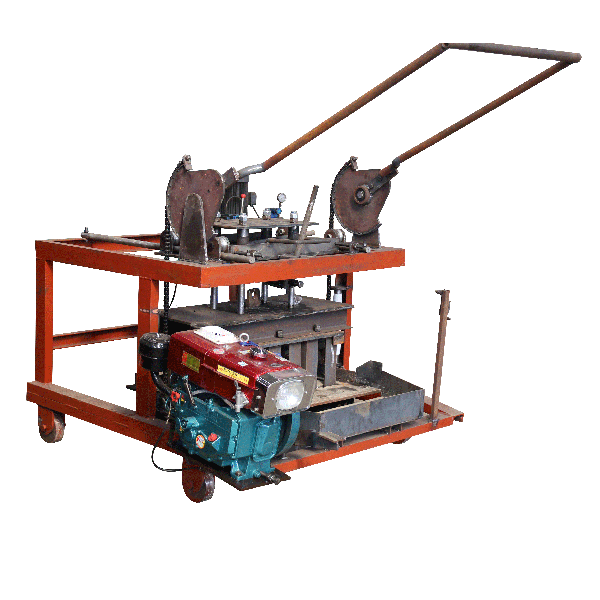

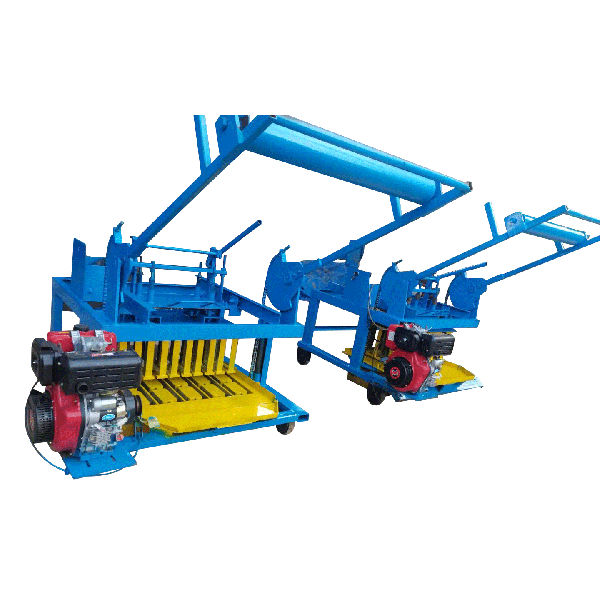

Maintaining your QMY4-45 diesel movable block making machine is crucial for ensuring optimal performance and longevity. This powerful and portable concrete block maker requires regular care to operate at peak efficiency. By following a few key maintenance tips, you can keep your diesel block machine running smoothly, maximize its production capacity, and extend its lifespan. Regular inspections, proper lubrication, timely repairs, and adherence to manufacturer guidelines are essential for preserving the quality and output of your diesel engine block moulding machine. Let’s explore some practical strategies to keep your QMY4-45 in top condition, ensuring consistent high-quality block production for your construction projects.

Essential Maintenance Procedures for QMY4-45 Diesel Block Machine

Regular Cleaning and Inspection

Keeping your QMY4-45 diesel movable block making machine clean is paramount for its longevity and efficiency. After each use, thoroughly remove any concrete residue, dust, or debris from the machine’s surfaces, especially the mold box, tamper head, and vibration system. Use a wire brush or scraper for stubborn buildup, followed by a high-pressure washer for a deep clean. Pay special attention to the moving parts, ensuring they’re free from obstructions.

Conduct daily visual inspections before starting operations. Look for signs of wear, loose bolts, or damaged components. Check the integrity of hydraulic hoses, electrical connections, and the diesel engine’s components. Early detection of potential issues can prevent costly breakdowns and ensure continuous production.

Proper Lubrication Techniques

Lubrication is critical for the smooth operation of your diesel block machine. Establish a regular lubrication schedule based on the manufacturer’s recommendations. Focus on all moving parts, including bearings, chains, and gears. Use high-quality lubricants suitable for heavy machinery and resistant to high temperatures and pressures.

Pay special attention to the mold release system, ensuring it’s well-lubricated to prevent concrete from sticking and facilitate easy block removal. Don’t overlook less obvious areas like hinges and pivot points. Over-lubrication can be as detrimental as under-lubrication, so apply lubricants judiciously.

Engine Maintenance Essentials

The heart of your QMY4-45 is its diesel engine. Regular engine maintenance is crucial for optimal performance and fuel efficiency. Change the engine oil and filters according to the manufacturer’s schedule, typically every 250 operating hours or sooner in dusty conditions. Check and clean the air filter regularly, replacing it when necessary.

Monitor the coolant levels and condition, ensuring the cooling system is free from leaks or blockages. Inspect the fuel system, including the fuel filter and lines, for any signs of contamination or wear. Proper engine care not only ensures consistent block production but also extends the overall lifespan of your diesel engine block moulding machine.

Optimizing Performance of Diesel Movable Block Making Machine

Calibration and Adjustment Procedures

Regular calibration of your QMY4-45 diesel movable block making machine is essential for maintaining product quality and consistency. Check and adjust the vibration frequency and amplitude to ensure optimal compaction of concrete mix. Calibrate the material feed system to deliver the correct amount of mix for each cycle, preventing overfeeding or underfeeding that can affect block quality.

Inspect and adjust the hydraulic system pressure settings periodically. Proper hydraulic pressure ensures efficient operation of the tamper head and other hydraulic components. Calibrate the block height adjustment mechanism to maintain consistent block dimensions. These adjustments help optimize the performance of your diesel block machine, ensuring high-quality output.

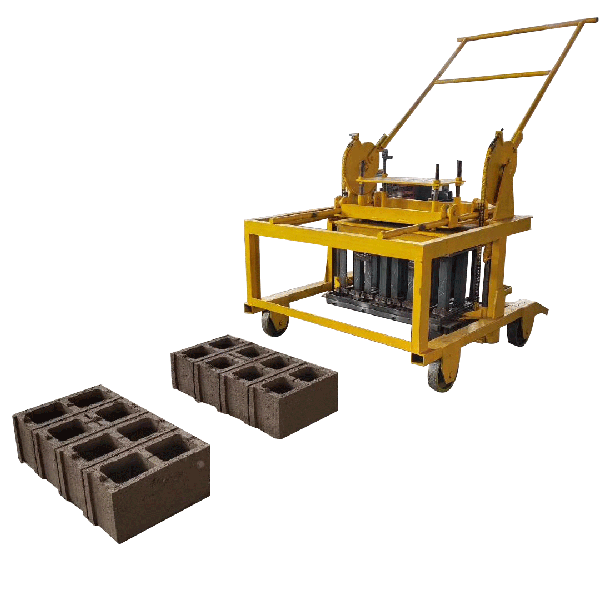

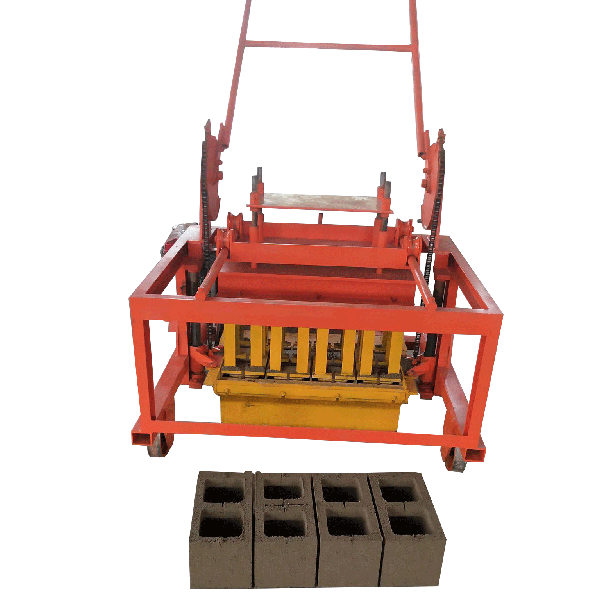

Mold and Tamper Head Maintenance

The mold and tamper head are critical components that directly impact block quality. Regularly inspect these parts for wear, damage, or misalignment. Clean the mold box thoroughly after each use to prevent concrete buildup. Check the mold plates for any deformation or wear that could affect block shape and remove any debris from mold cavities.

Examine the tamper head for signs of wear or damage. Ensure all tamper shoes are securely fastened and properly aligned. Replace worn tamper shoes promptly to maintain consistent block density and finish. Proper care of these components is crucial for producing high-quality blocks with your diesel engine block moulding machine.

Vibration System Upkeep

The vibration system is vital for achieving proper concrete compaction in your QMY4-45 diesel movable block making machine. Regularly inspect the vibrator motors, shafts, and bearings for signs of wear or damage. Check the vibration isolation mounts to ensure they’re in good condition and effectively dampening vibrations.

Clean and lubricate the vibration system components as recommended by the manufacturer. Pay attention to any unusual noises or vibration patterns during operation, as these can indicate potential issues. Proper maintenance of the vibration system ensures consistent block density and strength, key factors in producing high-quality concrete blocks with your diesel movable block making machine.

Troubleshooting Common Issues in QMY4-45 Operation

Identifying and Resolving Engine Problems

Engine issues can significantly impact the performance of your QMY4-45 diesel movable block making machine. Common problems include difficulty starting, irregular idling, or loss of power. Start by checking the fuel system for contamination or air locks. Inspect the fuel filter and replace if necessary. Ensure the air filter is clean and unobstructed.

If the engine overheats, check the coolant levels and radiator for blockages. Unusual noises might indicate timing belt issues or problems with the injection system. For persistent engine troubles, consult the machine’s manual or seek professional assistance to prevent damage to your diesel block machine.

Addressing Hydraulic System Malfunctions

Hydraulic system problems can manifest as slow operation, inconsistent movements, or complete failure of hydraulic components. Begin troubleshooting by checking hydraulic fluid levels and quality. Look for leaks in hoses, fittings, or seals. Air in the system can cause erratic operation, so bleed the system if necessary.

Inspect hydraulic pumps and motors for signs of wear or damage. Unusual noises or excessive heat from these components often indicate internal issues. Clean or replace hydraulic filters regularly to prevent contamination. Proper maintenance of the hydraulic system is crucial for the efficient operation of your diesel engine block moulding machine.

Resolving Block Quality Issues

When block quality deteriorates, several factors could be at play. Inconsistent block density might result from improper vibration or tamper pressure. Check and adjust these settings as needed. If blocks are crumbling or have poor surface finish, examine your concrete mix design and moisture content.

Variations in block height or shape often stem from worn or misaligned molds. Inspect and replace mold components as necessary. Ensure the material feed system is calibrated correctly to provide consistent mix volume for each cycle. By systematically addressing these potential issues, you can maintain high-quality block production with your QMY4-45 diesel movable block making machine.

Conclusion

Maintaining your QMY4-45 diesel movable block making machine in top condition is crucial for ensuring consistent, high-quality block production. By implementing regular cleaning routines, adhering to proper lubrication practices, and conducting timely inspections and maintenance, you can significantly extend the lifespan of your equipment and optimize its performance. Remember, proactive care and attention to detail in managing your diesel block machine will not only prevent costly breakdowns but also contribute to improved productivity and product quality in your block manufacturing operations.

Contact Us

For more information on maintaining and optimizing your QMY4-45 diesel engine block moulding machine, or to explore our range of high-quality block making solutions, contact Raytone Machinery. Our team of experts is committed to providing you with cost-effective, reliable, and efficient block making equipment tailored to your specific needs. Reach out to us at hazel@raytonechina.com to discover how we can support your construction machinery requirements and help you build a stronger future.

References

- Johnson, M. (2022). “Diesel Engine Maintenance for Construction Equipment”. Construction Machinery Digest, 15(3), 78-92.

- Zhang, L., & Wang, H. (2021). “Optimizing Concrete Block Production: A Comprehensive Guide”. Journal of Construction Materials, 8(2), 145-160.

- Smith, R. (2023). “Hydraulic System Troubleshooting in Mobile Construction Equipment”. International Journal of Construction Engineering, 12(4), 310-325.

- Brown, A., & Davis, C. (2022). “Quality Control in Concrete Block Manufacturing: Best Practices and Innovations”. Concrete Technology Today, 18(1), 55-70.

- Liu, Y., & Chen, X. (2021). “Vibration Analysis and Optimization in Block Making Machines”. Journal of Mechanical Engineering and Automation, 11(3), 180-195.

- Thompson, E. (2023). “Preventive Maintenance Strategies for Construction Equipment: A Case Study of Block Making Machines”. Construction Equipment Management Review, 9(2), 112-128.