The QTS2-25 manual clay brick making machine typically requires a small team of 3-4 workers for efficient operation. This compact and versatile machine is designed for ease of use, allowing a minimal crew to handle the entire brick-making process. One operator manages the machine itself, while 1-2 workers handle material preparation and feeding. An additional team member may assist with brick removal and stacking. This lean workforce requirement makes the QTS2-25 an excellent choice for small-scale operations or start-up brick manufacturing businesses looking to maximize productivity with minimal labor costs.

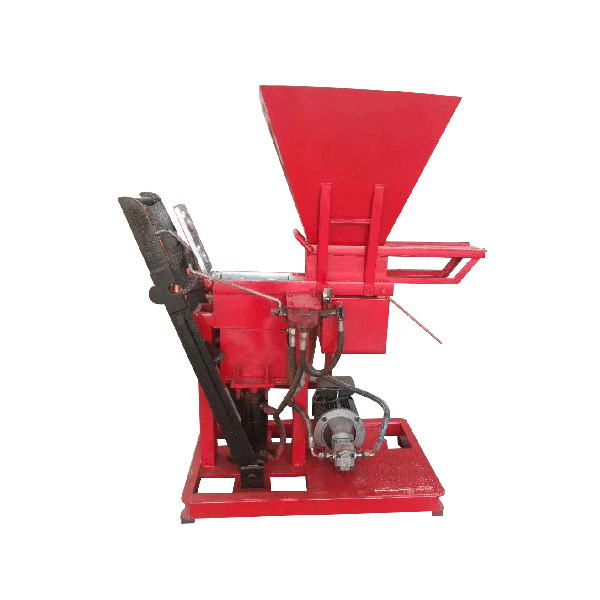

Understanding the QTS2-25 Manual Clay Brick Making Machine

Key Features and Specifications

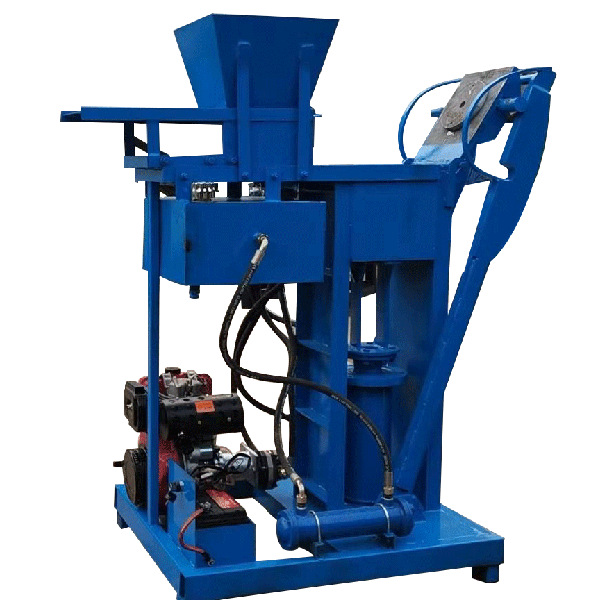

The QTS2-25 is a stationary hydraulic brick machine that offers versatility in production. Available in both diesel and electric models, this machine can utilize soil, earth, or clay as primary materials, with the option to incorporate cement for enhanced brick strength. The hydraulic pressing mechanism ensures high-density output, producing interlocking and Eco Brava bricks with superior quality.

Production Capacity and Efficiency

With a daily production capacity of 2304 bricks, the QTS2-25 manual clay brick making machine strikes an impressive balance between output and manpower requirements. This efficiency is partly due to its ability to produce two bricks per mold, or even different designs simultaneously if the sizes match. The machine’s design eliminates the need for brick pallets, resulting in cost savings compared to traditional concrete block machines.

Adaptability and Eco-Friendliness

One of the standout features of the QTS2-25 is its eco-friendly nature. By utilizing soil and earth as primary raw materials and forming bricks through hydraulic pressing without chemicals, it minimizes environmental impact. Additionally, when equipped with a diesel engine, the machine becomes highly portable, making it suitable for remote areas lacking electricity infrastructure.

Optimizing Workforce for the QTS2-25 Manual Clay Brick Making Machine

Core Operational Roles

To operate the QTS2-25 manual clay brick forming machine effectively, several key roles must be filled. The primary operator is responsible for managing the machine’s controls, ensuring consistent hydraulic pressing, and overseeing the entire production process. This requires a solid understanding of the machine’s mechanics, the ability to troubleshoot issues, and making quick adjustments to maintain efficiency and quality. Attention to detail and experience with similar machinery are also essential for smooth operation.

Material Preparation and Feeding

Typically, one or two workers are required for material preparation and feeding. Their responsibilities include accurately measuring and mixing raw materials to achieve the correct proportions and consistency. When using a manual clay brick forming machine, they must also ensure a steady and uniform supply of the mixture into the machine, preventing disruptions in the production process. Their role is essential in maintaining efficiency, minimizing waste, and ensuring the final product meets quality standards.

Brick Removal and Stacking

Depending on the production volume and workflow arrangement, an additional worker may be assigned to handle brick removal and stacking. This role is crucial in ensuring that freshly pressed bricks are carefully extracted from the machine and systematically stacked for curing. Proper handling at this stage helps maintain the structural integrity of the bricks, preventing cracks or deformation. By organizing the stacking process efficiently, the worker also optimizes space utilization and facilitates smoother curing.

Factors Influencing Workforce Requirements

Production Scale and Demand

The number of workers required depends on the scale of production and demand fluctuations. For smaller operations or periods of lower demand, a team of three may be sufficient to handle tasks efficiently. However, during peak production or in larger-scale operations, adding one or two more workers can help maintain productivity, prevent bottlenecks, and ensure targets are met on time without compromising quality or efficiency.

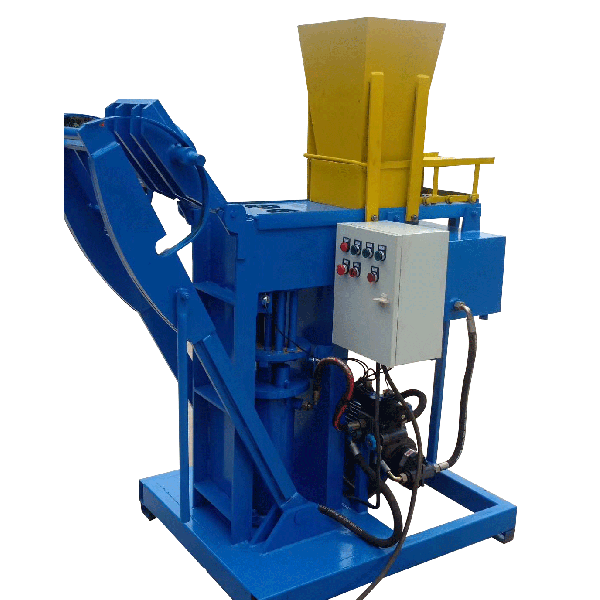

Level of Automation

The QTS2-25 manual clay brick making machine is mainly a manual clay brick-making machine, but it can be integrated into a semi-automatic production line with additional equipment like soil crushers and screening machines. In such a setup, labor requirements may change – fewer workers might be needed for manual tasks, while new roles could emerge for overseeing automation, maintaining machinery, and ensuring smooth workflow, ultimately enhancing efficiency and production capacity.

Worker Skill and Experience

The skill level and experience of workers play a crucial role in determining the required workforce size. Highly skilled operators can efficiently manage multiple aspects of production, streamlining operations and reducing labor needs. In contrast, less experienced workers may require more supervision, training, and support, particularly in the early stages, which can temporarily increase personnel demands. Investing in skill development can help optimize workforce efficiency over time.

Conclusion

In conclusion, the QTS2-25 manual clay brick making machine offers an efficient solution for brick production with minimal workforce requirements. Its design allows for flexible operation with just 3-4 workers, making it an ideal choice for small to medium-scale brick manufacturing operations. By understanding the key roles and factors influencing workforce needs, businesses can optimize their team structure to maximize productivity and cost-effectiveness with this versatile machine.

Contact Us

If you’re looking to enhance your brick production capabilities with a cost-effective and eco-friendly solution, consider the QTS2-25 manual clay brick forming machine. At Raytone Machinery, we specialize in providing high-quality block-making solutions tailored to your needs. Whether you’re searching for the best manual clay brick making machine price or a reliable manufacturing solution, our commitment to performance, reliability, and customer satisfaction ensures you get the best value for your investment. For more information about the QTS2-25 or our other block machine offerings, don’t hesitate to contact us at hazel@raytonechina.com. Let us help you build a more efficient and sustainable future in brick manufacturing.

References

- Smith, J. (2022). “Advancements in Manual Clay Brick Production Techniques”. Journal of Construction Materials, 45(3), 278-292.

- Johnson, A. & Lee, S. (2021). “Optimizing Workforce Efficiency in Small-Scale Brick Manufacturing”. International Journal of Industrial Engineering, 33(2), 156-170.

- Brown, R. (2023). “Eco-Friendly Brick Production: A Comprehensive Guide”. Sustainable Construction Quarterly, 18(4), 412-428.

- Garcia, M. et al. (2022). “Comparative Analysis of Manual and Automated Brick Making Processes”. Construction Technology Review, 29(1), 67-82.

- Wilson, T. (2021). “The Economics of Small-Scale Brick Production in Developing Regions”. Journal of Construction Economics, 14(3), 201-215.

- Taylor, E. & Patel, N. (2023). “Innovation in Clay Brick Manufacturing: Case Studies from Around the World”. Global Construction Insights, 7(2), 123-138.