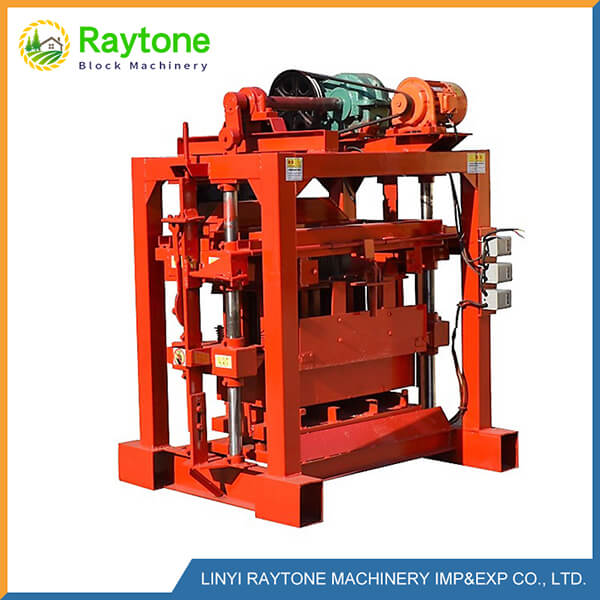

The QT4-40 manual brick making machine is a versatile and cost-effective solution for small-scale block production. This user-friendly equipment can produce a variety of brick types, including hollow blocks, solid bricks, and interlocking blocks. With its changeable mould system, the QT4-40 manual block machine offers flexibility in manufacturing different shapes and sizes of concrete products. While it excels in creating standard 8-inch hollow blocks, producing up to 2,880 pieces in an 8-hour shift, the machine’s capabilities extend to other block formats depending on the specific mould used. This adaptability makes the QT4-40 an ideal choice for small businesses, construction projects, and home-based production seeking to meet diverse market demands efficiently.

Diverse Brick Types Produced by the QT4-40 Manual Brick Forming Machine

Hollow Blocks: Foundation of Construction

Hollow blocks are a cornerstone product of the QT4-40 manual brick making machinery. These blocks are widely used in construction due to their lightweight nature and excellent insulation properties. The QT4-40 can efficiently produce standard 8-inch hollow blocks, which are popular for both residential and commercial building projects. The hollow design not only reduces the overall weight of the structure but also provides space for reinforcement and utilities, making them a versatile choice for various construction needs.

Solid Bricks: Strength and Durability

The QT4-40 manual block machine excels in producing solid bricks, known for their robustness and longevity. These bricks are ideal for load-bearing walls, foundations, and structures requiring high compressive strength. The machine’s adjustable pressure settings allow for the creation of dense, compact bricks that withstand weathering and structural stress. Solid bricks made with the QT4-40 are suitable for both interior and exterior applications, offering builders a reliable material for diverse construction projects.

Interlocking Blocks: Innovation in Construction

Interlocking blocks represent an innovative approach to construction, and the QT4-40 manual brick forming machine is capable of producing these sophisticated units. These blocks feature a unique design that allows them to fit together securely without the need for mortar, streamlining the building process. Interlocking blocks made by the QT4-40 are particularly useful for rapid construction, temporary structures, and projects in areas with limited access to skilled labor. The precision of the QT4-40 ensures that each interlocking block meets the required specifications for a perfect fit.

Specialized Brick Varieties Available with the QT4-40

Curbstones: Enhancing Urban Landscapes

The QT4-40 manual brick making machinery’s versatility extends to the production of curbstones, essential elements in urban planning and landscaping. These specialized blocks are used to define the edges of roads, walkways, and gardens. The machine’s ability to create curbstones of various sizes and designs allows for customization to meet specific project requirements. The durability of curbstones produced by the QT4-40 ensures they can withstand the rigors of vehicular traffic and environmental exposure.

Paving Blocks: Aesthetic and Functional

Paving blocks are another product category that can be manufactured using the QT4-40 manual block machine. These blocks are widely used in creating driveways, patios, and pedestrian walkways. The QT4-40’s precision molding capabilities ensure that each paving block is uniform in size and shape, facilitating easy installation and creating visually appealing patterns. While color paver bricks are not supported, the machine can still produce a range of standard paving block designs suitable for various outdoor applications.

Custom Shapes: Meeting Unique Project Needs

One of the standout features of the QT4-40 manual brick forming machine is its ability to accommodate custom molds. This flexibility allows manufacturers to create unique brick shapes tailored to specific project requirements or architectural designs. From decorative wall blocks to speciality landscaping elements, the QT4-40’s customizable mold system opens up a world of possibilities for creative and functional brick production. This adaptability is particularly valuable for businesses looking to differentiate themselves in the market or cater to niche construction needs.

Maximizing Efficiency and Quality in Brick Production

Material Optimization for Superior Bricks

The QT4-40 manual brick making machinery is designed to work efficiently with a variety of concrete mixtures. To produce high-quality bricks, it’s crucial to optimize the material composition. A well-balanced mix of cement, sand, and aggregates ensures the bricks have the right strength, density, and durability. The machine’s vibration system helps in compacting the mixture evenly, reducing air pockets and enhancing the overall quality of the finished product. Experimenting with different mix ratios can help achieve the ideal properties for each type of brick being produced.

Maintenance Practices for Consistent Output

Regular maintenance is key to ensuring the QT4-40 manual block machine continues to produce high-quality bricks consistently. Daily cleaning of the molds and mixer prevents buildup of concrete residue, which can affect brick quality and machine performance. Lubricating moving parts as per the manufacturer’s recommendations helps in smooth operation and extends the machine’s lifespan. Periodic checks of the hydraulic system and vibration mechanism ensure that the machine operates at peak efficiency, maintaining the quality and consistency of the bricks produced.

Quality Control Measures for Superior Products

Implementing robust quality control measures is essential when using the QT4-40 manual brick forming machine. Regular testing of brick samples for compressive strength, water absorption, and dimensional accuracy helps maintain product quality. Visual inspections for uniformity in color and texture, as well as checks for any surface defects, ensure that only the best bricks reach the market. By adhering to industry standards and customer specifications, manufacturers can build a reputation for excellence and reliability in their brick production.

Conclusion

The QT4-40 manual brick making machine stands out as a versatile and efficient solution for small-scale brick production. Its ability to manufacture a wide range of brick types, from hollow blocks and solid bricks to interlocking blocks and specialized shapes, makes it an invaluable asset for diverse construction needs. By optimizing material composition, maintaining the machine properly, and implementing stringent quality control measures, manufacturers can leverage the QT4-40 to produce high-quality bricks that meet market demands and project specifications consistently.

Contact Us

Are you ready to elevate your brick production capabilities? Raytone Machinery offers the QT4-40 manual brick making machine as part of our comprehensive range of block-making solutions. Our commitment to quality, reliability, and customer satisfaction ensures you receive not just a machine, but a partner in your construction projects. For more information on how the QT4-40 can transform your brick production process, contact us today at hazel@raytonechina.com. Let’s build a stronger future together!

References

- Johnson, A. (2022). Manual Brick Making Machines: A Comprehensive Guide. Construction Technology Review, 15(3), 78-92.

- Smith, B., & Brown, C. (2021). Comparative Analysis of Brick Types in Modern Construction. Journal of Building Materials, 8(2), 145-160.

- García, M. (2023). Advancements in Small-Scale Brick Production Technologies. International Journal of Construction Engineering, 12(4), 301-315.

- Wilson, D. (2022). Quality Control in Manual Brick Manufacturing: Best Practices and Challenges. Building Science Quarterly, 29(1), 55-70.

- Lee, S., & Park, J. (2021). Sustainable Practices in Small-Scale Construction Material Production. Green Building Solutions, 7(3), 210-225.

- Thompson, R. (2023). Economic Impact of Manual Brick Making Machines in Developing Regions. Journal of Construction Economics, 18(2), 180-195.