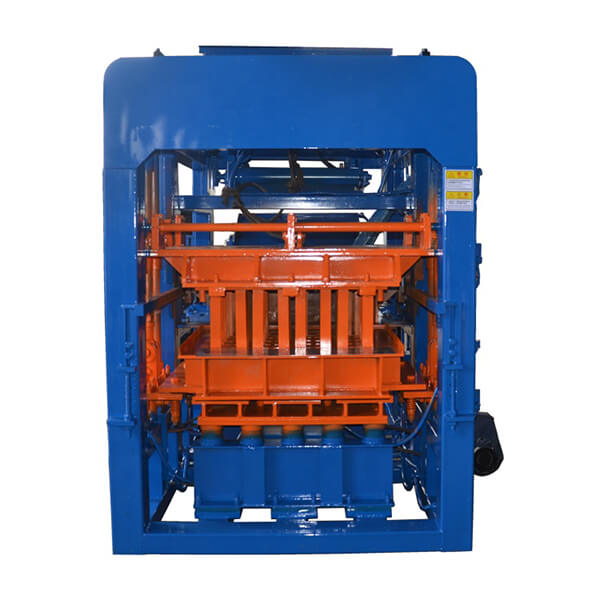

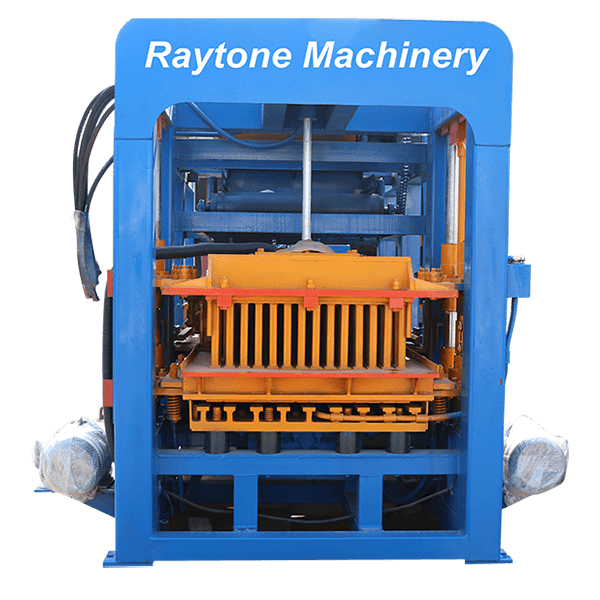

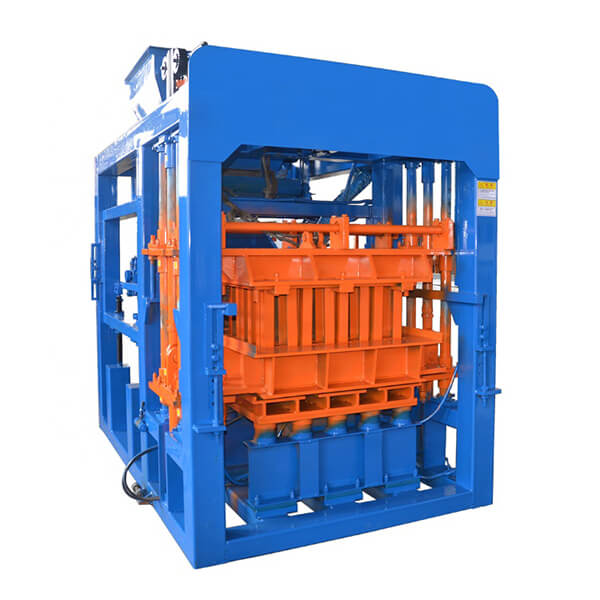

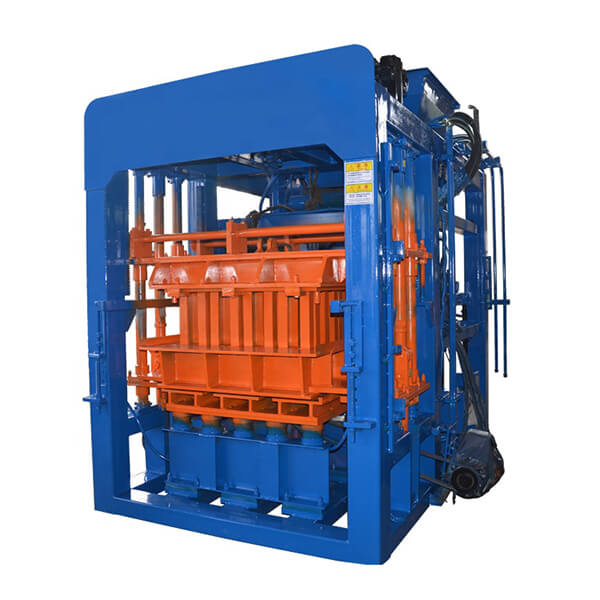

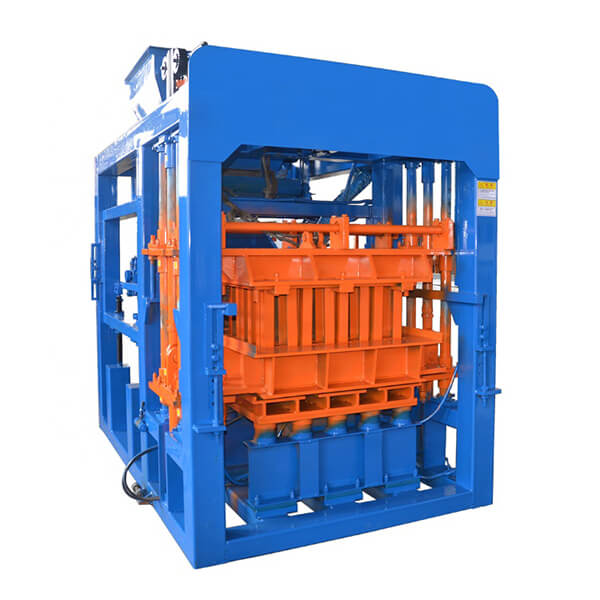

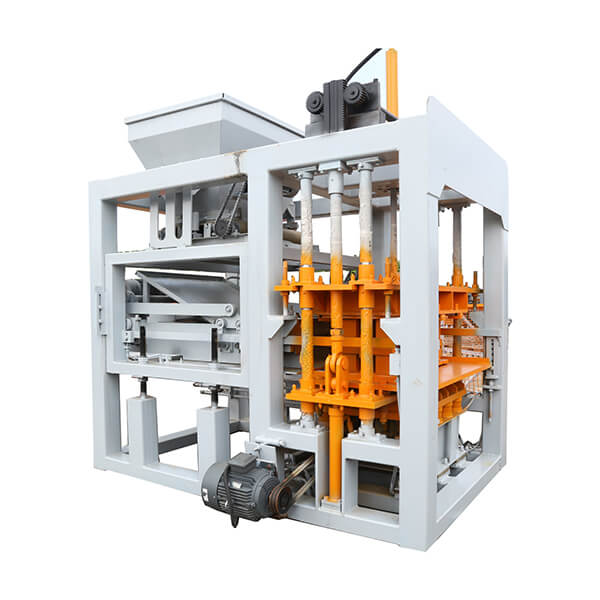

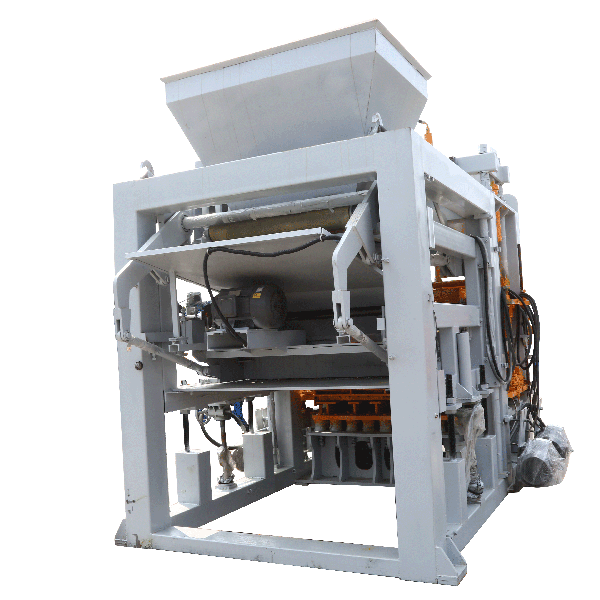

QT6-15 Full-automatic Block Making Machine

The QT6-15 is a highly efficient, fully automated medium-scale concrete block machine suitable for producing various types of blocks such as standard bricks, hollow bricks, and colored pavers.

Introduction Of QT6-15 Full-automatic block making machine

The QT6-15 Full-automatic block making machine is a medium-sized, fully automated concrete block machine designed for high-efficiency production of a variety of block types, including standard blocks, hollow blocks, colored pavers, and curbstones.

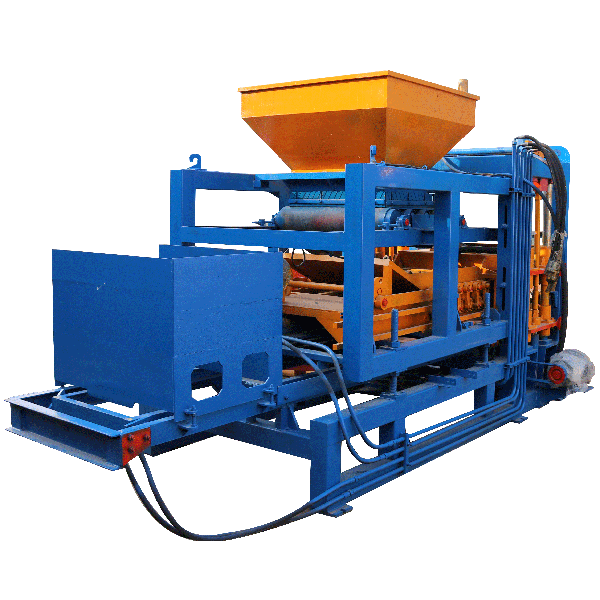

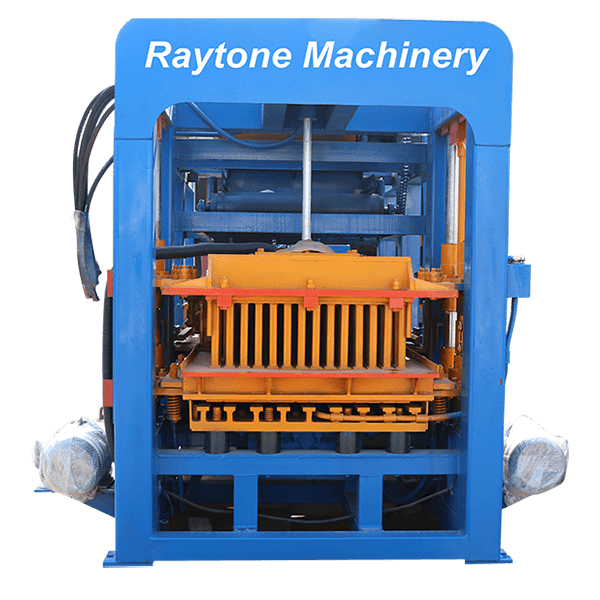

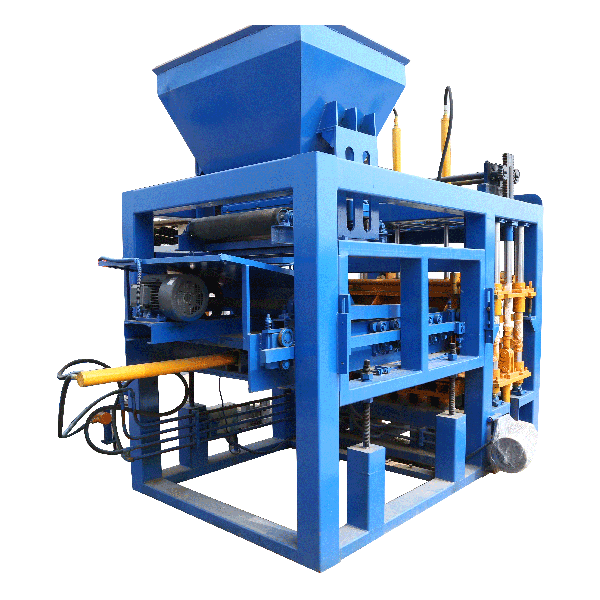

The QT6-15 Full-automatic block making machine is equipped with a 2- or 3-bin batching machine, a 500-liter twin-shaft concrete mixer, and an automatic wet block stacking system. The machine is controlled via a user-friendly PLC touch screen, which facilitates straightforward and intuitive operation.

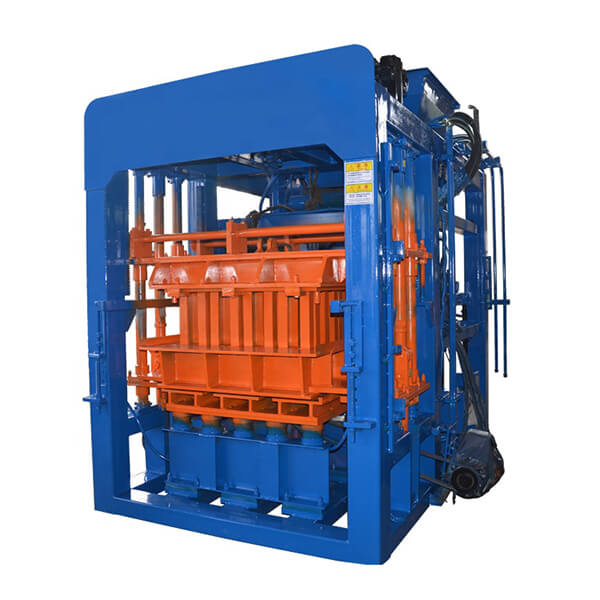

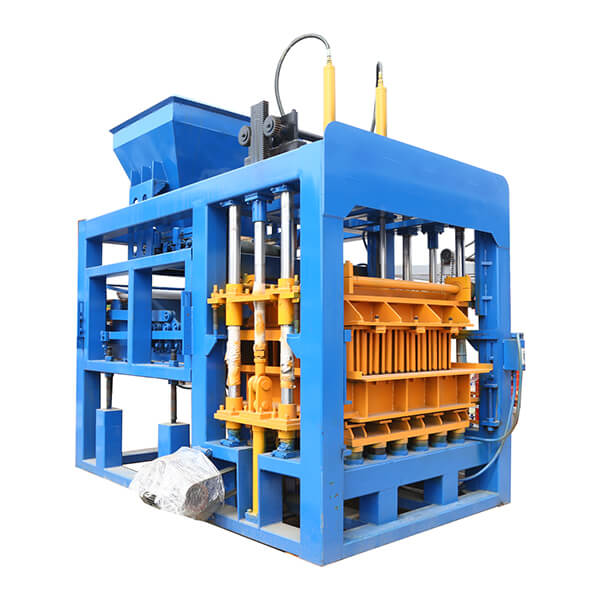

The mold is interchangeable, allowing for the production of a wide range of block types. It features a stable vibration system that ensures high-density, high-strength bricks. The QT6-15’s advanced vibration technology employs low-frequency feeding and high-frequency vibration to fully liquefy and de-air the concrete within 2-3 seconds, ensuring the production of durable, high-strength blocks that can be stacked immediately after formation.

The machine’s automation reduces the need for skilled labor, making it a cost-effective solution for businesses of various sizes.

Advantages of the QT6-15 Full-automatic block making machine

1. High Efficiency:

The QT6-15 Full-automatic block making machine utilizes advanced vibration technology to optimize concrete compaction in just 2-3 seconds, reducing energy consumption while increasing production output. This efficient system ensures high-density, high-strength blocks with minimal energy use, improving overall operational efficiency.

2. Versatile Production:

With interchangeable molds, the QT6-15 Full-automatic block making machine can produce a variety of blocks, including standard, hollow, multihole, and colored pavers. This flexibility allows manufacturers to cater to different market demands, providing a wide range of products without additional investment in separate machines.

3. High Automation:

The machine’s fully automated systems—batching, mixing, and stacking—reduce labor requirements and improve consistency. The user-friendly PLC control system ensures easy operation and minimal downtime, boosting production efficiency and reducing human error in the manufacturing process.

4. Energy and Resource Efficient:

The QT6-15’s rapid liquefaction technology ensures optimal concrete compaction, reducing material waste and lowering production costs. Its energy-efficient hydraulic and electrical systems minimize power consumption, helping to lower operational expenses while maintaining high-quality brick production.

Get Free Quote of QT6-15 Full-automatic Block Making Machine

QT6-15 Automatic Hydraulic Brick Making Machine Overview

The QT6-15 Automatic Hydraulic Brick Making Machine combines hydraulic press and big vibration to produce high-strength blocks. It is multi-functional, capable of producing hollow blocks, solid bricks, interlocking pavers, and hourdis by changing molds.

- Production Capacity: 8-inch Hollow Blocks: Up to 11,520 pieces per day.

- Price Range: $28,800 to $39,850 USD, depending on the production line configuration.

1. User-Friendly Control:

The QT6-15 is equipped with a PLC touch screen, making it easy to operate and monitor. The intuitive interface allows operators to quickly adjust settings without extensive technical training. This simplifies machine operation, reduces the need for skilled labor, and ensures efficient management of the production process.

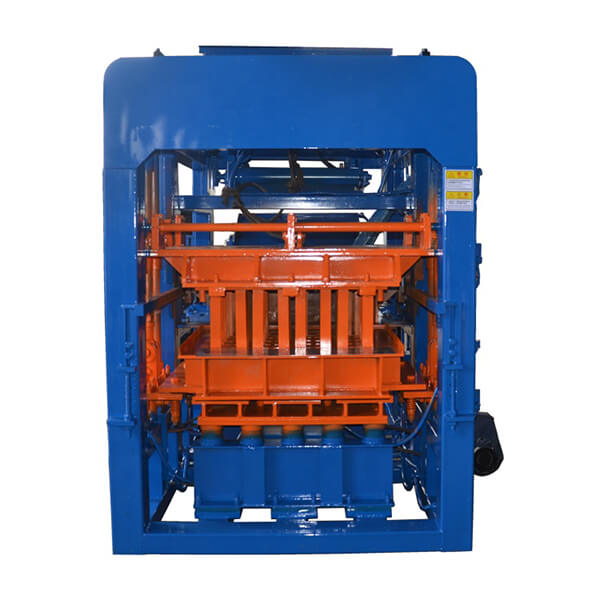

2. Advanced Vibration System:

The machine’s dual-frequency vibration system (low-frequency feeding, high-frequency vibration) ensures optimal compaction of concrete. This system efficiently de-airs and liquefies the mixture in just 2-3 seconds, producing high-strength blocks with minimal air pockets, which is essential for durable, high-quality brick production.

3. Reliable Hydraulic and Electrical Systems:

The QT6-15 uses imported hydraulic and electrical components, ensuring reliable and stable performance. These high-quality systems are less prone to failure, reducing maintenance costs and downtime. This ensures consistent operation, higher productivity, and longer machine life with minimal disruptions.

4. High Production Capacity:

With the ability to produce up to 11,520 8-inch blocks or 63,360 solid bricks per 8-hour shift, the QT6-15 is highly productive. This capacity allows manufacturers to meet high-volume demands efficiently, ensuring quick turnaround times and enabling them to scale production as needed.

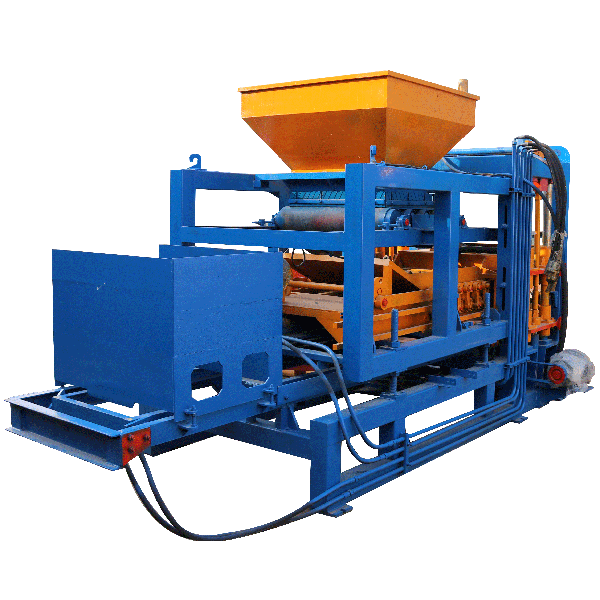

Detailed Introduction of QT6-15 Full-automatic block making machine

| Number | Item | Function |

| 1 | Batching Machine | Batch raw material automatically |

| 2 | JS500 Pan Mixer | Mix raw material including cement, sand, stone |

| 3 | 8m Belt Conveyor | Carry Mixed material from mixer to Block machine |

| 4 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 5 | Hydraulic Station | Supply Hydraulic Press |

| 6 | Automatic PLC | Automatic PLC Control for block machine |

| 7 | Automatic Stacker | Stack the finished hollow blocks to several layers |

Paraments Of QT6-15 Full-automatic block making machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area:200 square meters

Factory area:1200 square meters Labor quantity:4 Moulding area: 861x880mm Vibration Frequency: 4600 times/M Machine power:33.7kw Vibration force:70-90 KN Moulding Period:12-20 S Diesel Generator Capacity: 100KVA Machine size: 4350*1560*2400mm Machine weight: 8000kg |

QT6-15 Full-automatic block making machine Daily Production Capacity

| QT6-15 Full-automatic block making machine | ||||||

| Size(LxWxH) (mm) | Forming Period (S) | Photo | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 | 15 |  |

4 | 960 | 7680 |

| (2) | hollow block 400*200*200 | 15 |  |

6 | 1440 | 11520 |

| (3) | hollow block 400*150*200 | 15 |  |

8 | 1920 | 15360 |

| (4) | hollow block 400*100*200 | 15 |  |

12 | 2880 | 23040 |

| (5) | Solid Brick 240*50*115 | 15 |  |

33 | 7920 | 63360 |

| (6) | Porous Brick 240*115*90 | 15 |  |

15 | 3600 | 28800 |

| (7) | Hourdis Block 500*150*200mm | 15 |  |

5 | 1200 | 9600 |

| (8) | Curbstone 500*200*300 | 15 |  |

2 | 480 | 3840 |

| (9) | “I” shape paver brick without color 200*163*60 | 15 |  |

15 | 3600 | 28800 |

| (10) | “S” Shape Paver Brick without color 225*112.5*60 | 15 |  |

15 | 3600 | 28800 |

| (11) | Holland Brick without color 200*100*60 | 15 |  |

24 | 5760 | 46080 |

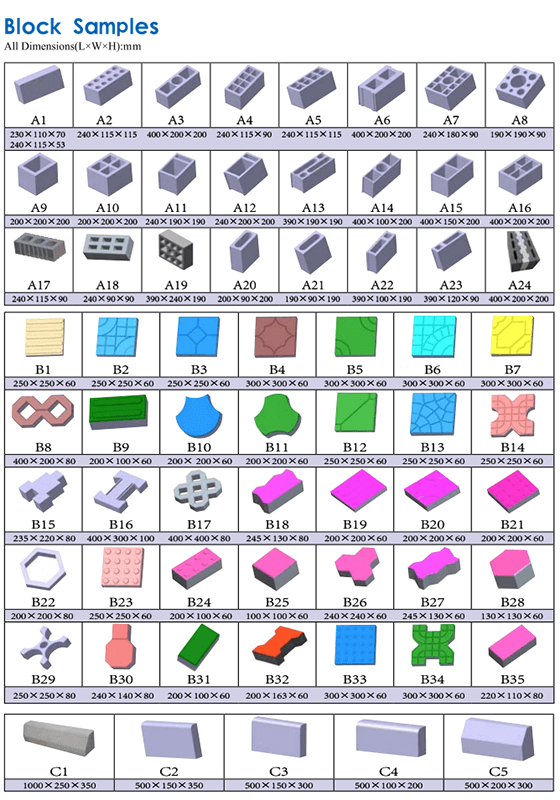

QT6-15 Full-automatic block making machine - Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT6-15 Full-automatic block making machine Full Production Line

| 1 | PLD1200 concrete batching machine | 1 set |

| 2 | JS500 concrete mixer | 1 set |

| 3 | 8M Belt Conveyor | 1 set |

| 4 | QT6-15 Host Brick Machine | 1 set |

| 6 | PLC control Panel | 1 set |

| 7 | Hydraulic Station | 1 set |

| 8 | JQ350 Pigment Mixer | 1 set |

| 9 | Pigments feeding machine | 1 set |

| 10 | hollow blocks Stacking Machines | 1 set |

| 11 | Manual trolleys | 2 set |

| 12 | Brick Pallet Loading Machine | 1 set |

| 13 | GMT brick pallet | 1200 pieces |

| 14 | Spare parts | 1 set |

(1) What is the packing method?

The machine can be packed in different ways: nude packing, plastic wrapping, or in a plywood box, depending on customer requirements.

(2) Which motor and electrical brand do we use for the machine?

We use Siemens brand motors and electrical components, or alternatively, well-known Chinese brands for reliable performance.

(3) What type of steel is used for the machine and molds?

The machine is made of Q235B steel, and the molds are made from Mn steel, which is known for its durability and long-lasting performance.

(4) Will you send engineers to install the machine?

Yes, we have a dedicated technician service team. They will provide installation and commissioning services as per customer requirements.

(5) Are spare parts included with the machine?

Yes, we will provide spare parts along with the machine. These parts are designed to last for over two years, ensuring uninterrupted production.

(6) Do you offer free technical support during production?

Yes, we provide 24-hour online technical support to assist with any issues or questions during production.

(7) What is the warranty period for the machine?

The machine comes with a 1-year warranty, excluding wear-and-tear parts. If any quality issues arise within this period, we will cover the shipping costs for replacements.

Working Videos

(1) What is the packing method?

The machine can be packed in different ways: nude packing, plastic wrapping, or in a plywood box, depending on customer requirements.

(2) Which motor and electrical brand do we use for the machine?

We use Siemens brand motors and electrical components, or alternatively, well-known Chinese brands for reliable performance.

(3) What type of steel is used for the machine and molds?

The machine is made of Q235B steel, and the molds are made from Mn steel, which is known for its durability and long-lasting performance.

(4) Will you send engineers to install the machine?

Yes, we have a dedicated technician service team. They will provide installation and commissioning services as per customer requirements.

(5) Are spare parts included with the machine?

Yes, we will provide spare parts along with the machine. These parts are designed to last for over two years, ensuring uninterrupted production.

(6) Do you offer free technical support during production?

Yes, we provide 24-hour online technical support to assist with any issues or questions during production.

(7) What is the warranty period for the machine?

The machine comes with a 1-year warranty, excluding wear-and-tear parts. If any quality issues arise within this period, we will cover the shipping costs for replacements.

Related Products

Related News

In the block machine industry, the choice of pallets is a critical decision that directly impacts productivity, product quality, and […]

The QT6-15 automatic block making machine is a versatile and high-performance concrete block production solution capable of manufacturing a wide variety […]

The QT6-15 automatic block making machine comes with a comprehensive warranty and exceptional after-sales service. Raytone Machinery offers a 12-month warranty […]

The QT6-15 automatic block making machine revolutionizes concrete block production, offering a seamless process from raw materials to finished products. This […]

In today’s construction industry, energy efficiency and cost-saving measures are paramount. The QT6-15 automatic brick making machine stands out. This advanced […]

The QT6-15 automatic block making machine boasts an impressive production capacity, making it a powerhouse in the concrete block manufacturing industry. […]

In the ever-evolving world of construction, the ability to customize and adapt is paramount. The QT6-15 automatic brick making machine stands […]