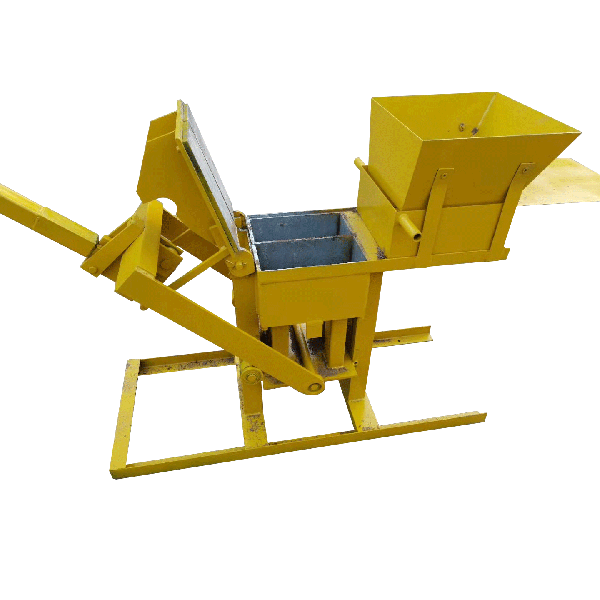

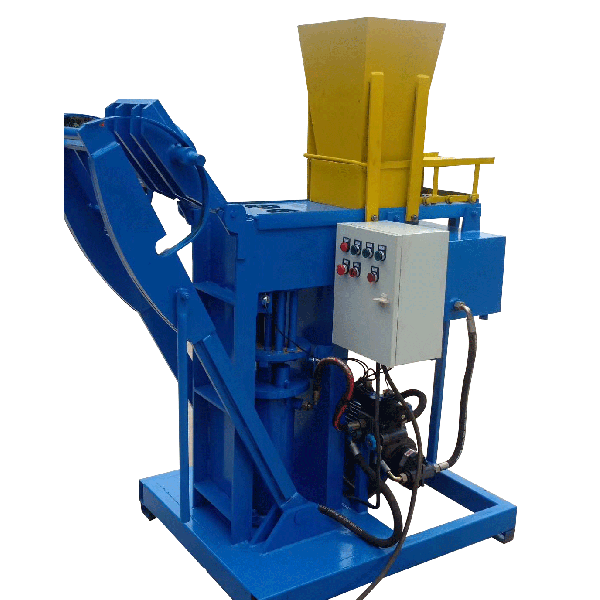

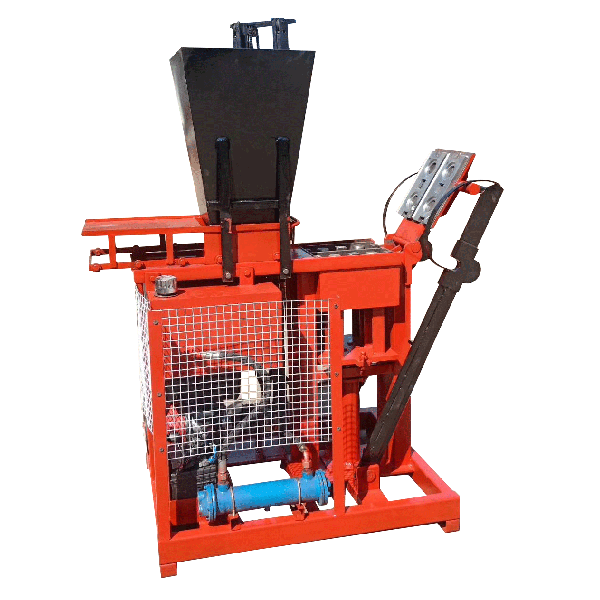

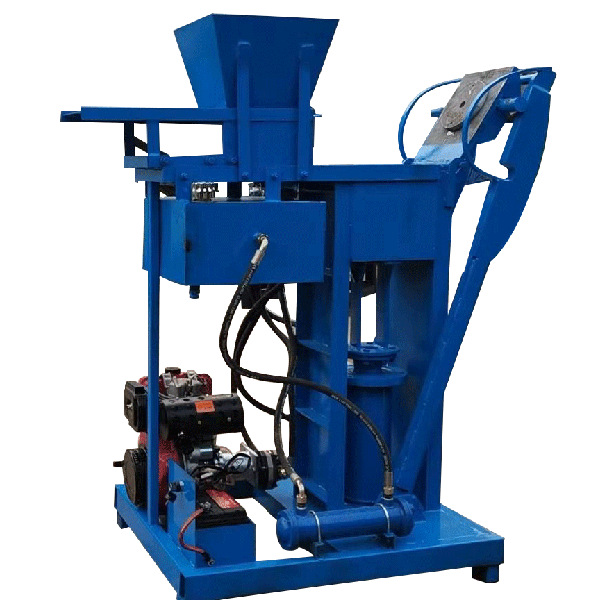

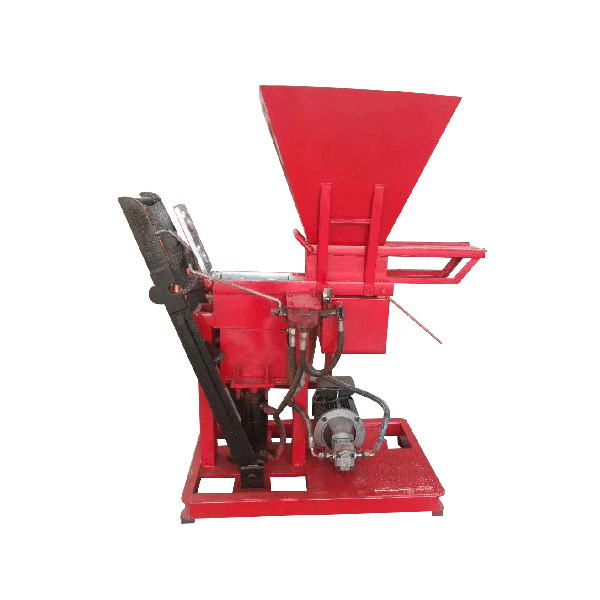

QTS2-25 Clay Brick Making Machine

The QTS2-25 Diesel Clay Brick Making Machine uses hydraulic pressing technology to produce various types of bricks such as clay bricks, interlocking bricks, or a clay-cement mix.

Introduction Of QTS2-25 Clay Brick Making Machine

The QTS2-25 Diesel Clay Brick Making Machine is an efficient and eco-friendly brick production machine designed for making soil, clay, or clay-cement mixture bricks. Featuring a hydraulic press system, this machine ensures high-density and high-quality brick production. It is capable of producing two bricks per mold with a cycle time of 25 seconds, offering a theoretical daily output of up to 2,304 pieces.

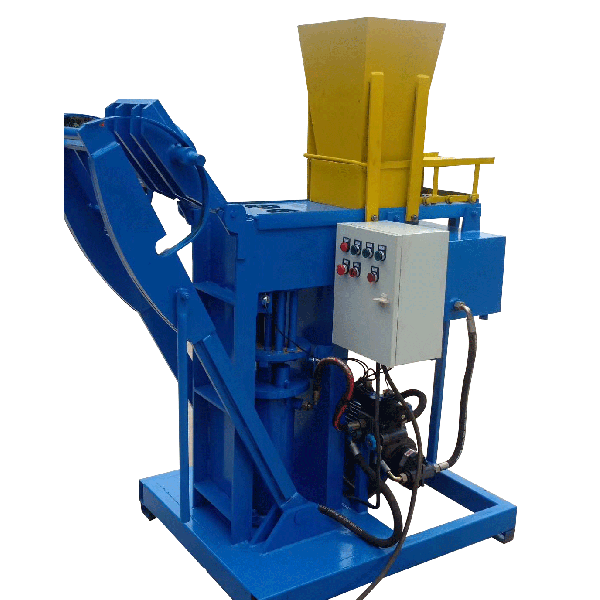

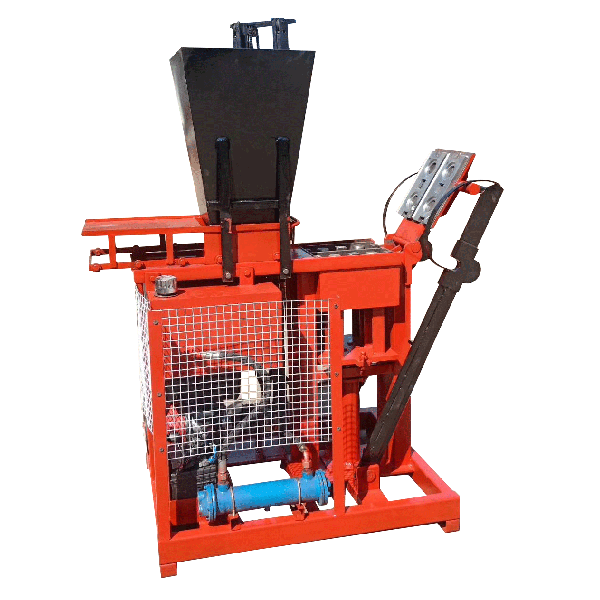

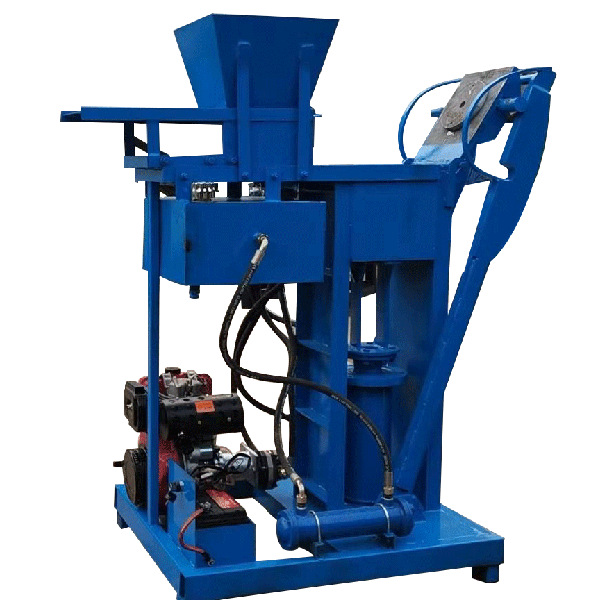

Available in both diesel engine and electric models, the QTS2-25 Clay Brick Making Machine is flexible to meet different working environments, especially suitable for areas without access to electricity with the diesel engine model. Additionally, the QTS2-25 Clay Brick Making Machine can be combined with other equipment, such as a soil crusher, soil screening machine, conveyor belt, and concrete mixer, to form a semi-automatic brick production line.

The QTS2-25 Clay Brick Making Machine is environmentally friendly, using only natural raw materials like soil and earth, and the production process requires no chemical additives.

The QTS2-25 is a great choice for both small-scale investments and commercial use, offering cost savings and ease of operation.

Advantages of the QTS2-25 Clay Brick Making Machine

1. Affordable Price, Suitable for Small Investment

The QTS2-25 Diesel Clay Brick Making Machine is priced competitively, making it a cost-effective solution for both small businesses and individual entrepreneurs. Its affordable cost of purchase, low maintenance expenses, and the ability to produce high-quality bricks with minimal investment make it ideal for those starting a brick-making business or for those who want to diversify their existing operations.

2. No Need for Brick Pallets, Saving on Costs

Unlike many concrete block machines that require the use of brick pallets, the QTS2-25 eliminates this additional cost. The machine can directly form bricks without needing a separate pallet, which not only reduces the operational costs but also lowers the storage space needed for pallets. This makes it a more economical choice for those with limited resources.

3. Easy to Operate, User-Friendly for Beginners

The QTS2-25 is designed to be intuitive and simple to operate. It doesn’t require specialized skills or extensive training, making it an excellent choice for small businesses and first-time operators. The machine’s user-friendly controls allow for efficient and straightforward operation, reducing the learning curve and minimizing errors during production.

4. Diesel Engine Model for Flexibility in Off-Grid Locations

The QTS2-25 is available in both electric and diesel engine models. The diesel-powered version provides unparalleled flexibility, allowing the machine to be used in remote areas or construction sites where access to electricity is unavailable. This mobility makes it an attractive choice for construction projects in off-grid locations, offering a reliable solution without the need for an external power supply.

Get Free Quote of QTS2-25 Clay Brick Making Machine

QTS2-25 Clay Brick Making Machine Overview

The QTS2-25 Clay Brick Making Machine offers advanced functionality with options for diesel or electric power. It produces high-quality bricks using soil, clay, or a mix of clay and cement through hydraulic pressing.

Supports the production of clay bricks, interlocking bricks, and Eco Brava bricks.

Production Capacity:

- Brick Size: Varies by mold

- Daily Output: 2,304 pieces (two bricks per mold, 25 seconds per cycle)

1. Dual Mold Production for Efficiency: The QTS2-25 Clay Brick Making Machine is designed to produce two bricks per mold, doubling the efficiency compared to single-mold machines. With a cycle time of just 25 seconds, this feature allows for faster production, increasing output and reducing the time required to meet production targets. This is especially beneficial for large-scale production and commercial businesses that need to meet higher demand.

2. Customizable Production Line: In addition to its primary brick-making function, the QTS2-25 Clay Brick Making Machine can be integrated with additional equipment, such as a soil crusher, soil screening machine, conveyor belt, and concrete mixer, forming a semi-automatic brick production line. This flexibility allows businesses to expand their operations, streamline the production process, and improve overall efficiency, reducing manual labor and increasing automation in the production process.

3. Adjustable Hydraulic Pressure: The hydraulic pressure of the QTS2-25 Clay Brick Making Machine can be adjusted between 16-25 MPA, allowing users to customize the density of the bricks being produced. This feature provides great flexibility in producing bricks of varying strength and quality. By adjusting the pressure, the machine can produce bricks suitable for different construction needs, whether for lighter applications or more demanding structural uses.

4. Eco-Friendly Materials: The QTS2-25 Clay Brick Making Machine uses natural raw materials like soil and earth to produce bricks, with no chemical additives required. This eco-friendly production method ensures that the brick-making process is sustainable and environmentally responsible. The bricks produced by this machine are free from harmful chemicals, making them safe for use in construction and contributing to sustainable building practices.

Detailed Introduction of QTS2-25 Clay Brick Making Machine

| Number | Item | Function |

| 1 | Diesel engine | Supply big power for brick machine press |

| 2 | Key Start | Start diesel engine with key ( electric start) |

| 3 | Hydraulic Cylinder | Produce bricks with high strength |

| 4 | Brick Machine Mold | Changing molds for different sizes of bricks |

| 5 | Hydraulic Oil Tank | Storage of hydraulic oil |

| 6 | Water cooling system | Make hydraulic oil cool when oil is hot |

Paraments Of QTS2-25 Clay Brick Making Machine Host Machine

| Item | Paraments |

| Host brick machine | Dimension of host machine: 1600*820*1700mm

Moulding period:20-25s Host machine power:7.5kw Weight:400kg Daily productivity:2304 pieces Diesel engine:12 HP |

QTS2-25 Clay Brick Making Machine Daily Production Capacity

| Size (mm) | Photo | Pieces/Mould | Pieces/Hour | Piece/day | Pcs/month |

| 300*150*100 |  |

2 | 300 | 2400 | 72000 |

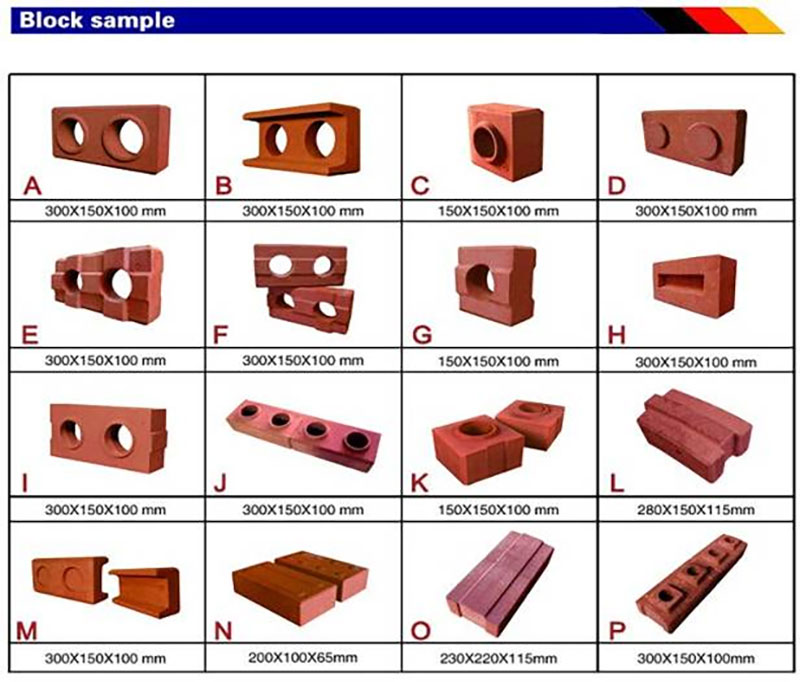

QTS2-25 Clay Brick Making Machine - Sample Brick Showcase

Clients can review the clay brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

1. How do you operate the QTS2-25 Clay Brick Making Machine?

Operating the QTS2-25 Clay Brick Making Machine is simple:

- First, load the raw materials into the block mould.

- Next, cover the pressing head and pull the hydraulic tank lever to apply the required pressure.

- Afterward, open the pressing head, pull the hydraulic lever again to eject the formed bricks.

- Finally, move the bricks to the curing area.

2. How many workers are required to operate the QTS2-25 Clay Brick Making Machine?

The QTS2-25 Clay Brick Making Machine can be operated by three workers:

- One worker manages the concrete mixer, feeding raw materials into the mixer and discharging the well-mixed materials onto the belt conveyor.

- A second worker operates the main soil brick machine.

- The third worker transports the formed bricks to the curing area.

Working Videos

1. How do you operate the QTS2-25 Clay Brick Making Machine?

Operating the QTS2-25 Clay Brick Making Machine is simple:

- First, load the raw materials into the block mould.

- Next, cover the pressing head and pull the hydraulic tank lever to apply the required pressure.

- Afterward, open the pressing head, pull the hydraulic lever again to eject the formed bricks.

- Finally, move the bricks to the curing area.

2. How many workers are required to operate the QTS2-25 Clay Brick Making Machine?

The QTS2-25 Clay Brick Making Machine can be operated by three workers:

- One worker manages the concrete mixer, feeding raw materials into the mixer and discharging the well-mixed materials onto the belt conveyor.

- A second worker operates the main soil brick machine.

- The third worker transports the formed bricks to the curing area.

Related Products

Related News

The QTS2-40 manual clay brick making machine is a versatile and cost-effective solution for various construction and development projects. Its best […]

The QTS2-40 manual clay brick making machine is a versatile and eco-friendly solution for producing high-quality bricks. This innovative manual clay […]

The QTS2-40 manual clay brick making machine is a cost-effective and eco-friendly solution for small-scale brick production. This versatile machine operates […]

The QTS2-40 manual clay brick making machine is highly portable and easy to move. Weighing less than many traditional block-making machines, […]

The QTS2-40 manual clay brick making machine demonstrates remarkable efficiency in brick production, offering a cost-effective and eco-friendly solution for small-scale […]

The QMY4-45 diesel movable block making machine stands out for its user-friendly design, making it exceptionally easy to operate even for […]

The QT4-10 automatic clay brick making machine primarily utilizes soil and a small amount of cement as its main raw materials. […]

Proper maintenance of a QT4-10 automatic clay brick making machine is crucial for ensuring its longevity, efficiency, and consistent production of […]