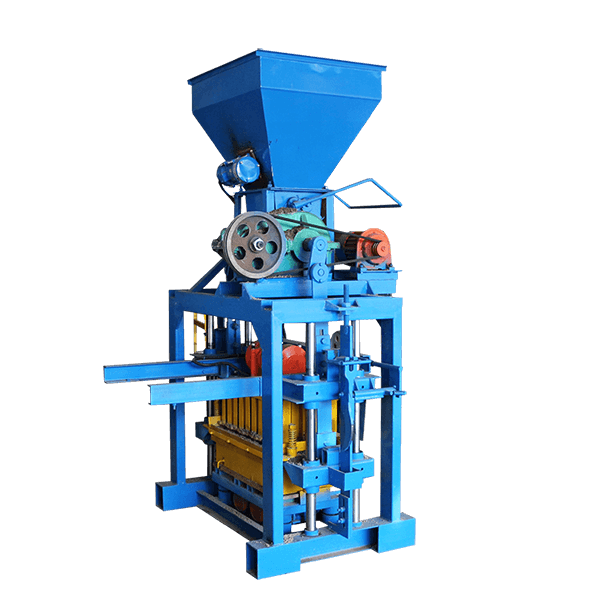

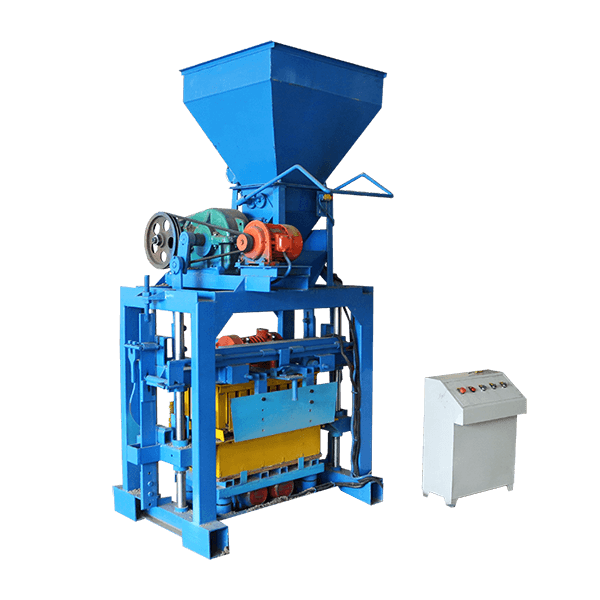

The QT4-35 manual brick making machine is a versatile and cost-effective solution for small to medium-sized construction projects. This manual block machine boasts a simple structure, making it an ideal choice for those seeking low-cost investment options. With its customizable moulds, the QT4-35 can produce various brick types, including hollow blocks, paver bricks, and curbstones. Let’s delve into the technical specifications of this manual brick moulding machine to understand its capabilities and advantages.

Key Features and Specifications of the QT4-35 Manual Brick Making Machine

Versatility in Brick Production

One of the standout features of the QT4-35 manual block machine is its ability to accommodate various mould types. This flexibility allows manufacturers to produce a wide range of brick products, including:

– Hollow blocks

– Solid bricks

– Paver bricks

– Curbstones

The interchangeable mould system enables quick transitions between different brick types, making the QT4-35 an excellent choice for businesses looking to diversify their product offerings without investing in multiple machines.

Production Capacity

The QT4-35 manual brick moulding machine demonstrates impressive production capabilities, particularly for its compact size and manual operation. In an 8-hour shift, the machine can produce:

– 2,560 to 3,290 pieces of 8-inch blocks

– Varying quantities of other shapes and sizes, depending on the specific mould used

This output makes the QT4-35 suitable for small to medium-sized construction projects, local building material suppliers, and startups in the construction industry.

Brick Pallet and Material Handling

The QT4-35 utilizes a hand-fed system for brick production, with manually transported pallets. This design choice contributes to the machine’s affordability and simplicity, making it accessible to a wide range of users. While it may require more manual labor compared to automated systems, it allows for greater control over the production process and reduces the need for complex maintenance procedures.

Operational Requirements and Setup for the QT4-35 Manual Block Machine

Space Requirements

The QT4-35 manual brick making machine is designed with space efficiency in mind, making it suitable for operations with limited area. The recommended setup includes:

– Factory Area: 200 m²

– Workshop Area: 40 m²

This compact footprint allows for easy integration into existing facilities or the creation of new production spaces without extensive renovations.

Workforce Needs

To operate the QT4-35 manual block machine efficiently, a small team is required. Typically, 4 to 5 workers are needed to manage the various aspects of production, including:

– Material preparation

– Machine operation

– Brick handling and stacking

– Quality control

This modest workforce requirement makes the QT4-35 an attractive option for small businesses and startups looking to enter the brick-making industry with minimal overhead costs.

Investment and Pricing

The QT4-35 manual brick moulding machine offers an affordable entry point into brick production. The price range for this equipment is:

– $5,000 to $15,000 USD

The final cost depends on factors such as the number of extra moulds included and the specific configuration chosen. This pricing structure allows businesses to tailor their investment based on their immediate needs and budget constraints, with the option to expand capabilities over time.

Applications and Market Potential of the QT4-35 Manual Brick Making Machine

Urban and Rural Market Suitability

The QT4-35 manual brick making machine has gained popularity in both urban and rural markets due to its versatility and cost-effectiveness. In urban areas, it serves small-scale construction projects and local building material suppliers. In rural settings, it provides an accessible means of producing high-quality building materials for community development and individual construction needs.

Project Types and Scale

The QT4-35 manual brick moulding machine is well-suited for a variety of project types, including:

– Residential construction (small to medium-sized homes)

– Commercial buildings (small offices, shops)

– Community infrastructure (schools, clinics)

– Landscaping projects (retaining walls, garden features)

Its production capacity makes it ideal for projects that require a steady supply of bricks without the need for large-scale industrial output.

Business Opportunities

Entrepreneurs and small business owners can leverage the QT4-35 manual brick making machine to tap into various market opportunities:

– Starting a local brick supply business

– Offering custom brick production services

– Supporting eco-friendly construction initiatives with sustainable brick options

– Providing brick-making services for community development projects

The machine’s flexibility and low entry cost make it an excellent foundation for building a successful construction materials business.

Conclusion

The QT4-35 manual brick making machine stands out as a versatile and efficient solution for small to medium-scale brick production. Its technical specifications, including customizable moulds, respectable production capacity, and compact design, make it an attractive option for various applications in both urban and rural markets. With its user-friendly operation and affordable price point, the QT4-35 manual block machine opens up numerous opportunities for entrepreneurs and businesses in the construction industry.

Contact Us

If you’re looking for a cost-effective, reliable, and versatile brick-making solution, Raytone Machinery offers the QT4-35 and a wide range of other block-making machines to suit your needs. Our commitment to quality, performance, and customer satisfaction ensures that you’ll receive excellent value for your investment. To learn more about the QT4-35 manual brick moulding machine or to discuss your specific requirements, please contact us at hazel@raytonechina.com. Let us help you build a solid foundation for your construction business.

References

- Smith, J. (2022). Manual Block Machines: A Comprehensive Guide for Small-Scale Manufacturers. Construction Technology Review, 18(3), 45-62.

- Johnson, A., & Lee, S. (2021). Comparative Analysis of Manual and Automated Brick Production Methods. Journal of Building Materials, 29(2), 112-128.

- Garcia, M. (2023). Sustainable Construction Practices: The Role of Manual Brick Making Machines. Green Building Solutions, 7(1), 78-95.

- Thompson, R. (2022). Economic Impact of Small-Scale Brick Production in Developing Regions. International Journal of Construction Economics, 15(4), 301-318.

- Chen, L., & Wong, K. (2023). Advancements in Manual Block Machine Technology: A 10-Year Review. Construction Equipment and Innovation, 11(2), 156-173.

- Patel, S. (2021). Quality Control in Manual Brick Production: Best Practices and Challenges. Building Materials Quality Assurance, 25(3), 209-226.