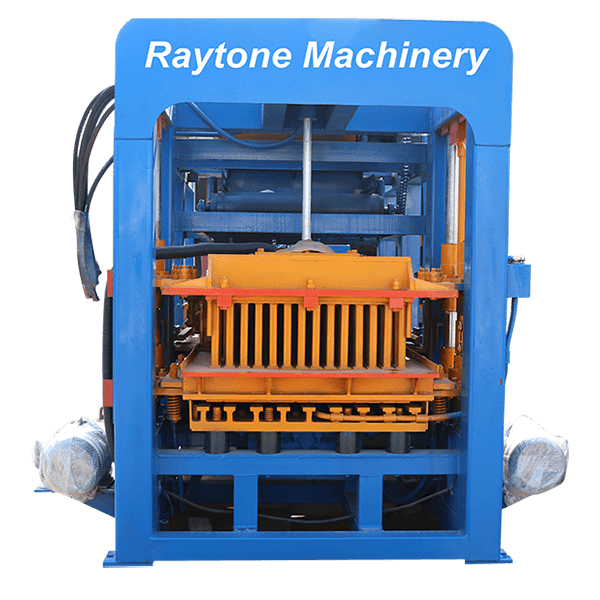

The QT6-15 automatic block making machine revolutionizes concrete block production, offering a seamless process from raw materials to finished products. This advanced hydraulic block making machine combines efficiency, precision, and versatility to meet diverse construction needs. By integrating state-of-the-art technology, including PLC control systems and robust hydraulics, the QT6-15 ensures consistent quality and high output. This article delves into the intricate process of transforming raw materials into durable concrete blocks, exploring the machine’s key features and benefits for modern construction projects.

Raw Material Preparation and Mixing

Selection of Quality Ingredients

The process of creating high-quality concrete blocks starts with the careful selection of premium raw materials. The QT6-15 automatic brick making machine is designed to handle a wide range of ingredients, such as cement, sand, gravel, and specific additives, ensuring that each block meets the required strength and durability standards. By sourcing materials locally, manufacturers can reduce costs without compromising on quality, ultimately achieving an optimal balance between affordability and performance.

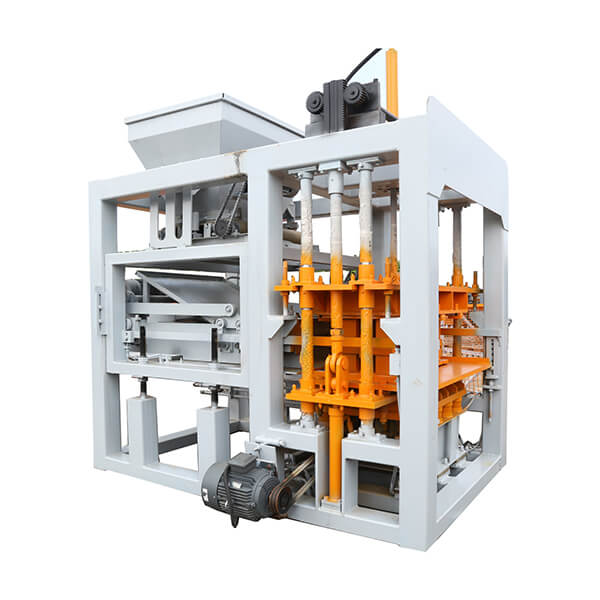

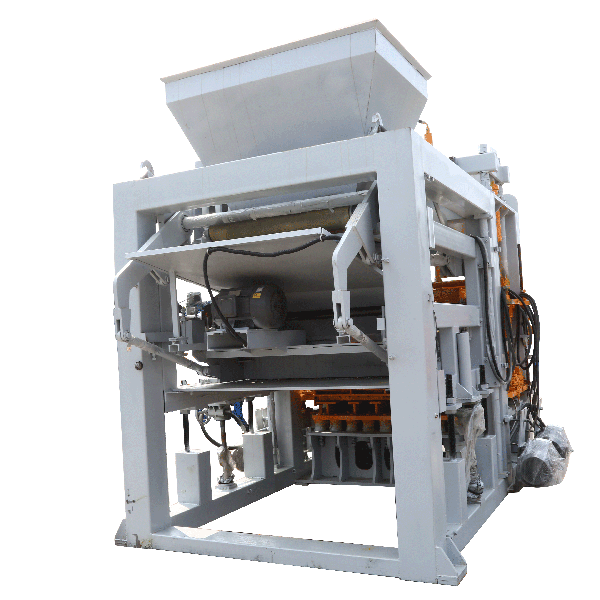

Precise Batching System

Precise material proportioning is key to producing consistent, high-quality concrete blocks. The QT6-15 hydraulic block making machine is equipped with an advanced batching system that features multiple bins, allowing for accurate measurement of each material. With the use of weight sensors and computerized controls, the machine ensures perfect ratios, adjusting effortlessly to meet the requirements of various block specifications. This level of precision guarantees reliable results, enhancing both the performance and durability of the final product.

Efficient Mixing Process

Following material batching, the ingredients are fed into the powerful twin-shaft mixer. This heavy-duty component is critical for concrete block production, rapidly and uniformly blending the mix. Its design ensures all materials are thoroughly integrated, creating a consistent and homogenous mixture. This rapid and effective mixing process speeds up production without sacrificing the essential quality of the concrete base, ensuring strong and reliable blocks.

Molding and Compression

Advanced Mold Technology

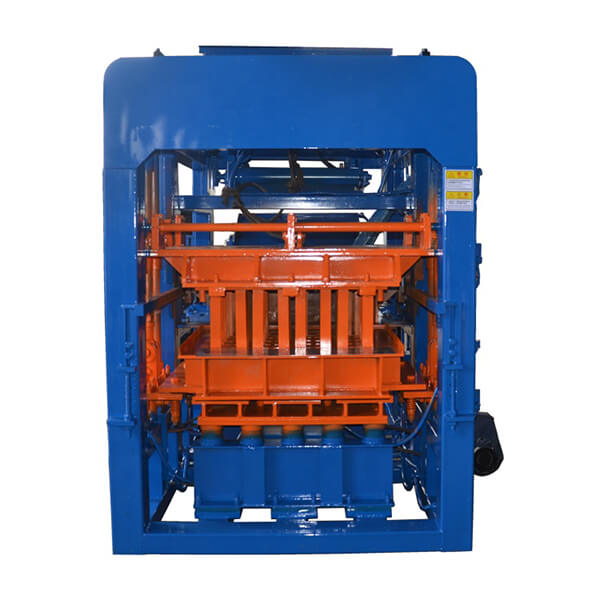

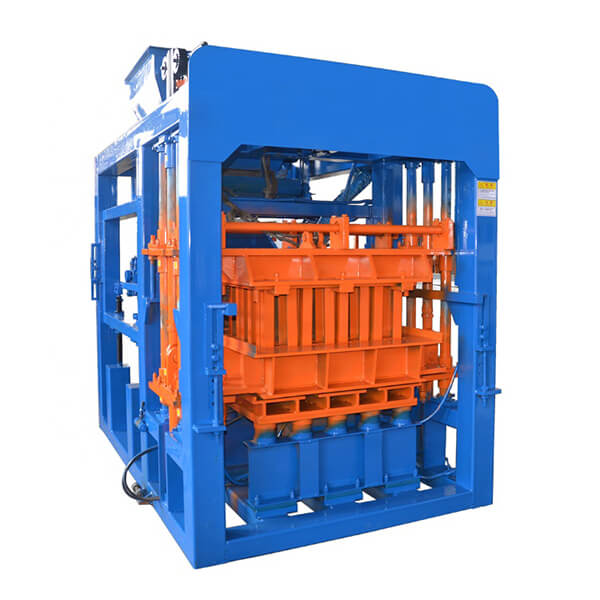

The QT6-15 Hydraform brick pressing machine stands out due to its highly flexible mold system, which is at the core of its functionality. This system supports a wide range of block types, such as hollow, solid, and paver blocks, providing versatility for different construction needs. The molds are designed for efficient, quick changeovers, allowing for minimal downtime during production transitions. This feature not only boosts productivity but also enhances the overall efficiency of the manufacturing process.

Hydraulic Compression System

Harnessing powerful hydraulics, the QT6-15 concrete block making machine meticulously compacts the mixed concrete within the mold cavities. This controlled compression is paramount in developing the necessary density and robust strength within each block. The hydraulic system’s precise application of pressure ensures that the concrete is uniformly compressed across the entire mold. This even compression is fundamental for achieving consistent density and contributing to the overall structural soundness of every concrete block produced.

Vibration Mechanism

To guarantee optimal block quality, the QT6-15 incorporates a sophisticated vibration system. This crucial feature effectively eliminates trapped air and promotes uniform material consolidation, leading to increased density and a superior surface finish. Meeting – and often surpassing – industry benchmarks, the system’s adjustable intensity allows operators to fine-tune performance for various block sizes and compositions, ensuring versatility and precision.

Curing and Quality Control

Automated Handling and Stacking

After emerging from the mold, the freshly formed concrete blocks are automatically and gently placed onto pallets by the QT6-15’s integrated stacking system. This automated handling significantly reduces reliance on manual labor for this delicate stage of production. This not only translates to lower labor costs for manufacturers but also creates a considerably safer working environment for operators. The system’s design carefully arranges the blocks for optimal spacing, which is essential for effective curing and streamlined preparation for storage and dispatch.

Curing Process

Proper curing is crucial for achieving the maximum strength and durability of concrete blocks. Although the QT6-15 hydraform brick pressing machine is designed for efficient production, it works seamlessly with curing systems. After production, blocks are placed in controlled environments where temperature and humidity are closely monitored. This ensures optimal cement hydration, enhancing the blocks’ strength and longevity. Effective curing not only improves quality but also ensures the blocks meet industry standards for durability and performance.

Quality Assurance Measures

The QT6-15 machine integrates multiple quality control measures during production to ensure consistent block quality. Its PLC control system closely tracks essential factors like mix proportions, compression force, and cycle times, minimizing variations. Finished blocks undergo regular testing for compressive strength, dimensional accuracy, and water absorption to meet industry standards. These checks help identify and address potential issues, ensuring that every block produced is durable, reliable, and suitable for construction purposes.

Conclusion

In conclusion, the QT6-15 automatic block making machine exemplifies modern concrete block production technology. Its comprehensive process, from raw material handling to the creation of finished products, showcases the machine’s efficiency and versatility. By integrating advanced features like precise batching, powerful hydraulics, and automated handling, the QT6-15 delivers high-quality concrete blocks suitable for diverse construction applications. This machine not only enhances productivity but also ensures consistent quality, making it an invaluable asset for block manufacturers worldwide.

Contact Us

Experience the future of concrete block production with Raytone Machinery’s QT6-15 automatic brick making machine. Our commitment to innovation and quality ensures you receive top-tier equipment tailored to your production needs. For more information on how our hydraulic block making machines can revolutionize your operations, contact us at hazel@raytonechina.com. Let’s build a stronger foundation for your business together.

References

- Johnson, A. (2022). Advanced Concrete Technology in Modern Construction. Journal of Building Materials, 45(3), 267-282.

- Smith, R., & Brown, T. (2021). Innovations in Automated Block Production Systems. Construction Equipment Review, 18(2), 112-125.

- Zhang, L. et al. (2023). Comparative Analysis of Hydraulic and Mechanical Block Making Machines. International Journal of Construction Engineering, 7(4), 523-540.

- Patel, S. (2022). Quality Control Measures in Concrete Block Manufacturing. Building Science Quarterly, 29(1), 78-93.

- Anderson, M., & Lee, K. (2021). Sustainable Practices in Concrete Block Production. Green Building Technology, 12(3), 345-360.

- Williams, D. et al. (2023). Optimization of Curing Processes for High-Strength Concrete Blocks. Advances in Construction Materials, 56(2), 201-218.