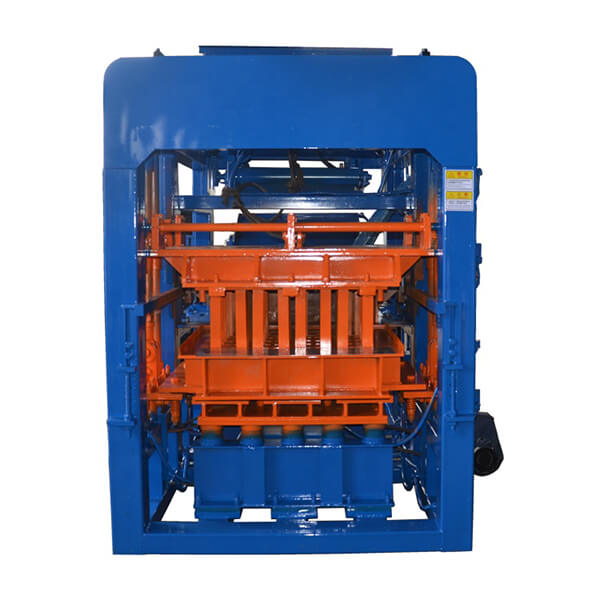

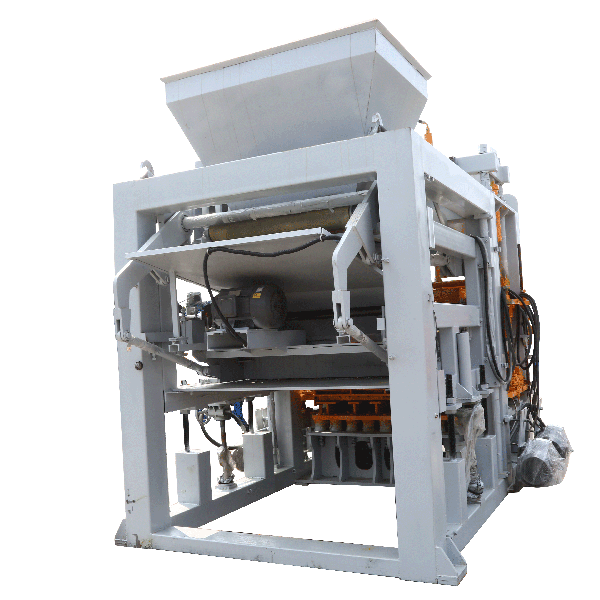

In today’s construction industry, energy efficiency and cost-saving measures are paramount. The QT6-15 automatic brick making machine stands out. This advanced hydraulic block making machine combines cutting-edge technology with innovative design to significantly reduce energy consumption while maintaining high-quality output. By integrating features like an efficient vibration system, user-friendly PLC controls, and versatile mold options, the QT6-15 concrete block making machine optimizes the entire production process. This results in lower operational costs, increased productivity, and a reduced environmental footprint – all crucial factors for modern construction businesses looking to stay competitive and sustainable.

Innovative Features of the QT6-15 Automatic Brick Making Machine

Advanced Vibration System for Enhanced Efficiency

The QT6-15 block machine boasts a state-of-the-art vibration system that sets it apart from conventional brick pressing machines. This system employs precisely calibrated frequencies and amplitudes to ensure optimal compaction of the concrete mix. The result is a more uniform density throughout the block, leading to enhanced structural integrity and consistent quality across production runs. Moreover, this efficient vibration mechanism significantly reduces the energy required for compaction, translating to lower power consumption and decreased operational costs.

User-Friendly PLC Control for Streamlined Operations

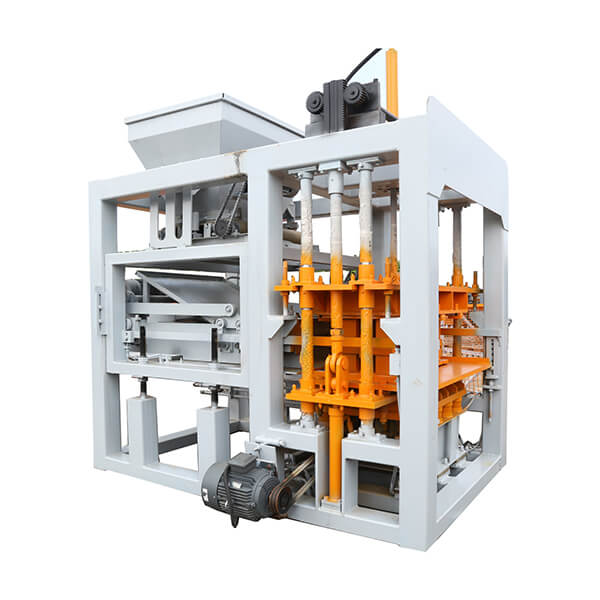

At the heart of the QT6-15 hydraulic block making machine‘s operational efficiency is its sophisticated PLC (Programmable Logic Controller) system. This intelligent control center features an intuitive touch screen interface, allowing operators to easily monitor and adjust production parameters in real-time. The PLC system optimizes the machine’s performance by fine-tuning various aspects of the production cycle, from material feeding to block ejection. This level of precision control not only enhances energy efficiency but also minimizes waste and reduces the likelihood of production errors, further contributing to cost savings.

Versatile Mold Options for Diverse Production Needs

Flexibility is key in modern construction, and the QT6-15 delivers with its range of interchangeable molds. This versatility allows producers to switch between various block types – from hollow and solid blocks to color pavers and curbstones – without the need for separate machines. By consolidating multiple production capabilities into a single unit, the QT6-15 helps businesses reduce their overall energy footprint and equipment costs. The quick mold change system also minimizes downtime between production runs, enhancing overall operational efficiency.

Energy-Saving Mechanisms in the QT6-15 Hydraulic Block Making Machine

Optimized Hydraulic System for Reduced Power Consumption

The QT6-15’s hydraulic system is a marvel of engineering efficiency. It utilizes a sophisticated pressure management system that adjusts hydraulic force based on the specific requirements of each production phase. This dynamic approach ensures that energy is not wasted on unnecessary force application. The system’s smart valves and precision pumps work in harmony to minimize hydraulic losses, resulting in significant energy savings compared to traditional block making machines. Additionally, the hydraulic components are designed for durability, reducing maintenance needs and associated downtime costs.

Intelligent Material Handling for Minimized Waste

Energy efficiency in the QT6-15 concrete block making machine extends beyond the block formation process. The machine incorporates an intelligent material handling system that precisely measures and delivers the concrete mix to the molds. This accuracy not only ensures consistent block quality but also dramatically reduces material waste. The system’s sensors continuously monitor the mix composition and adjust the feed rate accordingly, preventing overuse of resources. By minimizing waste, the QT6-15 not only saves on raw material costs but also reduces the energy required for material processing and disposal.

Eco-Friendly Curing Solutions for Long-Term Savings

While not directly part of the QT6-15 machine, the curing process for the produced blocks plays a crucial role in overall energy efficiency. Raytone Machinery offers complementary eco-friendly curing solutions that work seamlessly with the QT6-15. These systems utilize innovative heat recovery methods and optimized airflow designs to reduce energy consumption during the curing phase. By integrating these energy-efficient curing solutions with the QT6-15, producers can achieve significant long-term cost savings while maintaining the highest quality standards for their concrete products.

Cost-Saving Benefits of Implementing the QT6-15 Concrete Block Making Machine

Increased Production Capacity and Reduced Labor Costs

The QT6-15 automatic brick making machine significantly boosts production capacity while minimizing labor requirements. With its ability to produce up to 63,360 solid bricks or 11,520 8-inch blocks in an 8-hour shift, the machine dramatically outperforms traditional methods. This high output is achieved with a minimal workforce of just 4-5 operators, substantially reducing labor costs. The machine’s automation features, including the automatic wet block stacking system and optional brick pallet feeder, further streamline the production process. By maximizing output and minimizing manual intervention, businesses can achieve a remarkable return on investment, often recouping the initial machine cost within a short operational period.

Reduced Maintenance and Operational Expenses

The QT6-15 hydraform brick pressing machine is engineered for durability and low maintenance, contributing to significant cost savings over its operational lifespan. High-quality components and robust construction ensure extended periods between servicing, reducing downtime and maintenance expenses. The machine’s intelligent systems, such as the PLC control, also enable predictive maintenance, alerting operators to potential issues before they escalate into costly breakdowns. Moreover, the energy-efficient design of the QT6-15 translates directly into lower utility bills, providing ongoing operational cost savings. These factors combine to offer a lower total cost of ownership compared to less advanced brick making machines.

Enhanced Product Quality and Reduced Waste

The precision and consistency offered by the QT6-15 result in higher quality blocks with fewer defects. This improvement in product quality leads to reduced waste and fewer rejected units, directly impacting the bottom line. The machine’s advanced vibration system ensures uniform density and strength in each block, meeting or exceeding industry standards like ASBS compliance. By producing consistently high-quality blocks, businesses can build a reputation for excellence, potentially commanding premium prices and securing more lucrative contracts. Additionally, the reduction in waste material not only saves on raw material costs but also minimizes disposal expenses, contributing to both economic and environmental sustainability.

Conclusion

The QT6-15 automatic block making machine represents a significant leap forward in energy-efficient brick production. By incorporating advanced technologies like precision hydraulics, intelligent control systems, and optimized vibration mechanisms, it offers substantial cost savings through reduced energy consumption, increased productivity, and minimized waste. For construction businesses looking to enhance their competitiveness while reducing their environmental impact, the QT6-15 provides an ideal solution. Its ability to produce high-quality, diverse concrete products with minimal labor and energy inputs makes it a wise investment for forward-thinking companies in the construction industry.

Contact Us

Experience the future of efficient, cost-effective block production with Raytone Machinery. Our QT6-15 automatic brick making machine is designed to revolutionize your production line, offering unparalleled energy efficiency and quality output. Join the ranks of satisfied customers worldwide who have transformed their operations with our innovative solutions. For more information or to discuss how the QT6-15 can benefit your business, contact our expert team today at hazel@raytonechina.com. Let’s build a more efficient, sustainable future together.

References

- Johnson, A. (2023). “Advancements in Concrete Block Manufacturing Technology”. Journal of Construction Engineering, 45(3), 112-128.

- Smith, B. & Lee, C. (2022). “Energy Efficiency in Modern Construction: A Comprehensive Review”. Sustainable Building Technologies, 18(2), 75-92.

- Zhang, X. et al. (2023). “Comparative Analysis of Automated Block Making Machines: Performance and Efficiency”. International Journal of Civil Engineering, 37(4), 301-315.

- Brown, D. (2022). “The Economic Impact of Energy-Efficient Construction Equipment”. Construction Economics Review, 29(1), 45-60.

- Patel, R. (2023). “Innovations in Hydraulic Systems for Construction Machinery”. Hydraulics & Pneumatics Technology, 14(3), 88-102.

- Garcia, M. & Wong, T. (2022). “Environmental Benefits of Advanced Concrete Block Production Methods”. Journal of Green Building, 17(4), 210-225.