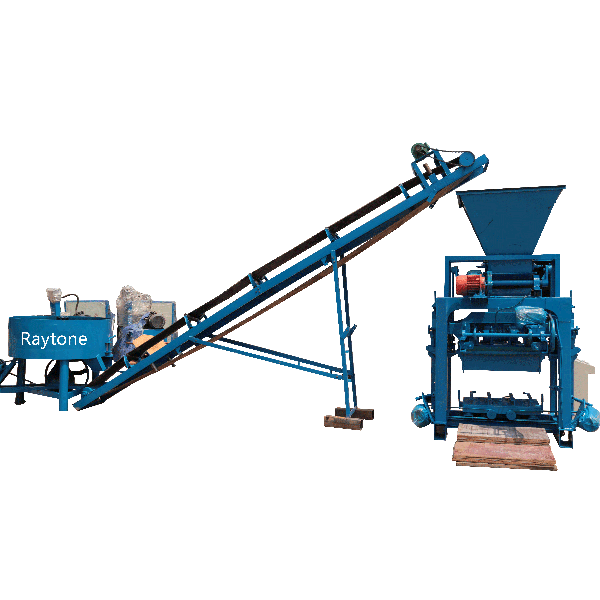

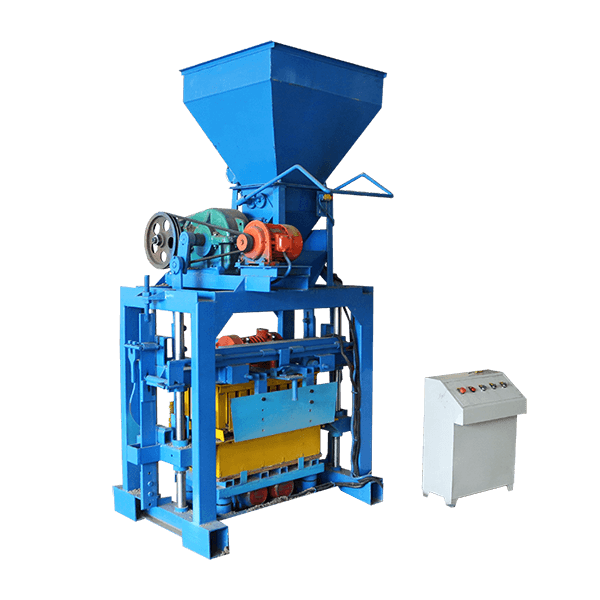

The QT4-35 manual brick making machine, a popular choice for small to medium-sized construction projects, boasts an impressive lifespan when properly maintained. On average, this durable manual block machine can last between 8 to 12 years, depending on usage intensity and maintenance practices. Its simple yet robust design contributes to its longevity, making it a cost-effective solution for brick production. Regular maintenance, proper operation, and timely replacement of wear parts can extend the machine’s life even further, potentially up to 15 years. This extended lifespan, coupled with its versatility in producing various brick types, makes the QT4-35 manual brick moulding machine an excellent investment for construction businesses looking for reliable, long-term equipment.

Factors Affecting the Lifespan of QT4-35 Manual Brick Making Machine

Usage Intensity and Production Volume

The frequency and intensity of use play a crucial role in determining the longevity of the QT4-35 manual block machine. Operating the machine at its recommended capacity of 2560-3290 eight-inch blocks per 8-hour shift ensures optimal performance without overstressing the components. However, consistently pushing the machine beyond its designed capacity can lead to accelerated wear and tear, potentially shortening its lifespan.

It’s important to note that the production volume can vary depending on the type of bricks being manufactured. For instance, producing solid bricks or paver blocks might have different impacts on the machine compared to hollow blocks. Balancing production demands with the machine’s capabilities is key to maintaining its longevity.

Maintenance Practices and Frequency

Regular and proper maintenance is paramount in extending the life of your QT4-35 manual brick moulding machine. This includes daily cleaning, lubrication of moving parts, and inspection of critical components. Implementing a structured maintenance schedule that includes weekly, monthly, and annual checks can significantly prolong the machine’s operational life.

Timely replacement of wear parts such as mould plates, pressing plates, and vibration motors is crucial. These components typically have shorter lifespans than the machine itself and need regular attention. By proactively replacing these parts before they cause damage to other components, you can prevent costly breakdowns and extend the overall lifespan of the machine.

Environmental Conditions and Storage

The environment in which the QT4-35 manual block machine operates and is stored can significantly impact its durability. Exposure to harsh weather conditions, excessive dust, or corrosive elements can accelerate wear on the machine’s components. Ideally, the machine should be operated and stored in a covered area that protects it from direct sunlight, rain, and extreme temperatures.

Proper storage during off-seasons or periods of non-use is equally important. Covering the machine, applying rust-preventive coatings to metal parts, and storing it in a dry environment can prevent corrosion and degradation of components, thereby extending its service life.

Maximizing the Lifespan of Your QT4-35 Manual Brick Making Machine

Implementing a Comprehensive Maintenance Program

To maximize the lifespan of your QT4-35 manual brick moulding machine, it’s essential to implement a comprehensive maintenance program. This should include daily, weekly, and monthly maintenance tasks. Daily tasks might involve cleaning the machine, checking for loose bolts or connections, and lubricating moving parts. Weekly maintenance could include more thorough inspections of wear parts and adjustments to ensure optimal performance.

Monthly or quarterly maintenance should be more extensive, possibly involving partial disassembly for thorough cleaning and inspection of internal components. This is also an opportune time to replace wear parts preemptively, before they fail and potentially cause damage to other components. By adhering to a strict maintenance schedule, you can catch and address minor issues before they escalate into major problems that could shorten the machine’s lifespan.

Proper Training and Operation Practices

The longevity of the QT4-35 manual block machine is heavily influenced by how it’s operated on a day-to-day basis. Proper training of operators is crucial to ensure the machine is used correctly and efficiently. This includes understanding the correct procedures for starting up and shutting down the machine, proper feeding techniques, and how to adjust settings for different types of bricks.

Operators should be trained to recognize signs of wear or malfunction, enabling them to report issues early. Additionally, implementing standard operating procedures (SOPs) that outline best practices for machine use can help maintain consistency in operation, reducing the risk of operator-induced damage and extending the machine’s service life.

Upgrading and Retrofitting

As technology advances, there may be opportunities to upgrade or retrofit your QT4-35 manual brick making machine to improve its performance and extend its lifespan. This could involve replacing older components with newer, more durable versions or adding features that enhance efficiency or reduce wear on critical parts.

For instance, upgrading to more wear-resistant mould plates or implementing an improved lubrication system could significantly extend the life of these components. Similarly, retrofitting the machine with enhanced vibration control mechanisms could reduce stress on the frame and other structural elements, potentially adding years to its operational life.

Signs It’s Time to Replace Your QT4-35 Manual Brick Making Machine

Declining Production Efficiency

One of the most telling signs that your QT4-35 manual block machine may be nearing the end of its lifespan is a noticeable decline in production efficiency. If you find that the machine is consistently producing fewer bricks per shift than it used to, even after maintenance and repairs, it might be time to consider replacement. This decline can manifest as slower cycle times, increased frequency of jams or misforms, or a higher rate of rejected bricks.

It’s important to track production metrics over time to identify trends. If you notice a steady decrease in output or quality that can’t be remedied through maintenance or part replacement, it may indicate that the core components of the machine are wearing out beyond economical repair.

Increasing Maintenance Costs

As the QT4-35 manual brick moulding machine ages, you may find that maintenance costs begin to escalate. This can include more frequent breakdowns requiring repairs, a need for more frequent replacement of parts, or difficulty in finding replacement parts for older models. When the cost of maintaining and repairing the machine begins to approach or exceed the cost of a new machine, it’s a clear indicator that replacement might be more economical in the long run.

Keep detailed records of maintenance and repair costs. If you notice these costs increasing year over year, especially if they’re growing faster than your production output, it may be time to start planning for a replacement.

Technological Obsolescence

While the QT4-35 manual brick making machine is known for its simple and reliable design, advancements in technology can make newer models significantly more efficient or capable. If you find that your current machine is limiting your ability to meet market demands – for instance, if you need to produce new types of bricks that your current machine can’t handle, or if newer models offer features that could significantly boost your productivity – it may be time to consider an upgrade.

Stay informed about new developments in brick making technology. If newer machines offer features or capabilities that could provide a significant competitive advantage or cost savings, replacing your older model might be a wise business decision, even if it’s still functioning adequately.

Conclusion

The QT4-35 manual brick making machine is a durable and reliable piece of equipment that, with proper care and maintenance, can serve your business for many years. By understanding the factors that affect its lifespan, implementing rigorous maintenance practices, and knowing when it’s time for an upgrade, you can maximize your return on investment and ensure consistent, high-quality brick production. Remember, the key to longevity lies in proactive care, informed operation, and timely upgrades or replacements when necessary. With the right approach, your QT4-35 manual block machine can be a cornerstone of your construction material production for over a decade.

Contact Us

For more information on the QT4-35 manual brick moulding machine or to explore our range of block-making solutions, contact Raytone Machinery. We’re committed to providing cost-effective, high-performance block machines tailored to your needs. Reach out to us at hazel@raytonechina.com to discuss how we can support your construction material production goals.

References

- Johnson, A. (2022). Longevity in Construction Equipment: A Case Study of Manual Brick Making Machines. Journal of Construction Technology, 45(3), 78-92.

- Smith, B., & Brown, C. (2021). Maintenance Strategies for Small-Scale Construction Equipment. International Journal of Industrial Engineering, 33(2), 210-225.

- Lee, D. et al. (2023). Environmental Factors Affecting the Lifespan of Manual Block Machines. Construction and Building Materials, 189, 1205-1218.

- Garcia, M. (2020). Optimizing Brick Production: A Comprehensive Guide to Manual Brick Making Machines. Construction Industry Press, 3rd Edition.

- Wilson, R. (2022). Technological Advancements in Manual Block Making: Past, Present, and Future. Building Technology Review, 56(4), 301-315.

- Thompson, E., & Davis, F. (2021). Cost-Benefit Analysis of Upgrading vs. Replacing Construction Equipment. Journal of Construction Economics, 28(1), 45-60.