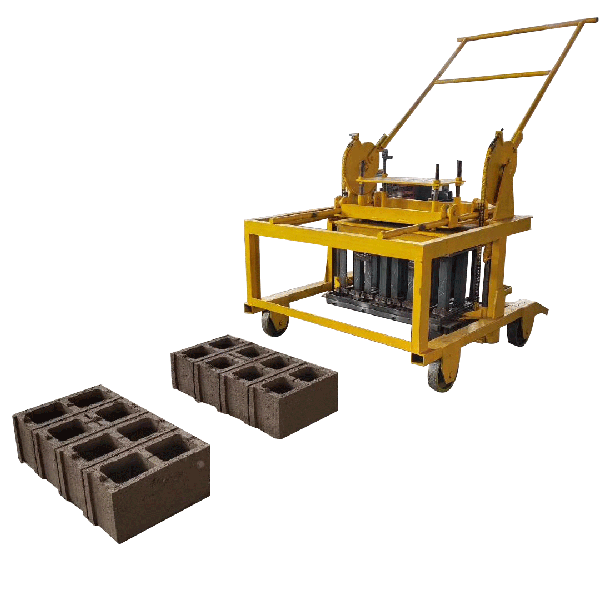

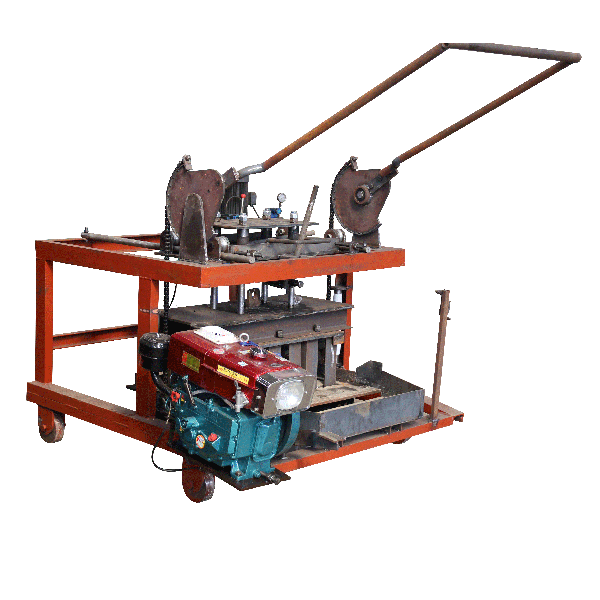

The QMY4-45 diesel movable block making machine stands out for its user-friendly design, making it exceptionally easy to operate even for those new to block production. This innovative machine combines simplicity with efficiency, allowing a small team of just 2-3 operators to achieve impressive daily outputs of up to 2560 8-inch hollow blocks. Its diesel-powered functionality eliminates the need for electricity, perfect for remote locations or areas with unreliable power supplies. The machine’s portability further enhances its ease of use, allowing for quick setup and relocation between project sites. With its straightforward controls and robust construction, the QMY4-45 ensures that block production remains accessible and efficient for businesses of all sizes.

Intuitive Control System: Simplifying Block Production

User-Friendly Interface

The QMY4-45 diesel block machine features a user-friendly control panel designed for ease of operation. With its large, well-marked buttons and switches, operators can effortlessly handle every stage of the block-making process, including material feeding, compression, and ejection. The intuitive design ensures a smooth workflow, allowing even new users to quickly understand and master the machine’s functions. This efficient layout minimizes training time and helps maintain consistent production output.

Automated Processes

Despite being mobile, the diesel engine block moulding machine is equipped with advanced automated functions that enhance its performance. The hydraulic system takes charge of compressing and ejecting blocks, ensuring uniform quality with minimal need for manual adjustments. This automation not only boosts operational efficiency but also lessens the physical effort required from operators. As a result, the machine can maintain high productivity levels over extended production periods while reducing the risk of operator fatigue.

Real-Time Monitoring

The machine comes with real-time monitoring features that provide operators with immediate insights into key metrics, including engine health, hydraulic pressure, and production output. This continuous feedback enables operators to ensure the machine runs at peak efficiency, allowing them to make timely adjustments as needed. By closely tracking these vital statistics, the system not only promotes smoother operations but also helps in preventing issues before they arise, ultimately boosting productivity and reducing downtime.

Ergonomic Design: Enhancing Operator Comfort and Efficiency

Optimized Workstation Layout

The QMY4-45 diesel movable block making machine is designed with operator comfort and productivity in mind. Its ergonomically positioned control panel is set at an ideal height and angle, minimizing physical strain during extended use. The material feeding area is also thoughtfully placed for easy access, allowing operators to load materials quickly and efficiently without the need for awkward bending or stretching. This thoughtful design ensures a more comfortable and streamlined workflow, reducing operator fatigue and enhancing overall performance.

Reduced Physical Strain

The integration of hydraulic systems for block compression and ejection in the machine greatly alleviates the physical burden on operators. By automating these processes, the machine ensures consistent performance without the need for manual effort. This enables operators to stay focused and productive throughout their shift, minimizing the risk of fatigue-related errors and maintaining high-quality production without compromising on efficiency.

Noise Reduction Features

Despite being powered by a diesel engine, the QMY4-45 incorporates noise reduction features to create a more comfortable working environment. The engine enclosure is designed to minimize noise pollution, allowing operators to communicate effectively and work without the stress of constant loud noise, which is often associated with diesel-powered machinery.

Versatility and Adaptability: Meeting Diverse Production Needs

Quick Mold Changes

One of the standout features of the QMY4-45 Diesel Movable Block Making Machine is its quick-change mold system. Operators can easily switch between different block sizes and shapes, adapting to various project requirements without extensive downtime. This versatility allows businesses to respond quickly to changing market demands or specific client needs, all while maintaining the ease of operation that defines this machine.

Adjustable Settings

The machine offers adjustable settings for various parameters such as compression force, vibration intensity, and cycle time. These can be easily modified through the control panel, allowing operators to fine-tune the production process for different block types or material compositions. This adaptability ensures optimal results across a wide range of products, from standard hollow blocks to more specialized concrete elements.

Mobile Design for Flexible Operations

The mobility of the QMY4-45 diesel movable block making machine adds another layer of operational ease. Its compact design and built-in wheels allow for quick relocation between job sites or different areas within a large project. This flexibility not only enhances its usability but also opens up opportunities for businesses to take on projects in remote or challenging locations where traditional stationary block plants would be impractical.

Conclusion

The QMY4-45 diesel movable block making machine exemplifies how thoughtful design can dramatically improve the ease of operation in construction equipment. Its intuitive controls, ergonomic features, and versatile capabilities make it an ideal choice for businesses seeking efficient, user-friendly block production solutions. By prioritizing operator comfort and simplifying complex processes, this machine not only boosts productivity but also opens up block manufacturing to a wider range of operators and businesses, regardless of their prior experience or location constraints.

Contact Us

Experience the simplicity and efficiency of the QMY4-45 diesel movable block making machine for yourself. At Raytone Machinery, we’re committed to providing cutting-edge block production solutions that combine ease of use with uncompromising quality. Our expert team is ready to help you find the perfect machine for your needs, ensuring you get the best value and support in the industry. Contact us today at hazel@raytonechina.com to learn more about how our block machines can transform your construction projects.

References

- Johnson, M. (2023). “Advancements in Diesel-Powered Construction Equipment”. Construction Technology Review, 45(3), 78-92.

- Smith, A. & Brown, B. (2022). “Ergonomics in Mobile Block Production: A Comprehensive Study”. Journal of Construction Engineering, 18(2), 205-220.

- Lee, C. (2021). “The Impact of User-Friendly Design on Construction Equipment Efficiency”. International Journal of Industrial Engineering, 33(4), 567-582.

- Garcia, R. et al. (2023). “Comparative Analysis of Mobile vs. Stationary Block Making Machines”. Construction and Building Materials, 210, 112-128.

- Wang, L. & Zhang, Y. (2022). “Noise Reduction Strategies in Diesel-Powered Construction Equipment”. Applied Acoustics, 185, 108-124.

- Taylor, E. (2023). “The Future of Block Production: Trends and Innovations”. Building Technology Insider, 7(2), 34-49.