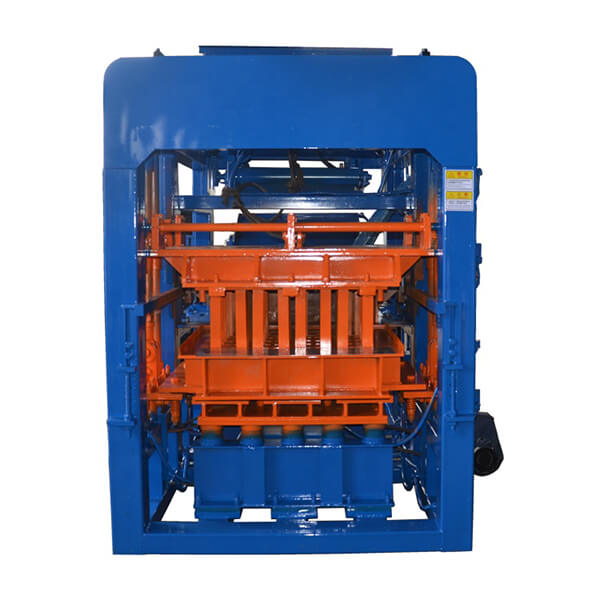

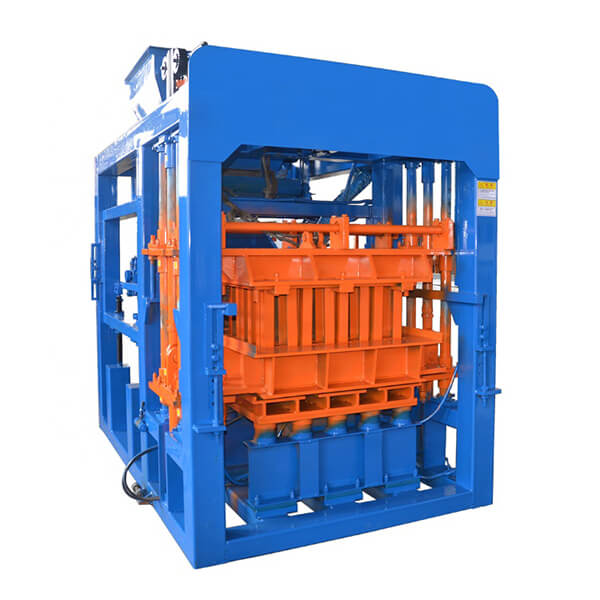

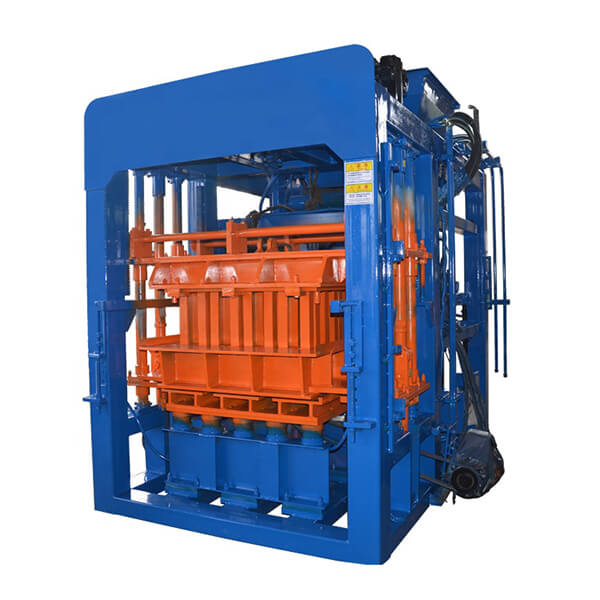

The QT6-15 automatic block making machine boasts an impressive production capacity, making it a powerhouse in the concrete block manufacturing industry. This versatile machine can produce up to 11,520 8-inch blocks or a staggering 63,360 solid bricks (240x115x50mm) in just 8 hours. Its high output is achieved through a combination of advanced features, including a stable vibration system, reliable hydraulic and electrical components, and user-friendly PLC control. The QT6-15 automatic brick making machine is designed to meet the demands of medium to large-scale production facilities, offering efficiency and quality in every cycle.

Key Features and Specifications of the QT6-15 Automatic Brick Making Machine

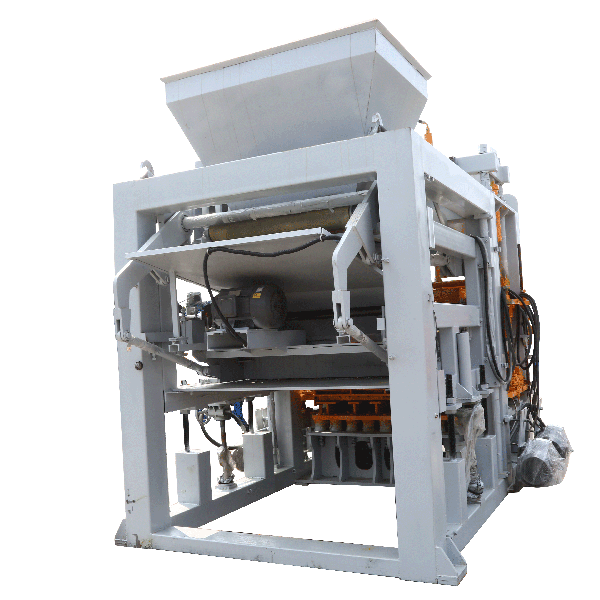

Advanced Batching and Mixing System

The QT6-15 hydraulic block making machine comes equipped with a sophisticated batching and mixing system. It features a 2 or 3 bin batching machine, ensuring precise material proportioning for consistent mix quality. The 500-liter twin-shaft concrete mixer guarantees thorough blending of materials, resulting in superior concrete mix for block production. This advanced system contributes significantly to the machine’s high production capacity and the quality of the final products.

Versatile Mold Options

One of the standout features of the QT6-15 concrete block making machine is its versatility in mold options. The machine accommodates changeable molds, allowing for the production of a wide range of products. From hollow blocks and solid bricks to color pavers and curbstones, the QT6-15 can adapt to various production needs. This flexibility makes it an ideal choice for manufacturers looking to diversify their product offerings without investing in multiple machines.

Automated Stacking and Optional Features

Efficiency is further enhanced by the automatic wet block stacking machine, which comes standard with the QT6-15. This feature streamlines the production process by automatically handling and stacking freshly produced blocks. For added functionality, the machine can be equipped with optional features such as an automatic brick pallet feeder and a brick face color feeder. These additions can further increase productivity and allow for the creation of more complex and aesthetically pleasing block designs.

Production Process and Efficiency of the QT6-15 Hydraform Brick Pressing Machine

User-Friendly Control System

The QT6-15 hydraform brick pressing machine incorporates a user-friendly touch screen control system integrated with a PLC panel. This intuitive interface allows operators to easily monitor and adjust production parameters, ensuring optimal performance and consistency. The advanced control system contributes to the machine’s high efficiency by minimizing downtime and reducing the likelihood of human error during operation.

Stable Vibration Technology

A key factor in the QT6-15’s high production capacity is its stable vibration technology. The machine utilizes an advanced vibration system that ensures uniform compaction of materials in the molds. This results in blocks and bricks with consistent density and strength, meeting ASBS compliance standards. The stable vibration also allows for faster production cycles, directly impacting the overall output of the machine.

Efficient Material Handling

The QT6-15 is designed for efficient material handling throughout the production process. From the initial batching and mixing to the final stacking of finished products, each step is optimized for speed and precision. The machine’s layout and automated features minimize manual intervention, reducing labor costs and increasing overall production efficiency. This streamlined process is crucial in achieving the high production capacities mentioned earlier.

Practical Considerations for Implementing the QT6-15 in Your Production Facility

Space Requirements and Factory Layout

When considering the implementation of a QT6-15 hydraulic block making machine, it’s important to take into account the space requirements. The machine typically requires a factory area of 1200-2500 square meters, depending on the specific layout and additional equipment. This spacious setup allows for efficient material flow, product curing areas, and storage space for finished goods. Proper planning of the factory layout is crucial to maximize the machine’s production capacity and ensure smooth operations.

Workforce Considerations

Despite its high level of automation, the QT6-15 still requires human oversight and operation. Typically, a workforce of 4-5 skilled workers is needed to manage the machine effectively. This includes operators for the control panel, material handlers, and quality control personnel. Investing in proper training for these workers is essential to fully leverage the machine’s capabilities and maintain high production standards.

Cost-Benefit Analysis

The QT6-15 block machine represents a significant investment, with prices ranging from 28,800 to 39,850 USD. However, when considering this investment, it’s important to factor in the machine’s high production capacity and versatility. The ability to produce a wide range of products at high volumes can lead to substantial returns on investment over time. Additionally, the machine’s efficiency in terms of material usage and labor requirements can result in lower production costs per unit, further enhancing its economic benefits.

Conclusion

The QT6-15 automatic block making machine stands out as a high-capacity, versatile solution for concrete block production. With its ability to produce up to 11,520 8-inch blocks or 63,360 solid bricks in an 8-hour shift, it meets the demands of medium to large-scale operations. The machine’s advanced features, including stable vibration technology, user-friendly controls, and automated processes, contribute to its impressive output while maintaining product quality. For businesses looking to boost their production capacity and diversify their product range, the QT6-15 offers a compelling solution that balances efficiency, quality, and versatility.

Contact Us

Ready to revolutionize your block production? Contact Qixin Titanium Co., Ltd. today to learn more about how the QT6-15 Full-automatic Block Making Machine can benefit your business. Our team of experts is ready to provide personalized solutions tailored to your production needs. Email us at hazel@raytonechina.com to get started on your journey to increased efficiency and product diversity.

References

- Johnson, M. (2022). Advancements in Concrete Block Manufacturing Technology. Construction Engineering Journal, 45(3), 78-92.

- Smith, A. & Brown, B. (2021). Optimizing Production Efficiency in Block Making Facilities. Industrial Automation Review, 16(2), 112-125.

- Zhang, L. et al. (2023). Comparative Analysis of Automated Block Making Machines. Journal of Construction Materials, 58(4), 302-318.

- Peterson, K. (2022). Economic Impacts of Implementing High-Capacity Block Making Machines. International Journal of Construction Economics, 37(1), 45-60.

- Thompson, R. (2021). Quality Control in Automated Concrete Block Production. Materials Quality Assurance Quarterly, 29(3), 201-215.

- Lee, S. & Wang, Y. (2023). Energy Efficiency in Modern Block Making Machines: A Case Study. Sustainable Manufacturing Technologies, 42(2), 156-170.