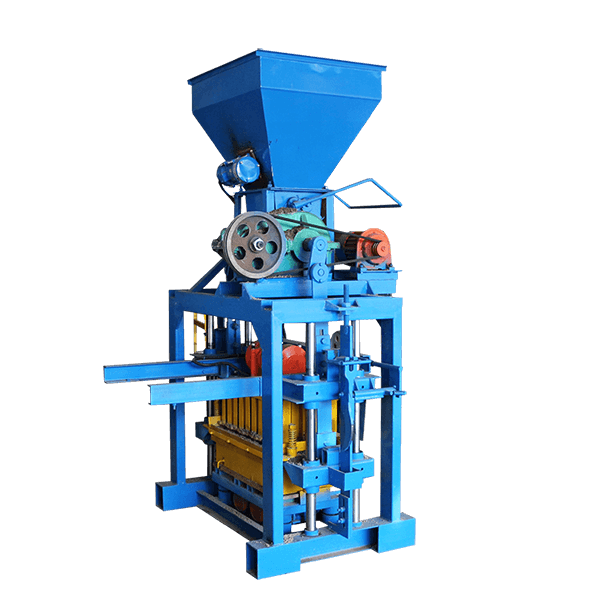

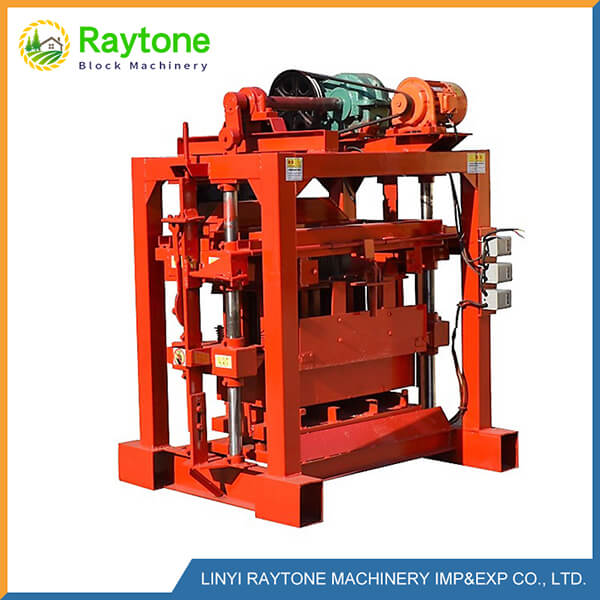

QT4-40 Manual Block Machine

The QT4-40 manual block machine is a cost-effective, easy-to-operate brick machine ideal for small-scale investors and beginners.

Introduction Of QT4-40 Manual Brick Making Machine

The QT4-40 manual block machine is designed for simplicity and ease of use, requiring minimal training for effective operation. This budget-friendly machine is suitable for small investment projects, producing up to 2,880 pieces of 8-inch hollow blocks daily. It is compact and portable, making it convenient to move and set up at different work sites as needed.

The QT4-40 Manual Brick Making Machine’s key components include the JQ350 concrete mixer, bottom and top vibrators, and molds made from durable #16 manganese steel. RAYTONE also provides high-quality GMT pallets and a manual trolley to support production.

With a required workspace of just 20 square meters and a team of only 4 workers, the QT4-40 Manual Brick Making Machine is ideal for small projects or home-based brick-making setups.

Advantages of the QT4-40 Manual Brick Making Machine

1. User-friendly operation: The QT4-40 manual block machine is designed with simplicity in mind, allowing users to easily operate the machine after a short period of training. This straightforward functionality reduces the need for highly skilled labor, making it accessible to small business owners and new entrants to the brick industry.

2. Portability and Flexibility: Due to its compact and lightweight design, the QT4-40 Manual Brick Making Machine is highly portable, making it easy to move to different locations as production needs change. This mobility provides flexibility for small businesses or home production, allowing users to quickly adapt to changing workspaces or customer demands.

3. Cost-effective investment: As an affordable machine option, the QT4-40 Manual Brick Making Machine is an ideal choice for those looking to make a small investment without compromising quality. It offers a high return on investment for small projects and home-based businesses thanks to its reliable output and low maintenance requirements.

4. Low maintenance requirements: The QT4-40 Manual Brick Making Machine is designed for low maintenance, requiring only basic upkeep to ensure smooth operation. Daily cleaning of the concrete mixer and block molds, along with occasional lubrication of moving parts, helps extend the life of the machine. This low-maintenance setup keeps operating costs down and downtime to a minimum, which is especially beneficial for new and small operators.

Get Free Quote of QT4-40 Manual Block Machine

QT4-40 Manual Block Machine Overview

The QT4-40 manual block machine is user-friendly and easy to operate, requiring minimal training for workers. Its affordable price makes it ideal for small-scale investors.

- Production Capacity: 8-inch Hollow Blocks: 2,880 pieces per 8-hour shift.

- Price Range: $3,700 to $10,000 USD, depending on the number of molds.

1. High production capacity for its size: Despite its small size, the QT4-40 block machine can produce up to 2,880 8-inch hollow blocks per day. This production capacity is impressive for a manual machine and allows users to meet moderate production needs and efficiently fill small to medium sized orders.

2.Durable and Long-Lasting Materials: The components of the QT4-40 block machine are made of high-quality materials to ensure longevity. Its block molds are made of #16 manganese steel, which is highly resistant to wear and tear, ensuring a long service life. This durability minimizes the frequency of mold replacement, reducing long-term operating costs.

3. Space-efficient design: The QT4-40 is compact and requires only a 20-square-foot work area to set up. This small footprint is ideal for confined spaces, whether on a construction site, in a small workshop or even in a home production area, making it versatile for businesses with limited space.

QT4-40 Manual Brick Making Machine Basic Requirements for Production Start

| Land area | 200 Square Meters | Water Consumption | 1.6 T/day |

| Workshop area | 20 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 4workers | Power Consumption | 17.9KW*8 Hours=143.2 KWH; |

| Cement Consumption | 4.7 Tons per day | Sand consumption | 19 tons per day |

| Crushed stones consumption | 23.7 tons per day |

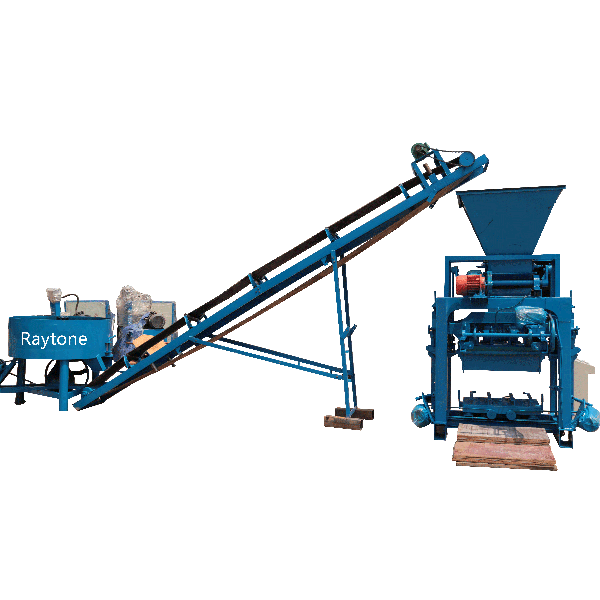

Detailed Introduction of QT4-40 Manual Brick Making Machine Line

| Number | Item | Function |

| 1 | JQ350 Concrete mixer | Mix raw material including cement, sand, stone |

| 2 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 3 | Manual Trolley | Transport the produced blocks to curing area |

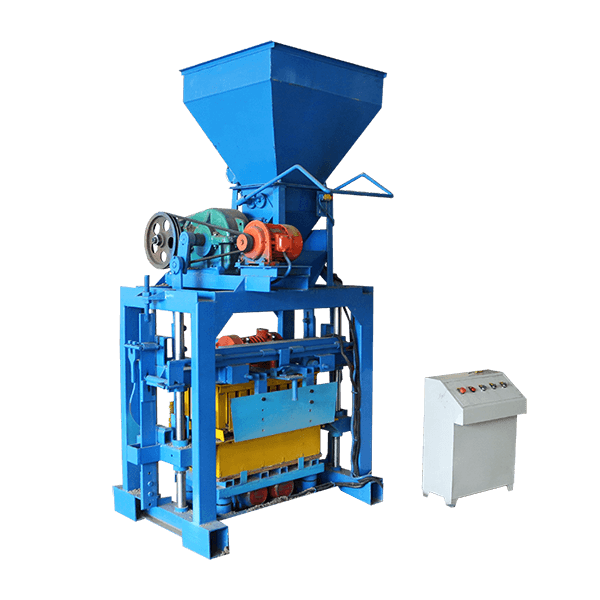

Paraments Of QT4-40 Manual Brick Making Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed area: 40㎡

Factory area :400㎡ Labor quantity :3 Machine power 10.4kw (Bottom Vibration Motor 3KW*2; Upper Vibration Motor 2.2KW; Mould lifting Motor: 2.2KW; ) Vibration force:30kn Reducer model: JZQ250 Diesel Generator Capacity: 30KVA Dimension: 1800*1450*1900mm Machine weight: 1200kg |

QT4-40 Manual Brick Making Machine Daily Production Capacity

| QT4-40 Manual Brick Making Machine Production Capacity | ||||||

| Size(LxWxH) (mm) | Photo | Forming Period (S) | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 |  |

40-50 | 3 | 216-270 | 1728-2160 |

| (2) | hollow block 400*200*200 |  |

35-45 | 4 | 288-360 | 2304-2880 |

| (3) | hollow block 400*150*200 |  |

35-45 | 5 | 360-450 | 2880-3600 |

| (4) | hollow block 400*100*200 |  |

35-45 | 7 | 504-630 | 4032-5040 |

| (5) | Solid Brick 240*50*115 |  |

35-45 | 18 | 1296-1620 | 10368-12960 |

| (6) | Porous Brick 240*115*90 |  |

35-45 | 9 | 648-810 | 5184-6408 |

| (7) | Curbstone 500*200*300 |  |

35-45 | 1 | 72-90 | 576-720 |

| (8) | “I” shape paver brick without color 200*163*60 |  |

35-45 | 6 | 432-540 | 3456-4320 |

| (9) | “S” Shape Paver Brick without color 225*112.5*60 |  |

35-45 | 9 | 648-810 | 5184-6408 |

| (10) | Holland Brick without color 200*100*60 |  |

35-45 | 9 | 648-810 | 5184-6408 |

| (11) | Square Paver wihtout color 250*250*60 |  |

35-45 | 3 | 216-270 | 1728-2160 |

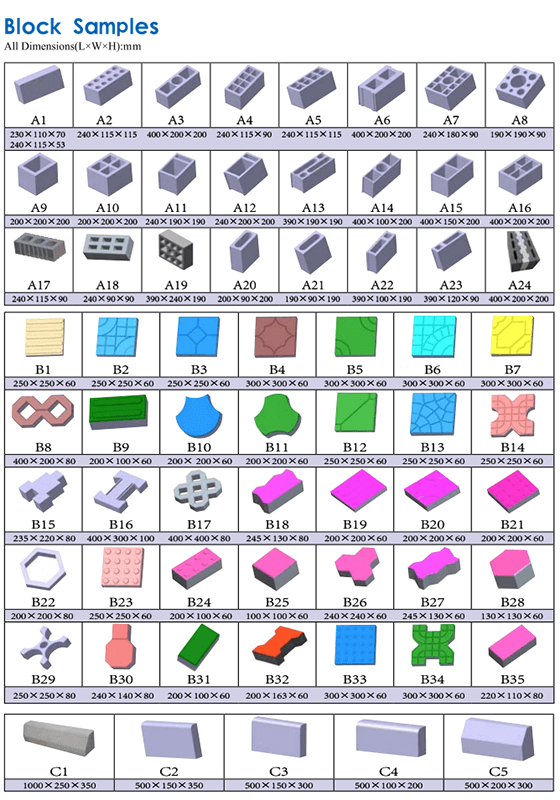

QT4-40 Manual Brick Making Machine- Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT4-40 Manual Brick Making Machine-Full Production Line

1. How many workers are required for operating this block machine?

A total of 4 workers are needed to efficiently operate the QT4-40 manual block machine:

- 1 worker is responsible for loading raw materials into the concrete mixer, either with a wheelbarrow or a small wheel loader.

- 1 worker operates the main brick machine.

- 2 workers carry the freshly produced blocks to the curing area.

2. What types of blocks can be produced with the QT4-40 brick machine?

The QT4-40 manual block machine is versatile and can produce a variety of blocks and bricks in different sizes and shapes by simply switching the molds. These include hollow blocks, solid bricks, interlocking blocks, and curbstones. However, it cannot produce colored paver bricks, as it does not come with a color-feeding device.

3. How should the QT4-40 manual block machine be maintained?

This machine is low-maintenance. For optimal performance and longevity:

- Clean the concrete mixer and block molds after each day’s work.

- Regularly check and tighten bolts and nuts to ensure they are secure.

- Apply lubricating oil to any moving or friction-prone parts.

4. What is the delivery time for the QT4-40 block-making machine?

The typical delivery time for the QT4-40 block machine is around 20 days from the date of deposit payment.

Working Videos

1. How many workers are required for operating this block machine?

A total of 4 workers are needed to efficiently operate the QT4-40 manual block machine:

- 1 worker is responsible for loading raw materials into the concrete mixer, either with a wheelbarrow or a small wheel loader.

- 1 worker operates the main brick machine.

- 2 workers carry the freshly produced blocks to the curing area.

2. What types of blocks can be produced with the QT4-40 brick machine?

The QT4-40 manual block machine is versatile and can produce a variety of blocks and bricks in different sizes and shapes by simply switching the molds. These include hollow blocks, solid bricks, interlocking blocks, and curbstones. However, it cannot produce colored paver bricks, as it does not come with a color-feeding device.

3. How should the QT4-40 manual block machine be maintained?

This machine is low-maintenance. For optimal performance and longevity:

- Clean the concrete mixer and block molds after each day’s work.

- Regularly check and tighten bolts and nuts to ensure they are secure.

- Apply lubricating oil to any moving or friction-prone parts.

4. What is the delivery time for the QT4-40 block-making machine?

The typical delivery time for the QT4-40 block machine is around 20 days from the date of deposit payment.

Related Products

Related News

The QT4-35 manual brick making machine, also known as a manual block machine or manual brick moulding machine, is a […]

The construction industry is undergoing rapid transformation driven by technological advancements and innovative equipment that are reshaping how we design […]

The QT4-35 manual brick making machine, a popular choice for small to medium-sized construction projects, boasts an impressive lifespan when […]

The QT4-35 manual brick making machine, also known as the “Efficient Manual Block Forming Machine,” boasts an impressive production capacity […]

The maintenance cost and process for the QT4-35 manual brick making machine are relatively affordable and straightforward. Regular maintenance typically […]

The QT4-35 manual brick making machine offers numerous advantages for small to medium-sized construction projects. This versatile equipment combines cost-effectiveness with […]

The QT4-35 manual brick making machine is indeed easy to operate, making it an excellent choice for small to medium-sized construction […]

The QT4-35 manual brick making machine, also known as the “Efficient Manual Block Forming Machine,” is a versatile and cost-effective […]