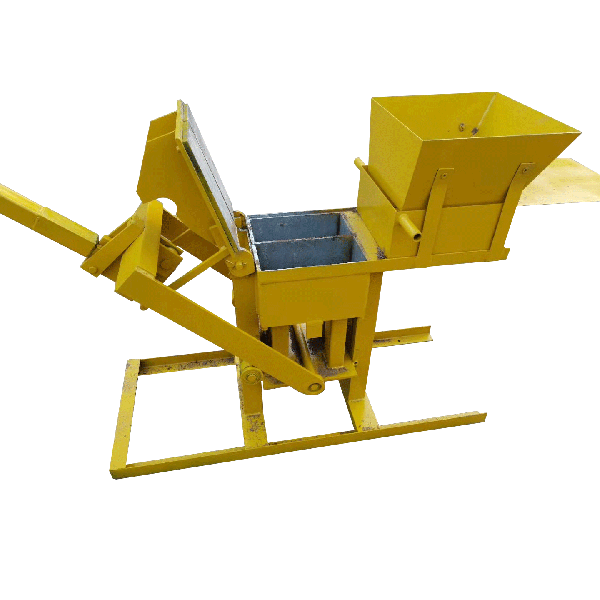

QTS2-40 Manual Clay Brick Making Machine

The QTS2-40 Manual Clay Brick Machine is an affordable, environmentally-friendly brick production solution that uses locally sourced soil, making it ideal for small-scale projects and home-based brick-making businesses.

Introduction Of QTS2-40 Manual Clay Brick Making Machine

The QTS2-40 Manual Clay Brick Machine is designed to produce high-quality clay bricks using locally sourced soil or mud as raw material, without the need for electricity or diesel fuel. Priced at an economical $1,000 per set (prices may vary), this brick-making machine is perfect for small-scale operations, especially in regions with limited power supply.

The QTS2-40 Manual Clay Brick Making Machine is capable of producing up to 1,920 pieces of 300x150x100mm bricks per day, with each brick moulding cycle taking only 30-40 seconds. The QTS2-40 can be used to make various types of bricks, including interlocking bricks, paver bricks,etc.Using customizable moulds. It is especially popular in African countries like South Africa, Tanzania, Mozambique, Botswana, and Zimbabwe, where it supports local construction and small building projects.

The machine’s simplicity, portability, and cost-effectiveness make it an ideal choice for both personal and small business use.

Advantages of the QTS2-40 Manual Clay Brick Making Machine

1. Cost-effective: With a price of only $1,000 per set, the QTS2-40 is an ideal choice for small home projects, animal enclosures, and budget-conscious construction ventures, making it affordable for local entrepreneurs.

2. Ease of Use: The fully manual operation means no technical expertise is required, making the QTS2-40 accessible to people with minimal training, ideal for first-time users or remote areas.

3. Portable: Designed to be compact and lightweight, the QTS2-40 can be easily moved from one construction site to another, ensuring flexibility for various projects and convenience in remote locations.

4. Environmentally Friendly: This machine’s operation is simple and eco-conscious, as it does not require electricity or diesel, and it uses manual pressing to form the bricks, minimizing its carbon footprint and energy consumption.

Get Free Quote of QTS2-40 Manual Clay Brick Making Machine

QTS2-40 Manual Clay Brick Machine Overview

The QTS2-40 Manual Clay Brick Machine is an affordable option, priced at $1,000 per set (price may vary in special cases). This manual machine is ideal for home use and operates without electricity or diesel, using soil or soil with a small amount of cement as raw materials.Produces various brick types, including interlocking bricks, paver bricks, and Lego bricks, with customized molds available to add logos.

Production Capacity:

- Brick Size: 300 × 150 × 100 mm

- Daily Output: 1,920 pieces (brick molding time: 30–40 seconds per cycle)

- Price Range: $1,000 USD, depending on mold specifications.

1. Manual Operation: The QTS2-40 is a fully manual brick-making machine, meaning it requires no external power source such as electricity or diesel, making it perfect for off-grid locations.

2. High Capacity: Capable of producing up to 1,920 bricks per day, the QTS2-40 is efficient and fast, with each brick moulding cycle taking just 30-40 seconds, boosting productivity.

3. Customizable Moulds: The machine can be used to create various types of bricks, including interlocking, paver,etc, with the option to customize moulds to suit different designs and sizes.

4. Durable and Portable: Built with high-quality materials, the QTS2-40 is designed for long-lasting durability, while its compact size allows for easy transport, making it suitable for both small and large-scale projects.

Paraments Of QTS2-40 Manual Clay Brick Making Machine

| Item | Paraments |

| Host brick machine | Dimension of host machine: 1600*700*1200mm

Shaping cycle: 40 seconds Pressure: 1000kgs Total weight: 260kgs Packing size: 1.4 CBM Packing method: Wooden case Power: No need power |

QTS2-40 Manual Clay Brick Making Machine Daily Production Capacity

| Size (mm) | Photo | Pieces/Mould | Pieces/Hour | Piece/day |

| 250x125x75mm |  |

2 | 240 | 1920 |

| 300x150x100mm |  |

2 | 240 | 1920 |

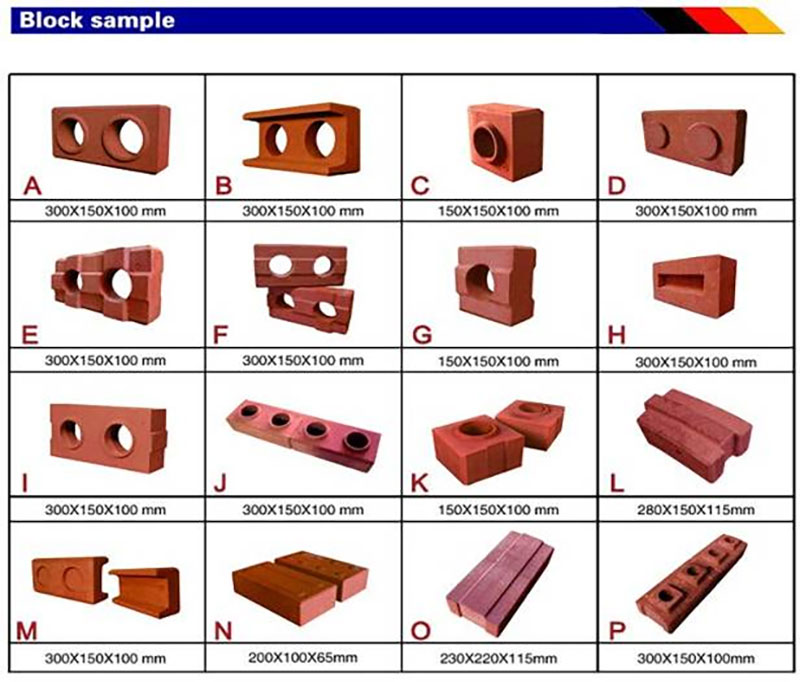

QTS2-40 Manual Clay Brick Making Machine- Sample Brick Showcase

Clients can review the clay brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

1. What raw materials are used for this clay brick machine?

The QTS2-40 clay brick machine uses local soil, clay, or mud as raw materials. In areas where the soil is pure mud, no cement is needed. However, if the soil contains sand, 5% to 10% cement is recommended to improve brick strength. The typical raw material composition is:

- Clay: 90%

- Cement: 6%–8%

- Water: 3%

2. What is the working process for the QTS2-40 Manual Clay Brick Machine?

The process is simple and involves the following steps:

- Load the mixed raw materials into the top hopper.

- Open the pressing head.

- Feed the raw materials into the mould box.

- Cover and lock the pressing head.

- Pull the pressing head handle to apply pressure.

- Open the press head to release the moulded brick.

- Push out the formed bricks from the mould.

- Move the bricks to the curing area for drying.

Working Videos

1. What raw materials are used for this clay brick machine?

The QTS2-40 clay brick machine uses local soil, clay, or mud as raw materials. In areas where the soil is pure mud, no cement is needed. However, if the soil contains sand, 5% to 10% cement is recommended to improve brick strength. The typical raw material composition is:

- Clay: 90%

- Cement: 6%–8%

- Water: 3%

2. What is the working process for the QTS2-40 Manual Clay Brick Machine?

The process is simple and involves the following steps:

- Load the mixed raw materials into the top hopper.

- Open the pressing head.

- Feed the raw materials into the mould box.

- Cover and lock the pressing head.

- Pull the pressing head handle to apply pressure.

- Open the press head to release the moulded brick.

- Push out the formed bricks from the mould.

- Move the bricks to the curing area for drying.

Related Products

Related News

The QTS2-40 manual clay brick making machine is a versatile and cost-effective solution for various construction and development projects. Its best […]

The QTS2-40 manual clay brick making machine is indeed an environmentally friendly solution for brick production. This innovative device operates without […]

The QTS2-40 manual clay brick making machine is a versatile and eco-friendly solution for producing high-quality bricks. This innovative manual clay […]

The QTS2-40 manual clay brick making machine is a cost-effective and eco-friendly solution for small-scale brick production. This versatile machine operates […]

The QTS2-40 manual clay brick making machine is highly portable and easy to move. Weighing less than many traditional block-making machines, […]

The QTS2-40 manual clay brick making machine demonstrates remarkable efficiency in brick production, offering a cost-effective and eco-friendly solution for small-scale […]

Yes, you can absolutely customize brick molds with the QTS2-40 manual clay brick making machine. This versatile and economical brick-making […]

In 2018, a valued client from Cameroon purchased two units of the QT40-2 manual block machine from Raytone Company, each […]