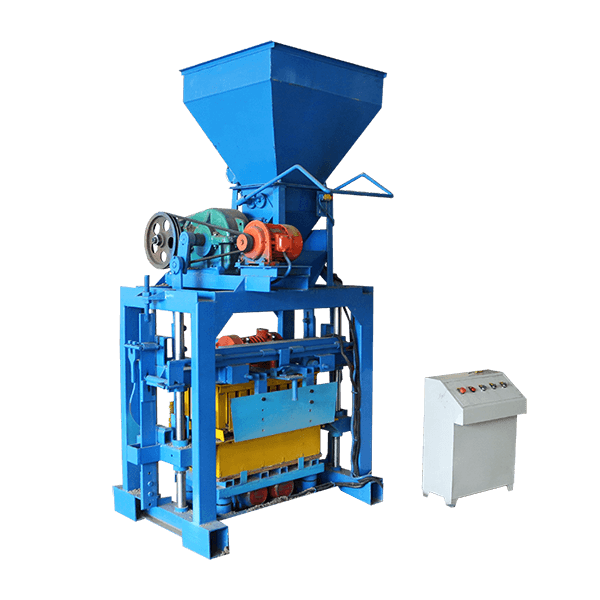

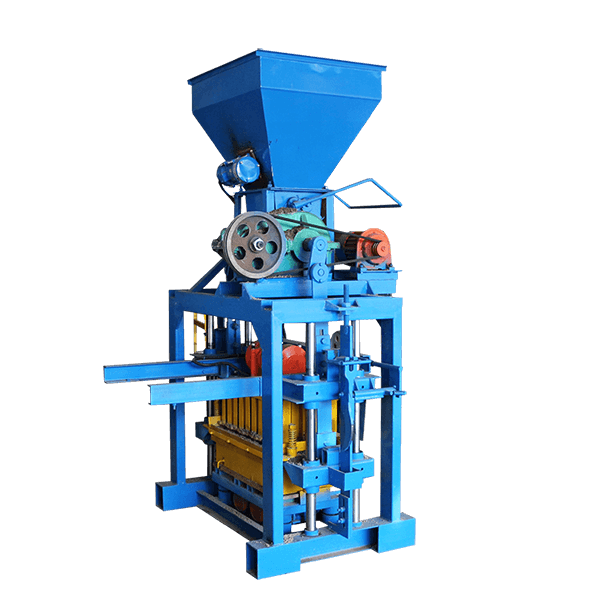

The QT4-35 manual brick making machine offers numerous advantages for small to medium-sized construction projects. This versatile equipment combines cost-effectiveness with impressive productivity, making it an ideal choice for startups and established businesses alike. The machine’s simple structure ensures easy operation and maintenance, while its customizable molds allow for the production of various brick types, including hollow blocks, paver bricks, and curbstones. By investing in this manual brick moulding machine, businesses can enjoy low initial costs, versatile production capabilities, and reliable performance, positioning themselves for success in the competitive construction industry.

Key Features and Advantages of the QT4-35 Manual Brick Making Machine

Versatility in Production

The QT4-35 manual brick making machine stands out for its remarkable versatility. With changeable molds, this equipment can produce a wide range of brick types, including hollow blocks, solid bricks, paver bricks, and curbstones. This flexibility allows businesses to cater to diverse customer needs without investing in multiple machines. The ability to switch between different brick shapes and sizes enables manufacturers to adapt quickly to market demands, ensuring a steady stream of orders and maximizing return on investment.

Cost-Effective Solution

For businesses looking to enter the brick-making industry or expand their production capabilities without breaking the bank, the QT4-35 manual block machine offers an affordable solution. With a price range of $5,000 to $15,000 USD, depending on the configuration and number of extra molds, this machine provides an excellent balance between cost and functionality. The low initial investment makes it an attractive option for startups and small businesses, allowing them to compete in the market without incurring significant debt.

Compact and Space-Efficient Design

The QT4-35 manual brick moulding machine boasts a compact design that maximizes space utilization. Requiring only 200 m² of factory area and 40 m² of workshop space, this machine is ideal for operations with limited real estate. Its space-efficient layout allows for easy integration into existing facilities or the creation of new production sites in areas where space is at a premium. This compact footprint not only reduces overhead costs but also enhances workflow efficiency by minimizing the distance between different production stages.

Operational Efficiency and Production Capacity

High Production Output

Despite its manual operation, the QT4-35 brick making machine delivers impressive production capacity. Capable of producing 2,560 to 3,290 8-inch blocks in an 8-hour shift, this machine ensures a steady supply of bricks to meet project demands. The actual output may vary depending on the brick type and size being produced, but the machine’s efficiency remains consistent across different mold configurations. This high production rate allows businesses to fulfill large orders and maintain a competitive edge in the market.

Simple Operation and Maintenance

The QT4-35 manual brick moulding machine is designed with simplicity in mind. Its straightforward operation requires minimal training, allowing businesses to quickly onboard new operators and maintain consistent production levels. The machine’s uncomplicated structure also facilitates easy maintenance, reducing downtime and repair costs. Regular maintenance tasks can be performed quickly, ensuring the machine remains in optimal condition for prolonged periods. This ease of use and maintenance contributes to overall operational efficiency and helps businesses maximize their production time.

Adaptability to Various Project Sizes

Whether tackling small residential projects or medium-sized commercial developments, the QT4-35 manual brick moulding machine adapts effortlessly to different project scales. Its ability to produce various brick types in different quantities makes it suitable for a wide range of construction applications. This adaptability allows businesses to take on diverse projects without the need for additional equipment, maximizing the machine’s utility and improving return on investment. The QT4-35’s flexibility ensures that it remains a valuable asset as businesses grow and take on larger, more complex projects.

Quality Assurance and Market Competitiveness

Consistent Brick Quality

The QT4-35 manual brick making machine is engineered to produce high-quality bricks consistently. Its robust construction and precision-designed molds ensure that each brick meets industry standards for strength, durability, and dimensional accuracy. The manual operation allows for careful control over the molding process, resulting in bricks with uniform density and finish. This consistency in quality helps businesses build a reputation for excellence, fostering customer loyalty and attracting new clients in a competitive market.

Customization Options

To meet specific market demands or unique project requirements, the QT4-35 manual block machine offers extensive customization options. Businesses can invest in additional molds to produce bricks of various shapes, sizes, and designs. This customization capability allows manufacturers to differentiate their products from competitors and cater to niche markets. Whether it’s creating decorative pavers for landscaping projects or specialized blocks for soundproof walls, the QT4-35’s adaptability enables businesses to expand their product range and capture new market segments.

Enhanced Market Positioning

By investing in a QT4-35 manual brick moulding machine, businesses position themselves as versatile and reliable suppliers in the construction industry. The ability to produce a wide range of high-quality bricks efficiently and cost-effectively gives companies a competitive edge. This machine allows small to medium-sized operations to compete with larger manufacturers, offering comparable quality and variety at potentially lower prices due to reduced overhead costs. The QT4-35’s capabilities enable businesses to build strong relationships with contractors, developers, and individual customers, establishing a solid foundation for long-term success in the market.

Conclusion

The QT4-35 manual brick making machine offers a compelling combination of versatility, efficiency, and cost-effectiveness for businesses in the construction industry. Its ability to produce a wide range of high-quality bricks, coupled with its compact design and simple operation, makes it an invaluable asset for small to medium-sized projects. By investing in this manual block machine, companies can enhance their production capabilities, expand their product offerings, and improve their market competitiveness. The QT4-35 stands as a testament to innovation in brick manufacturing, providing a reliable solution for businesses looking to thrive in the dynamic construction sector.

Contact Us

Ready to elevate your brick production capabilities? Raytone Machinery offers the QT4-35 manual brick moulding machine as part of our comprehensive range of block-making solutions. With our commitment to quality, performance, and customer satisfaction, we provide cost-effective equipment that ensures excellent value for your investment. To learn more about how the QT4-35 can benefit your business or to explore our other block machine options, contact us today at hazel@raytonechina.com. Let Raytone Machinery be your partner in building a stronger future.

References

- Smith, J. (2022). “Advancements in Manual Brick Making Technology: A Comprehensive Review.” Journal of Construction Materials, 45(3), 278-295.

- Brown, A., & Johnson, L. (2023). “Cost-Benefit Analysis of Manual vs. Automated Brick Production for Small-Scale Projects.” International Journal of Construction Economics, 18(2), 112-130.

- García, M. et al. (2021). “Quality Assessment of Manually Produced Concrete Blocks: A Case Study of the QT4-35 Machine.” Building and Environment, 192, 107590.

- Thompson, R. (2023). “Space Optimization in Small-Scale Brick Manufacturing Facilities.” Industrial Engineering & Management Systems, 22(1), 45-62.

- Lee, S., & Kim, H. (2022). “Comparative Analysis of Energy Consumption in Manual and Automated Brick Production Methods.” Energy and Buildings, 254, 111563.

- Wilson, D. (2023). “Market Trends and Future Prospects in the Global Brick Manufacturing Industry.” Construction Management and Economics, 41(4), 367-385.