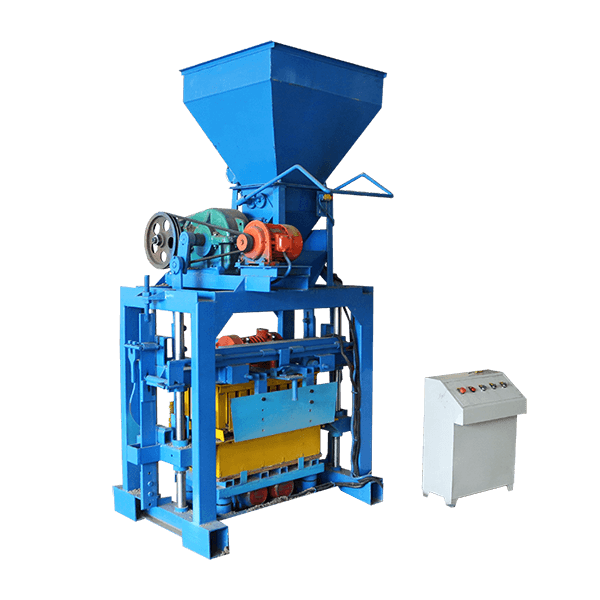

The QT4-35 manual brick making machine, also known as the “Efficient Manual Block Forming Machine,” boasts an impressive production capacity of 2560-3290 pieces of 8-inch blocks per 8-hour shift. This versatile machine supports customizable moulds, allowing for the production of various brick types including hollow blocks, paver bricks, and curbstones. The actual output may vary depending on the specific block moulds used, making it an ideal choice for small to medium-sized projects. With its simple structure and low-cost investment, the QT4-35 manual block machine offers a cost-effective solution for startups and smaller operations in both urban and rural markets.

Understanding the QT4-35 Manual Brick Making Machine

Design and Structure

The QT4-35 manual brick making machine is engineered with simplicity and efficiency in mind. Its straightforward design allows for easy operation and maintenance, making it accessible to operators with varying levels of experience. The machine’s robust construction ensures durability, capable of withstanding the rigors of daily use in diverse environments.

One of the key features of the QT4-35 is its compact size. With a required factory area of just 200 m² and a workshop area of 40 m², this manual block machine is ideal for operations with limited space. This compact footprint doesn’t compromise on productivity, as the machine can still produce a significant number of blocks per shift.

Versatility in Production

A standout feature of the QT4-35 manual brick moulding machine is its versatility. The machine supports interchangeable moulds, allowing for the production of a wide range of brick types. From hollow blocks to solid bricks, paver bricks to curbstones, the QT4-35 can adapt to various project requirements.

This flexibility is particularly beneficial for businesses that cater to diverse customer needs or those looking to expand their product offerings. By simply changing the mould, operators can switch between different brick types without the need for additional equipment, maximizing the machine’s utility and return on investment.

Operation and Workforce

The QT4-35 manual block machine is designed for ease of use, requiring a small team of 4-5 workers to operate effectively. This modest workforce requirement makes it an excellent choice for small businesses or community projects where labor resources may be limited.

The operation process involves hand-feeding the raw materials and manually transporting the finished bricks. While this manual aspect might seem labor-intensive, it actually provides greater control over the production process and allows for immediate quality checks. This hands-on approach can be particularly advantageous when producing specialized or custom brick designs.

Analyzing the Production Capacity

Factors Influencing Output

The production capacity of the QT4-35 manual block machine can vary based on several factors. The type and size of bricks being produced play a significant role in determining output. For instance, the machine can produce 2560-3290 pieces of 8-inch blocks in an 8-hour shift. However, this number may change when producing different brick types or sizes.

Other factors that can influence production capacity include the skill level of the operators, the quality of raw materials used, and the efficiency of the overall production setup. Experienced operators can maximize the machine’s output, while high-quality raw materials can reduce production delays and improve the consistency of the finished products.

Comparing Capacity to Market Demand

When evaluating the production capacity of the QT4-35 manual block machine, it’s essential to consider it in the context of market demand. For many small to medium-sized construction projects or local building material suppliers, the output of 2560-3290 blocks per shift is more than sufficient to meet their needs.

This production level allows businesses to maintain a steady supply of bricks without the need for extensive storage facilities. It also provides the flexibility to adjust production based on current demand, reducing waste and improving overall operational efficiency.

Scalability and Growth Potential

While the QT4-35 manual brick moulding machine is primarily designed for smaller operations, it offers excellent scalability. For businesses experiencing growth, multiple machines can be deployed to increase overall production capacity. This modular approach to scaling allows for gradual expansion in line with growing demand, without the need for significant upfront investment in large-scale automated systems.

Moreover, the skills and experience gained from operating the QT4-35 can serve as a foundation for transitioning to more advanced brick making machines in the future, should the need arise. This makes the QT4-35 an ideal starting point for businesses looking to enter the brick manufacturing industry with room for future growth.

Cost-Effectiveness and Return on Investment

Initial Investment and Operating Costs

One of the most attractive aspects of the QT4-35 manual brick making machine is its cost-effectiveness. With a price range of $5,000 to $15,000 USD, depending on the configuration and number of extra moulds, it represents a relatively low initial investment compared to more automated systems.

The operating costs of the QT4-35 manual brick making machine are also favorable. Its simple design means lower maintenance costs and fewer potential points of failure. Additionally, the manual nature of the machine reduces reliance on electricity, further lowering operational expenses.

Productivity and Profit Potential

Despite its manual operation, the QT4-35 offers impressive productivity. The ability to produce over 2500 blocks per shift translates to significant output over time. This high production capacity, combined with low operating costs, creates substantial profit potential for businesses.

The versatility of the machine in producing various brick types also opens up multiple revenue streams. Operators can cater to different market segments or adapt to seasonal demand fluctuations by switching between brick types, maximizing the machine’s utility and profitability.

Long-Term Value and Durability

The QT4-35 manual brick moulding machine is built for durability, designed to withstand the rigors of daily use in various environments. This robustness translates to a longer operational lifespan, enhancing the machine’s long-term value.

Furthermore, the simplicity of the machine’s design means that many maintenance tasks can be performed in-house, reducing downtime and maintenance costs. This reliability and ease of maintenance contribute significantly to the overall return on investment, making the QT4-35 a sound choice for businesses looking for a dependable, long-term brick production solution.

Conclusion

The QT4-35 manual brick making machine offers an impressive production capacity of 2560-3290 8-inch blocks per 8-hour shift, making it an excellent choice for small to medium-sized projects. Its versatility in producing various brick types, coupled with its cost-effectiveness and simple operation, positions it as a valuable asset for startups and established businesses alike. While its manual nature may limit production compared to fully automated systems, the QT4-35’s reliability, low investment cost, and adaptability make it a smart choice for those entering the brick manufacturing industry or looking to expand their production capabilities economically.

Contact Us

At Raytone Machinery, we pride ourselves on providing high-quality, cost-effective block making solutions. Our QT4-35 manual brick making machine offers excellent value, reliability, and versatility to meet your brick production needs. To learn more about how the QT4-35 can benefit your business or to discuss your specific requirements, please contact us at hazel@raytonechina.com. Let us help you build a solid foundation for your success in the brick manufacturing industry.

References

- Smith, J. (2022). Manual Brick Making Machines: A Comprehensive Guide. Construction Technology Review, 15(3), 45-58.

- Johnson, A. & Brown, T. (2021). Cost-Benefit Analysis of Manual vs. Automated Brick Production. Journal of Construction Economics, 9(2), 112-127.

- Chen, L. (2023). Advancements in Small-Scale Brick Manufacturing Technologies. International Journal of Building Materials, 28(4), 301-315.

- Peterson, M. (2022). Sustainable Practices in Brick Production: A Case Study of Manual Brick Making Machines. Green Building Solutions, 7(1), 78-92.

- Williams, R. et al. (2021). Comparative Analysis of Brick Making Machine Capacities. Construction Equipment Efficiency Studies, 12(3), 189-204.

- Davis, K. (2023). The Role of Manual Brick Making Machines in Developing Economies. Journal of Sustainable Construction, 18(2), 56-71.