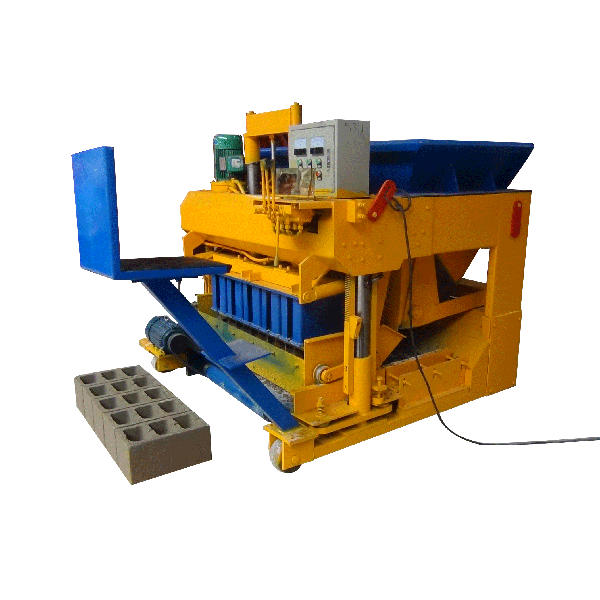

QTM6-25 Automatic Mobile Block Machine

The QTM6-25 Mobile Concrete Block Machine is a versatile, high-productivity machine that produces various types of blocks, including hollow, solid, and paver bricks, without the need for pallets.

Introduction Of QTM6-25 Automatic Mobile Block Machine

he QTM6-25 Mobile Concrete Block Machine is designed for high-efficiency block production without requiring pallets, offering significant cost savings in the block-making process. This machine operates on concrete ground, making it mobile and flexible but requiring a larger space for movement. It features a two-times vibration system, enhancing the block density and speeding up the shaping process.

With a production capacity of 6800-8800 pieces of 8-inch hollow blocks per day, the QTM6-25 can meet the demands of small to medium-scale construction projects. The machine is powered by 3-5 workers and requires 1000-1500 square meters of land area.

Recent technological improvements enable the QTM6-25 to produce a range of block types, including hollow blocks, solid blocks, and paver bricks, offering versatility for various construction needs.

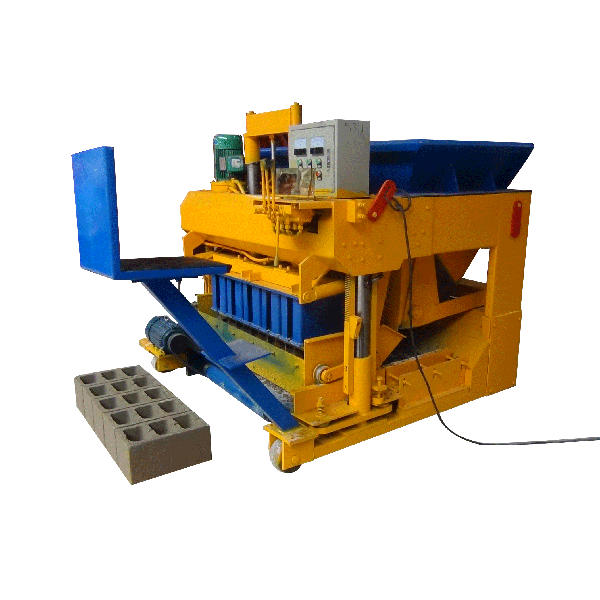

Advantages of the QTM6-25 Automatic Mobile Block Machine

1. Mobile and Flexible: Operates without the need for pallets, saving costs and increasing mobility.

2. High Productivity: Capable of producing 6800-8800 pieces of 8-inch hollow blocks per day, making it ideal for medium-scale projects.

3. Cost-Effective: No pallet requirement reduces costs and prevents secondary block damage.

4. Improved Technology: Can now produce a variety of block types, including hollow blocks, solid bricks, and paver bricks.

Get Free Quote of QTM6-25 Automatic Mobile Block Machine

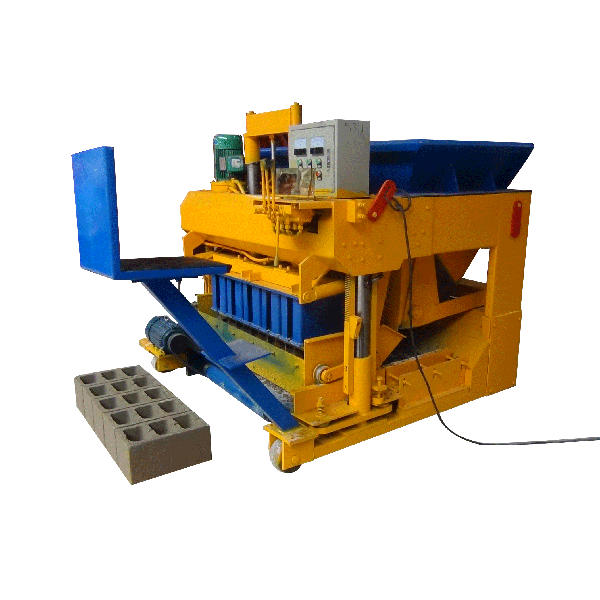

QTM6-25 Mobile Concrete Block Machine Overview

The QTM6-25 Mobile Concrete Block Machine operates directly on concrete ground without the need for brick pallets, significantly reducing costs. This machine features two-times vibration, resulting in higher block density and faster shaping speed.

Production Capacity:

- 8-inch Hollow Blocks: 6,800–8,800 pieces per day

- Price Range: About $9,500 USD, with the final price varying based on specific configuration and mold requirements.

1. Mobile Design: Easily movable on concrete surfaces without the need for pallets.

2. Two-Times Vibration: Ensures higher block density and faster shaping speed.

3. Large Land Requirement: Requires 1000-1500 square meters for efficient operation.

4. Multiple Block Types: Capable of producing hollow blocks, solid bricks, and paver bricks for versatile use.

Detailed Introduction of QTM6-25 Automatic Mobile Block Machine Making Line

| Number | Item | Function |

| 1 | Batching machine | Ensure precise material proportioning for consistent block quality. |

| 2 | JS500 Concrete Mixer | Mix raw material and water. |

| 3 | Hopper truck | Transport bulk materials efficiently. |

| 4 | Host Brick Machine | Produce different sizes of bricks. |

QTM6-25 Automatic Mobile Block Machine Daily Production Capacity

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 6800-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 8000-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 9600-11200 |

Paraments Of QTM6-25 Automatic Mobile Block Machine Host Machine

| Item | Paraments |

| Host brick machine | Mould cycle: 25S

Hydraulic pressure: 6-8Mpa Capacity: 8000-10000 pcs Total power: 12kw Voltage: 415v; 50HZ Diemension: 2250*2200*1750mm Weight: 2600kg |

QTM6-25 Automatic Mobile Block Machine Daily Production Capacity

| Size (mm) | Qty/mould | mould cycle (s) | capacity per hour | daily capacity |

| hollow 400*200*200 | 6 | 20-25 s | 850-1100 | 6800-8800 |

| hollow 400*150*200 | 7 | 20-25 s | 1000-1300 | 8000-10400 |

| hollow 400*100*200 | 18 | 20-25 s | 1200-1400 | 9600-11200 |

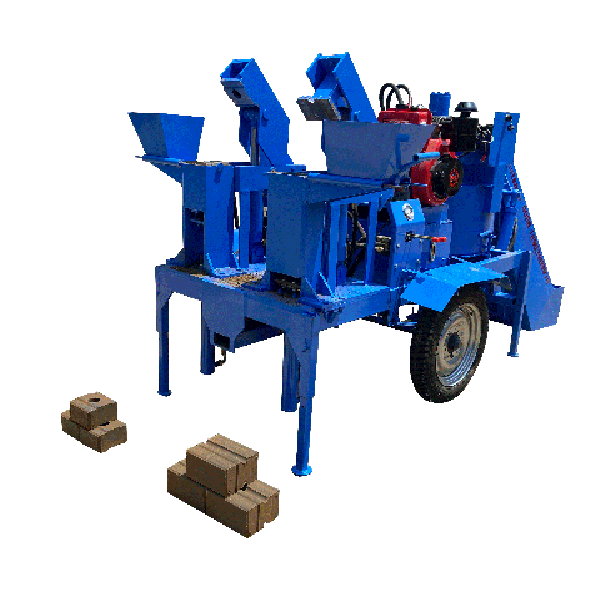

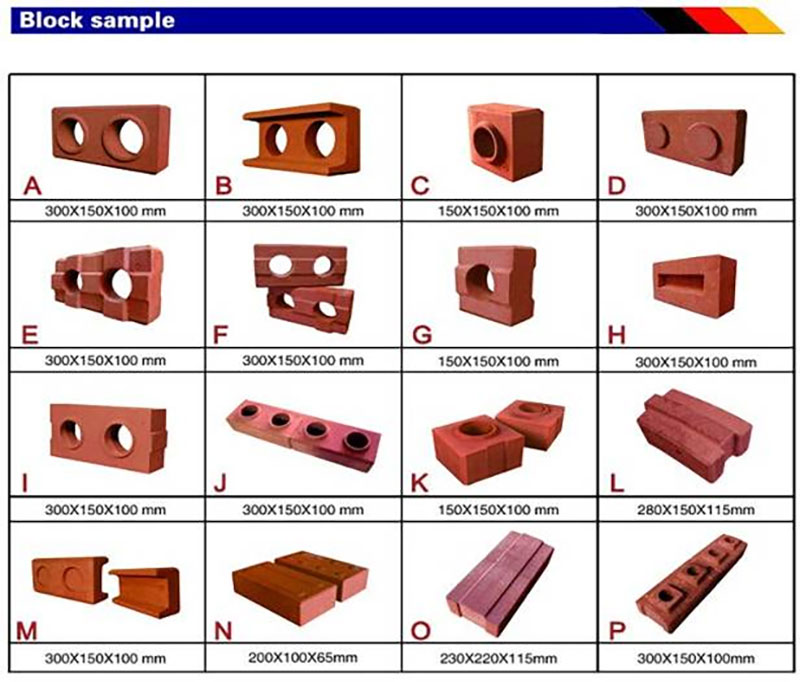

QTM6-25 Automatic Mobile Block Machine - Sample Brick Showcase

Clients can review the clay brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Related Products

Related News

The QTS2-40 manual clay brick making machine is a versatile and cost-effective solution for various construction and development projects. Its best […]

The QTM4-45 mobile block machine is revolutionizing small-scale block production. This compact and versatile equipment offers numerous benefits for construction projects […]

Yes, the M7MI TWIN diesel hydraform soil brick machine is a versatile piece of equipment capable of producing various types of […]

The M7MI TWIN diesel hydraform soil brick machine offers numerous advantages for construction projects, particularly in remote or off-grid locations. This […]

Yes, the M7MI TWIN diesel hydraform soil brick machine is indeed mobile. This innovative block-making machinery is designed with portability in […]

The M7MI TWIN diesel hydraform soil brick machine is powered by a robust diesel engine, providing an independent and versatile power […]

The QMY4-45 diesel movable block making machine stands out as a versatile powerhouse in the construction industry. This portable block production […]

The QMY4-45 diesel movable block making machine stands out for its user-friendly design, making it exceptionally easy to operate even for […]