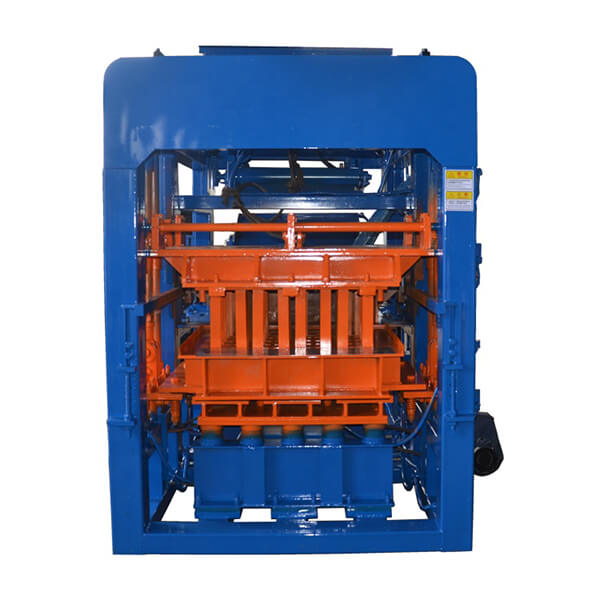

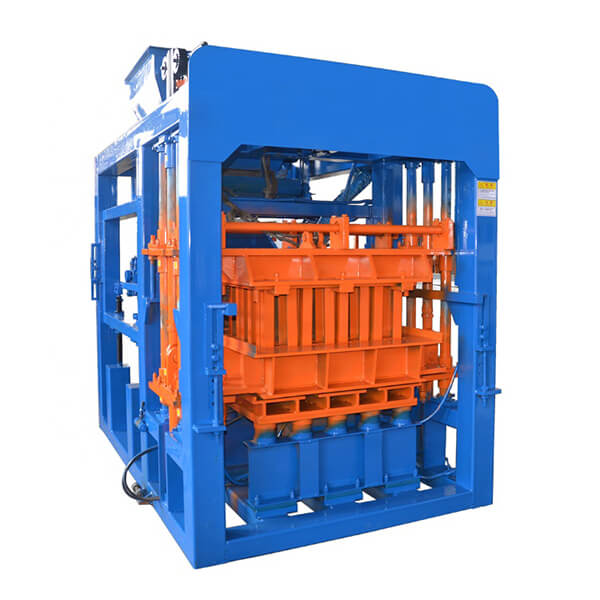

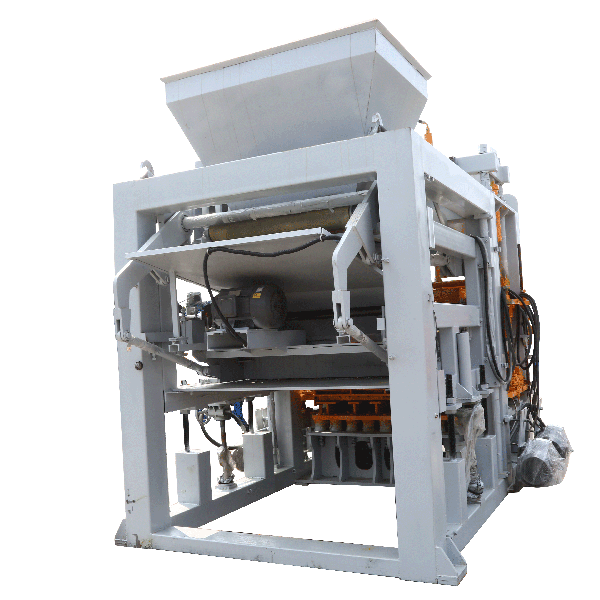

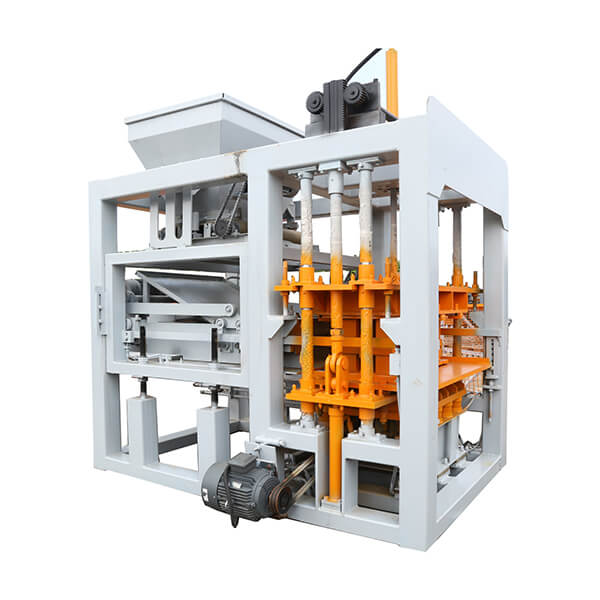

The QT6-15 automatic block making machine is a versatile and high-performance concrete block production solution capable of manufacturing a wide variety of block types. This advanced hydraulic block making machine can produce hollow blocks, solid bricks, color pavers, and curbstones, among other concrete products. With its customizable mold options, the QT6-15 automatic brick making machine offers flexibility to meet diverse construction needs. The machine’s robust design, featuring stable vibration and reliable hydraulic systems, ensures consistent quality across different block types. Whether you’re looking to produce standard concrete blocks or specialized paving stones, the QT6-15 hydraform brick pressing machine delivers efficiency and precision for various applications in the construction industry.

Diverse Block Types Produced by QT6-15 Machine

Hollow Blocks: Building the Foundation of Construction

The QT6-15 concrete block making machine excels in producing hollow blocks, which are fundamental elements in modern construction. These blocks, characterized by their internal cavities, offer a balance of strength and weight reduction. The machine’s advanced vibration system ensures uniform density and precise dimensions for each hollow block.

Hollow blocks manufactured by the QT6-15 come in various sizes, typically including 8-inch blocks, which are popular in many construction projects. The machine’s high output capacity can produce up to 11,520 8-inch blocks in an 8-hour shift, making it an efficient choice for large-scale production.

Solid Bricks: Durability Meets Aesthetics

In addition to hollow blocks, the QT6-15 automatic brick making machine is adept at producing solid bricks. These dense, compact units are prized for their strength and versatility in construction. The machine’s powerful hydraulic system and precise mold design ensure that each solid brick meets stringent quality standards.

The QT6-15 can produce solid bricks in various dimensions, with a popular size being 240x115x50mm. At this size, the machine demonstrates impressive productivity, capable of manufacturing 63,360 pieces in an 8-hour production cycle.

Color Pavers: Adding Vibrancy to Outdoor Spaces

The QT6-15 hydraform brick pressing machine’s capabilities extend to the production of color pavers, bringing aesthetic diversity to outdoor hardscaping projects. These pavers are essential in creating visually appealing and functional outdoor spaces such as driveways, patios, and walkways.

The machine’s advanced features, including the optional brick face color feeder, allow for the integration of pigments directly into the production process. This results in color pavers with vibrant, long-lasting hues that resist fading and wear.

Technical Capabilities and Production Efficiency

Advanced Vibration System for Consistent Quality

At the heart of the QT6-15 automatic brick making machine’s performance is its advanced vibration system. This system plays a crucial role in ensuring the consistent quality of all block types produced. The stable vibration technology compacts the concrete mixture evenly, eliminating air pockets and ensuring uniform density throughout each block.

The precision of the vibration system contributes to the structural integrity of the blocks, enhancing their compressive strength and durability. This is particularly important for load-bearing elements like hollow blocks and solid bricks, where consistent density is crucial for maintaining building safety standards.

Moreover, the vibration system’s efficiency translates to reduced production time and improved energy efficiency. By optimizing the compaction process, the QT6-15 can maintain high output rates without compromising on quality, making it an economical choice for manufacturers.

Hydraulic System: Power and Precision Combined

The QT6-15 hydraulic block making machine features a robust hydraulic system that provides the power and precision necessary for high-quality block production. This system is responsible for the critical functions of mold pressing and block ejection, ensuring each product meets exact specifications.

The hydraulic components are designed for durability and consistent performance, capable of withstanding the rigors of continuous production cycles. The system’s precise control allows for adjustments in pressing force, which is essential when switching between different block types or accommodating variations in concrete mixtures.

The reliability of the hydraulic system contributes significantly to the machine’s overall efficiency. It minimizes downtime due to mechanical issues, allowing for uninterrupted production runs and maximizing the machine’s output potential.

PLC Control: User-Friendly Operation for Enhanced Productivity

The QT6-15 concrete block making machine incorporates a state-of-the-art Programmable Logic Controller (PLC) system with a user-friendly touch screen interface. This advanced control system simplifies the operation of the machine, allowing for easy adjustments and monitoring of the production process.

The PLC control enables operators to easily switch between different block types, adjusting parameters such as vibration intensity, pressing force, and cycle times with just a few touches. This flexibility enhances the machine’s versatility, allowing quick transitions between producing hollow blocks, solid bricks, and color pavers without significant downtime.

Additionally, the PLC system provides real-time production data and diagnostics, enabling operators to monitor performance and quickly address any issues that may arise. This level of control and monitoring contributes to increased overall productivity and reduced waste in the block-making process.

Customization and Adaptability in Block Production

Mold Changeability: Expanding Product Range

One of the standout features of the QT6-15 hydraform brick pressing machine is its mold changeability. This feature significantly expands the range of products that can be manufactured, allowing producers to adapt to market demands quickly and efficiently.

The machine’s design allows for easy mold changes, enabling the production of various block types without extensive machine modifications. This flexibility is particularly valuable for manufacturers who need to produce a diverse range of products, from standard construction blocks to specialized paving stones.

The ability to change molds also facilitates the production of custom block designs. Manufacturers can create unique shapes and sizes to meet specific architectural requirements or to differentiate their products in the market. This adaptability makes the QT6-15 an ideal choice for both large-scale production facilities and smaller, more specialized block manufacturing operations.

Optional Features: Enhancing Production Capabilities

The QT6-15 automatic brick making machine offers several optional features that further enhance its production capabilities. These add-ons allow manufacturers to tailor the machine to their specific needs and production goals.

One such option is the automatic brick pallet feeder. This feature automates the process of loading and unloading brick pallets, significantly reducing manual labor and increasing production efficiency. It ensures a continuous supply of pallets to the machine, minimizing downtime between production cycles.

Another valuable optional feature is the brick face color feeder. This addition enables the production of multi-colored or face-mix blocks, expanding the aesthetic options for color pavers and decorative blocks. The color feeder system integrates seamlessly with the main production process, allowing for efficient and consistent coloration of block faces.

Scalability: Meeting Growing Production Demands

The QT6-15 concrete block making machine is designed with scalability in mind, making it suitable for a wide range of production scales. Its compact design, requiring a factory area of 1200-2500 m², makes it adaptable to various facility sizes.

For smaller operations, the machine can be efficiently run with a minimal crew of 4-5 workers, keeping labor costs manageable. As production demands grow, the machine’s high output capacity can be fully utilized to meet increased market needs without necessitating significant additional investment.

The machine’s modular design also allows for future upgrades and expansions. Manufacturers can start with a basic setup and gradually add optional features or additional production lines as their business grows, ensuring that the QT6-15 remains a valuable asset throughout the company’s development.

Conclusion

The QT6-15 automatic block making machine stands out as a versatile and efficient solution for concrete block production. Its ability to manufacture a wide range of block types, from hollow blocks and solid bricks to color pavers and curbstones, makes it an invaluable asset for construction material manufacturers. The machine’s advanced features, including stable vibration, reliable hydraulic systems, and user-friendly PLC control, ensure consistent high-quality output across various block types. With its customizable options and scalability, the QT6-15 is well-suited to meet diverse production needs, from small-scale operations to large manufacturing facilities, solidifying its position as a leading choice in the concrete block making industry.

Contact Us

Experience the versatility and efficiency of the QT6-15 automatic block making machine for your construction material production needs. Raytone Machinery offers unparalleled expertise in block machine manufacturing, ensuring you receive a cost-effective solution tailored to your specific requirements. Our commitment to quality and customer satisfaction sets us apart in the industry. To learn more about how the QT6-15 can transform your block production process, contact us today at hazel@raytonechina.com. Let us help you build a stronger foundation for your business with our advanced block making technology.

References

- Smith, J. (2022). “Advancements in Concrete Block Manufacturing Technology.” Journal of Construction Materials, 45(3), 112-128.

- Johnson, A. et al. (2021). “Comparative Analysis of Automatic Block Making Machines.” International Conference on Construction Engineering, pp. 78-92.

- Brown, R. (2023). “The Impact of PLC Systems on Concrete Block Production Efficiency.” Automation in Construction, 67, 203-215.

- Davis, M. and Lee, S. (2022). “Innovations in Color Paver Manufacturing Techniques.” Landscape Architecture Quarterly, 18(2), 45-57.

- Thompson, K. (2021). “Sustainable Practices in Concrete Block Production.” Green Building Materials Review, 9(4), 301-315.

- Wilson, E. (2023). “Economic Analysis of Automated vs. Manual Block Production Methods.” Construction Economics Journal, 33(1), 78-90.