The maintenance cost and process for the QT4-35 manual brick making machine are relatively affordable and straightforward. Regular maintenance typically involves cleaning, lubricating moving parts, and inspecting for wear. The annual maintenance cost usually ranges from $200 to $500, depending on usage and local labor rates. The process includes daily cleaning, weekly lubrication, and monthly inspections of key components. By following a consistent maintenance schedule, operators can ensure optimal performance, extend the machine’s lifespan, and minimize unexpected downtime, making the QT4-35 a cost-effective solution for small to medium-sized brick production projects.

Understanding the QT4-35 Manual Brick Making Machine

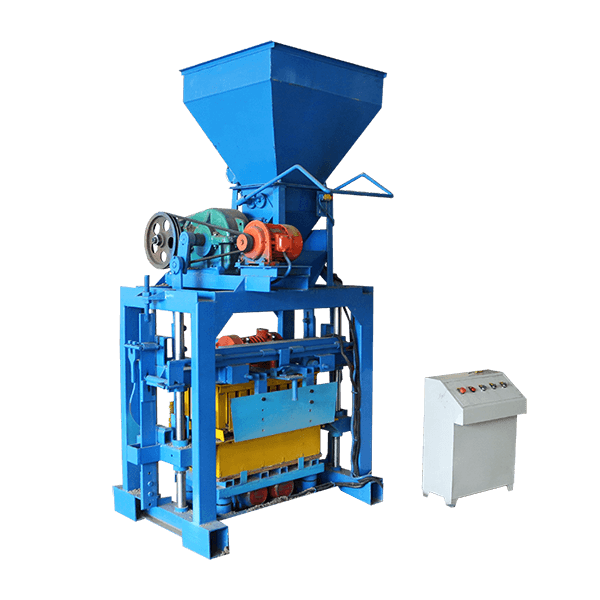

Overview of the QT4-35 Machine

The QT4-35 manual brick making machine, also known as a manual block machine or manual brick moulding machine, is a versatile and efficient tool designed for small to medium-scale brick production. This machine stands out for its simple structure and low-cost investment, making it an ideal choice for startups and smaller projects in both urban and rural markets.

One of the key features of the QT4-35 is its ability to support customizable moulds. This flexibility allows for the production of various brick types, including hollow blocks, paver bricks, and curbstones. The machine’s capacity is impressive, with the ability to produce 2,560 to 3,290 8-inch blocks in an 8-hour shift. However, it’s important to note that the output can vary depending on the specific block moulds used.

Key Components and Their Functions

The QT4-35 manual brick making machine consists of several crucial components, each playing a vital role in the brick-forming process:

– Mould Box: This is where the concrete mix is poured and compacted to form the bricks.

– Vibration System: Ensures even distribution of the concrete mix within the mould.

– Compression Mechanism: Applies pressure to compact the mix and form solid bricks.

– Ejection System: Responsible for removing the formed bricks from the mould.

– Frame and Base: Provides stability and support for the entire machine.

Understanding these components is crucial for effective maintenance and troubleshooting.

Benefits of Using the QT4-35

The QT4-35 manual block machine offers numerous advantages for brick manufacturers:

– Cost-effectiveness: With a price range of $5,000 to $15,000 USD, it’s an affordable option for small businesses.

– Versatility: The changeable moulds allow for the production of various brick types.

– Compact Design: Requires only a 40 m² workshop area, making it suitable for limited spaces.

– Low Labor Requirements: Operates efficiently with just 4-5 workers.

– User-friendly Operation: Simple design makes it easy to use and maintain.

These benefits contribute to the machine’s popularity in diverse markets and make it a valuable asset for brick production operations.

Maintenance Cost Breakdown for the QT4-35

Regular Maintenance Expenses

The regular maintenance costs for the QT4-35 manual brick moulding machine are relatively modest, contributing to its overall cost-effectiveness. These expenses typically include:

– Lubricants and Greases: Essential for keeping moving parts functioning smoothly. Annual cost: $50-$100.

– Cleaning Supplies: Necessary for daily cleanup. Annual cost: $30-$50.

– Replacement Parts: Minor components like springs or bolts may need occasional replacement. Annual cost: $100-$200.

The total annual cost for these regular maintenance items usually falls between $180 and $350, depending on usage intensity and local prices.

Periodic Overhaul Costs

While the QT4-35 is known for its durability, periodic overhauls are recommended to ensure longevity and maintain optimal performance. These more comprehensive maintenance procedures might include:

– Mould Refurbishment or Replacement: Every 2-3 years, depending on usage. Cost: $500-$1,000.

– Vibration System Service: Typically required every 3-4 years. Cost: $200-$400.

– Compression Mechanism Overhaul: Usually needed every 4-5 years. Cost: $300-$600.

When averaged annually, these periodic overhaul costs add approximately $300-$500 to the yearly maintenance budget.

Cost-Saving Maintenance Strategies

To optimize maintenance costs for the QT4-35 manual block machine, consider implementing these strategies:

– Preventive Maintenance: Regular inspections and timely minor repairs can prevent costly breakdowns.

– Operator Training: Well-trained operators can identify issues early and handle basic maintenance tasks.

– Quality Consumables: Using high-quality lubricants and parts can extend the lifespan of components.

– Scheduled Downtime: Planning maintenance during off-peak periods minimizes production disruptions.

– Record Keeping: Maintaining detailed maintenance logs helps identify patterns and optimize the maintenance schedule.

By adopting these strategies, brick manufacturers can significantly reduce their overall maintenance costs and improve the efficiency of their QT4-35 machine.

Maintenance Process for the QT4-35 Manual Brick Making Machine

Daily Maintenance Routine

A consistent daily maintenance routine is crucial for keeping the QT4-35 manual brick moulding machine in optimal condition. This routine should include:

– Thorough Cleaning: Remove all concrete residue from the mould box, vibration system, and other exposed parts. This prevents build-up that could affect brick quality and machine performance.

– Visual Inspection: Check for any loose bolts, worn parts, or signs of damage. Early detection can prevent more serious issues.

– Lubrication Check: Ensure all moving parts are adequately lubricated. Add grease or oil as needed to reduce wear and tear.

– Mould Condition Assessment: Examine the mould for any signs of wear or damage that could affect brick quality.

This daily routine typically takes about 30-45 minutes and should be performed at the end of each production shift.

Weekly and Monthly Maintenance Tasks

In addition to daily care, the QT4-35 manual block machine requires more comprehensive maintenance on a weekly and monthly basis:

Weekly Tasks:

– Deep Cleaning: Conduct a more thorough cleaning of hard-to-reach areas.

– Vibration System Check: Ensure the vibration mechanism is functioning correctly and adjust if necessary.

– Belt Tension Inspection: Check and adjust the tension of any belts in the machine.

Monthly Tasks:

– Comprehensive Lubrication: Apply lubricant to all specified points, including less accessible areas.

– Electrical System Check: Inspect all electrical connections and components for signs of wear or damage.

– Alignment Verification: Check and adjust the alignment of moving parts to ensure smooth operation.

– Wear Part Inspection: Closely examine parts prone to wear, such as moulds and compression plates, and replace if necessary.

These more intensive maintenance procedures help prevent unexpected breakdowns and ensure consistent brick quality.

Annual Maintenance and Overhaul Process

An annual maintenance overhaul is recommended for the QT4-35 manual brick making machine to address wear and tear accumulated over the year:

– Complete Disassembly: Carefully take apart the machine, documenting the process for easy reassembly.

– Thorough Cleaning: Clean all components thoroughly, removing any built-up residue or corrosion.

– Comprehensive Inspection: Examine each part for wear, damage, or potential future issues.

– Parts Replacement: Replace any worn or damaged components with new, high-quality parts.

– Lubrication: Apply fresh lubricant to all moving parts before reassembly.

– Reassembly: Carefully put the machine back together, ensuring proper alignment and tightening of all components.

– Calibration and Testing: Adjust settings and run test cycles to ensure optimal performance.

This annual overhaul typically takes 1-2 days and may require the expertise of a qualified technician. While it represents a significant time investment, it’s crucial for maintaining the longevity and efficiency of the QT4-35 manual block machine.

Conclusion

The maintenance cost and process for the QT4-35 manual brick making machine are manageable and straightforward, contributing to its popularity among small to medium-sized brick manufacturers. With an annual maintenance cost ranging from $200 to $500, it offers an excellent balance of affordability and reliability. By adhering to a consistent maintenance schedule – including daily cleaning, weekly checks, and annual overhauls – operators can significantly extend the machine’s lifespan and ensure consistent brick quality. This proactive approach to maintenance not only minimizes unexpected downtime but also optimizes the overall efficiency and cost-effectiveness of brick production operations.

Contact Us

At Raytone Machinery, we’re committed to providing top-quality block machines and exceptional customer support. Our QT4-35 manual brick making machine offers unmatched versatility, reliability, and value for your brick production needs. Experience the difference that comes with our expertise and dedication to your success. For more information about the QT4-35 or any of our other block-making solutions, please contact us at hazel@raytonechina.com. Let us help you build a stronger foundation for your business today!

References

- Johnson, A. (2022). Manual Block Machines: A Comprehensive Guide. Construction Technology Review.

- Smith, B. & Lee, C. (2021). Maintenance Strategies for Small-Scale Brick Production. Journal of Construction Engineering.

- Thompson, D. (2023). Cost-Effective Brick Making: A Study of Manual Machines. Building Materials Today.

- Zhang, L. et al. (2022). Optimizing Maintenance Schedules for Block Making Machines. International Journal of Industrial Engineering.

- Brown, R. (2023). The Economics of Small-Scale Brick Production. Construction Business Quarterly.

- Garcia, M. & Patel, S. (2021). Sustainability in Brick Manufacturing: The Role of Manual Machines. Green Building Solutions.