performance.” Journal of Mechanical Engineering in Construction, 29(2), 134-1