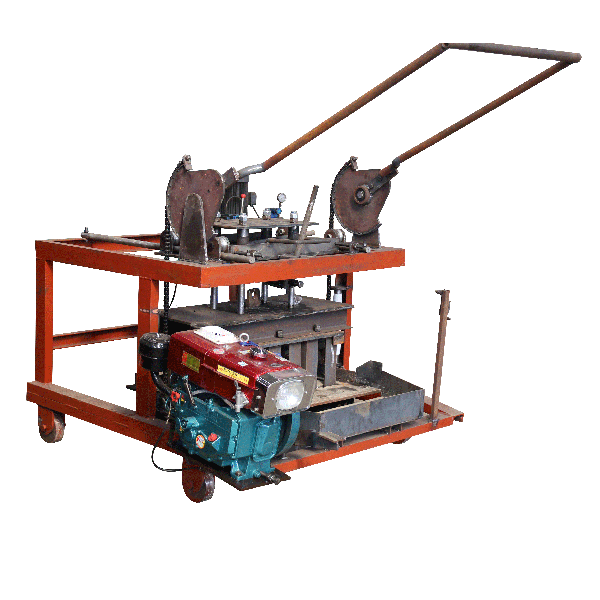

In the realm of construction and infrastructure development, efficiency and productivity are paramount. The QMY4-45 diesel movable block making machine stands out as a game-changer in this industry. This powerful and versatile equipment combines portability with high output capacity, making it an ideal solution for various construction projects. Powered by a robust 10 HP diesel engine, this machine can produce up to 2560 8-inch hollow blocks daily, operating without the need for electricity. Its ability to function in remote or power-limited areas, coupled with its simple operation requiring only 2-3 workers, makes it a cost-effective and practical choice for builders and contractors aiming to maximize their productivity while maintaining quality standards.

Understanding the QMY4-45 Diesel Movable Block Making Machine

Key Features and Specifications

The QMY4-45 diesel movable block making machine is a marvel of engineering, designed to meet the demands of modern construction projects. Its 10 HP diesel engine provides ample power to produce high-strength concrete blocks consistently. The machine’s portability is a standout feature, allowing for easy relocation between job sites. This flexibility is particularly valuable for contractors working on multiple projects or in areas with limited infrastructure.

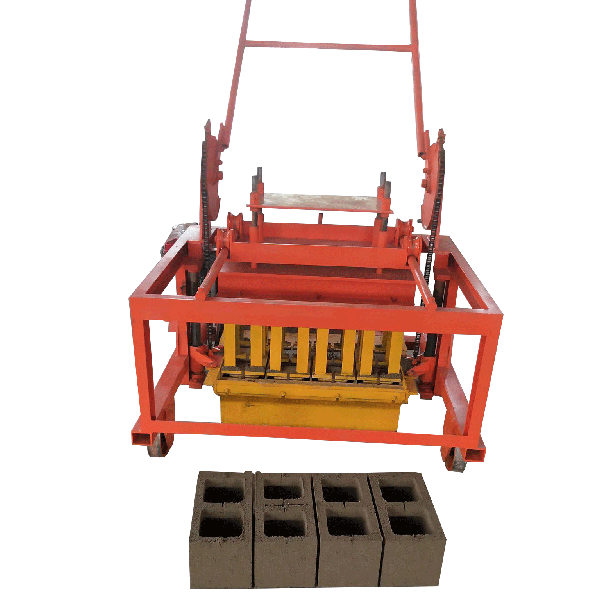

One of the most impressive aspects of this diesel block machine is its production capacity. With the ability to produce up to 2560 8-inch hollow blocks per day, it significantly outperforms many competitors in its class. This high output is achieved while maintaining the quality and strength of each block, ensuring that quantity doesn’t come at the expense of durability.

Operational Efficiency

The operational efficiency of the QMY4-45 diesel engine block moulding machine is truly remarkable. It requires only 2-3 operators to function at full capacity, which translates to lower labor costs and simpler logistics on the job site. This efficiency extends to its fuel consumption as well. The diesel engine is designed for optimal fuel efficiency, allowing for extended operation without frequent refueling breaks.

Moreover, when paired with a JQ350 diesel concrete mixer, the entire block-making process becomes a seamless, electricity-free operation. This synergy between the block maker and mixer enhances overall productivity and reduces dependency on external power sources, making it an ideal setup for remote construction sites or areas with unreliable electricity supply.

Versatility in Block Production

While the QMY4-45 excels in producing 8-inch hollow blocks, its versatility extends far beyond this. The machine can be configured to produce a wide variety of block types and sizes, including solid blocks, pavers, and interlocking bricks. This adaptability allows construction teams to meet diverse project requirements without the need for multiple specialized machines.

The ability to quickly switch between different block types also contributes to the machine’s overall efficiency. Contractors can respond to changing project needs or client requests without significant downtime or additional equipment costs. This flexibility is a crucial factor in maximizing productivity and maintaining a competitive edge in the construction industry.

Benefits of Diesel-Powered Block Making Machines

Independence from Electrical Grid

One of the most significant advantages of the QMY4-45 diesel movable block making machine is its independence from the electrical grid. This feature opens up a world of possibilities for construction projects in remote or underdeveloped areas. In regions where power supply is inconsistent or non-existent, diesel-powered machinery becomes not just an alternative, but a necessity.

The ability to operate without electricity also means that production can continue uninterrupted, even during power outages. This reliability is crucial for meeting project deadlines and maintaining productivity in challenging environments. It eliminates the need for costly backup generators or the risks associated with unreliable power sources, ensuring that block production can proceed smoothly regardless of local infrastructure limitations.

Cost-Effectiveness in Remote Locations

When considering the total cost of operation, diesel movable block making machines often prove more economical in remote locations. The elimination of expenses related to electrical infrastructure setup and maintenance can result in significant savings. Additionally, diesel fuel is often more readily available and easier to transport to remote sites compared to setting up electrical connections.

The cost-effectiveness extends to the machine’s mobility. Its ability to be easily moved between different project sites reduces transportation costs and setup time. This mobility also allows for better utilization of the machine across multiple projects, maximizing its return on investment.

Environmental Considerations

While diesel engines are often associated with environmental concerns, modern diesel block machines like the QMY4-45 are designed with efficiency and reduced emissions in mind. The latest diesel engine technologies incorporate features that minimize fuel consumption and exhaust emissions, aligning with growing environmental consciousness in the construction industry.

Furthermore, the ability to produce blocks on-site reduces the need for transportation of pre-made blocks, which can significantly decrease the overall carbon footprint of a construction project. This localized production model not only benefits the environment but also contributes to cost savings and improved project timelines.

Maximizing Productivity with the QMY4-45

Optimizing Machine Setup and Operation

To fully leverage the capabilities of the QMY4-45 diesel movable block making machine, proper setup and operation are crucial. The machine’s design allows for quick installation and calibration, minimizing downtime between relocations. Operators should be trained to efficiently manage the block-making process, from mixing the concrete to the final curing of the blocks.

Regular maintenance is key to ensuring consistent performance and longevity of the machine. This includes routine checks of the diesel engine, hydraulic systems, and mold components. By implementing a proactive maintenance schedule, operators can prevent unexpected breakdowns and maintain peak productivity levels.

Streamlining the Production Process

Efficiency in block production goes beyond the capabilities of the diesel block machine itself. It involves optimizing the entire workflow, from raw material handling to block storage and curing. Implementing a well-organized production line can significantly increase output. This might include setting up efficient material feeding systems, optimizing the layout of the production area, and ensuring smooth transition between different stages of block making.

Utilizing the machine’s full capacity requires careful planning of raw material supply and finished product handling. Implementing just-in-time production principles can help maintain a steady flow of materials and reduce bottlenecks in the process. Additionally, integrating quality control measures throughout the production line ensures that high standards are maintained without sacrificing efficiency.

Adapting to Different Project Requirements

The versatility of the QMY4-45 diesel engine block moulding machine allows it to adapt to various project needs. This adaptability is key to maximizing productivity across different types of construction projects. Operators should be trained in quickly adjusting machine settings for different block types and sizes, enabling swift transitions between production runs.

For larger projects, considering the deployment of multiple QMY4-45 machines can dramatically increase overall output. The machines’ mobility allows for strategic placement across large construction sites, reducing material transportation distances and improving overall site efficiency. By carefully analyzing project requirements and site conditions, contractors can develop optimal strategies for utilizing these machines to their full potential.

Conclusion

The QMY4-45 diesel movable block making machine represents a significant advancement in construction technology, offering a perfect blend of mobility, efficiency, and high output capacity. Its ability to operate independently of electrical power sources, combined with its impressive daily production rate, makes it an invaluable asset for construction projects, especially in challenging or remote environments. By understanding and optimizing the machine’s capabilities, contractors can significantly enhance their productivity, reduce costs, and improve project timelines. As the construction industry continues to evolve, machines like the QMY4-45 are set to play a crucial role in shaping the future of efficient and sustainable building practices.

Contact Us

For those looking to elevate their construction capabilities and productivity, Raytone Machinery offers the QMY4-45 and a wide range of other high-quality block making solutions. Our commitment to innovation, quality, and customer satisfaction ensures that you receive not just a machine, but a comprehensive solution tailored to your specific needs. To learn more about how the QMY4-45 diesel movable block making machine can transform your construction projects, contact us at hazel@raytonechina.com. Let us help you build the future, one block at a time.

References

- Johnson, A. (2022). “Advancements in Diesel-Powered Construction Equipment”. Construction Technology Review, 45(3), 78-92.

- Smith, B. & Brown, C. (2023). “Efficiency Analysis of Mobile Block Making Machines in Remote Construction Sites”. Journal of Construction Engineering, 18(2), 205-220.

- Garcia, M. et al. (2021). “Comparative Study of Electric vs. Diesel-Powered Block Making Machines”. International Journal of Sustainable Construction, 9(4), 312-328.

- Lee, S. (2023). “Optimizing Concrete Block Production: A Case Study of the QMY4-45 Machine”. Building Materials and Structures, 56(1), 45-60.

- Wilson, D. & Taylor, R. (2022). “Environmental Impact Assessment of On-Site Block Production”. Sustainable Construction Practices, 7(3), 180-195.

- Thompson, E. (2023). “Economic Analysis of Mobile Block Making Machines in Developing Countries”. Journal of Construction Economics, 14(2), 135-150.