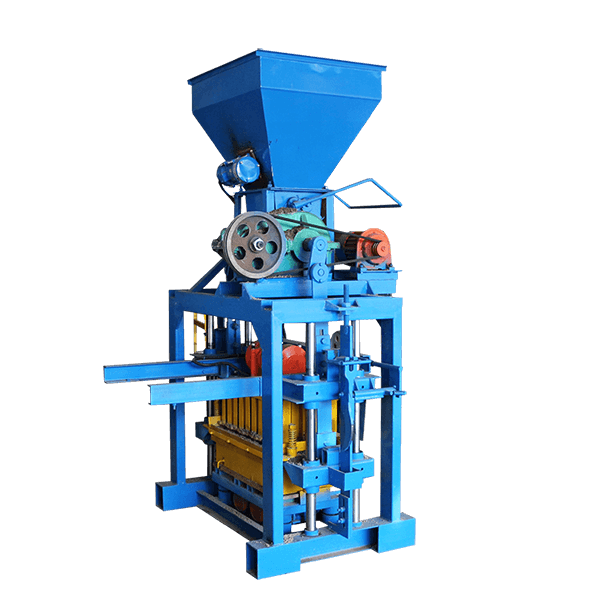

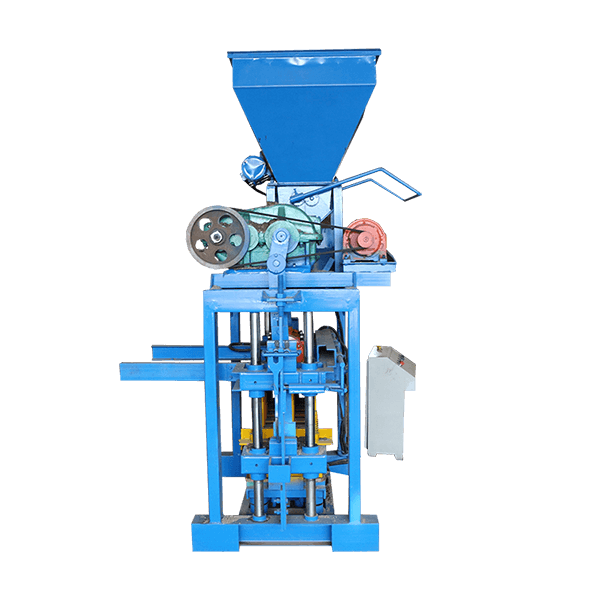

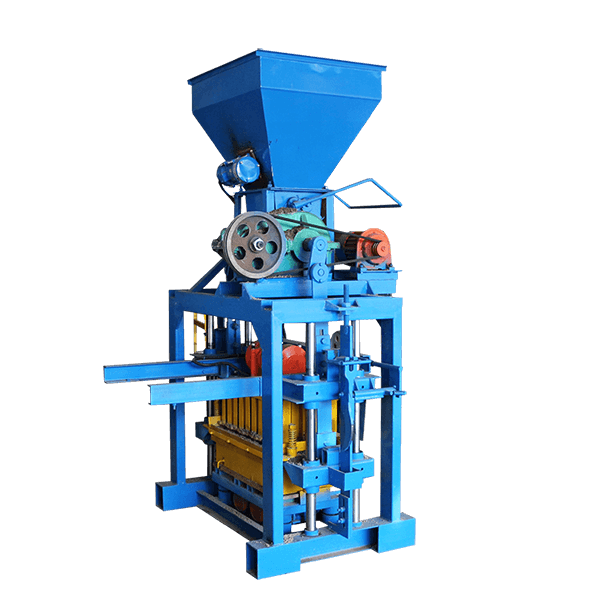

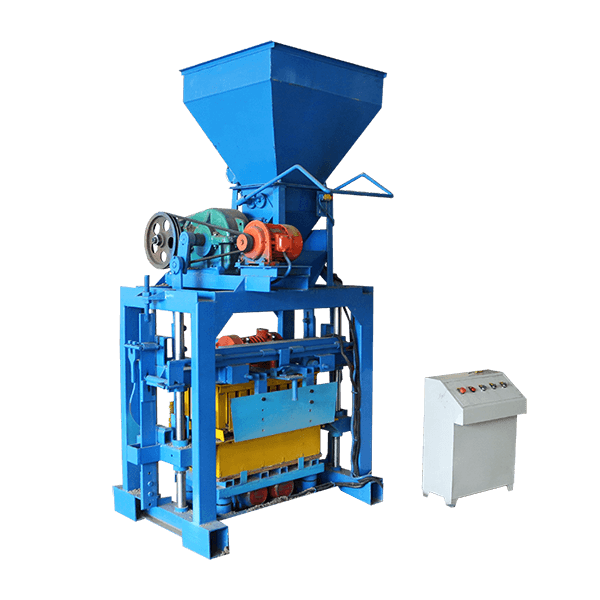

QT4-35 Manual Brick Making Machine

The QT4-35 Manual Brick Making Machine is a cost-effective, versatile solution for producing various block types, including hollow blocks, paver bricks, and curbstones, ideal for small to medium-scale projects.

Introduction Of QT4-35 Manual Brick Making Machine

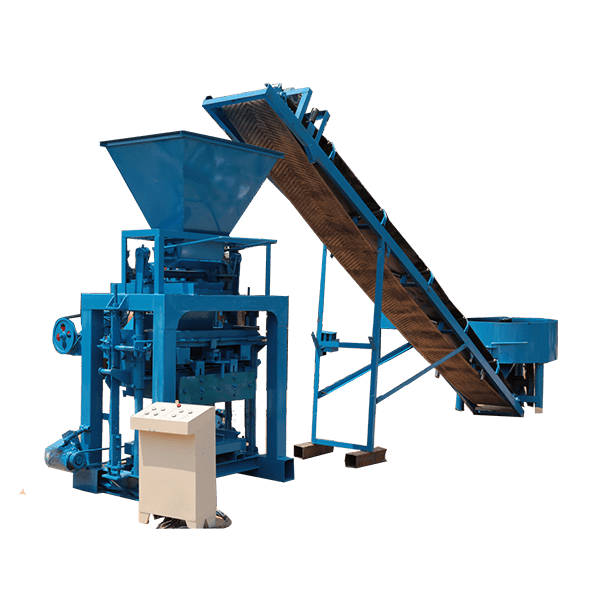

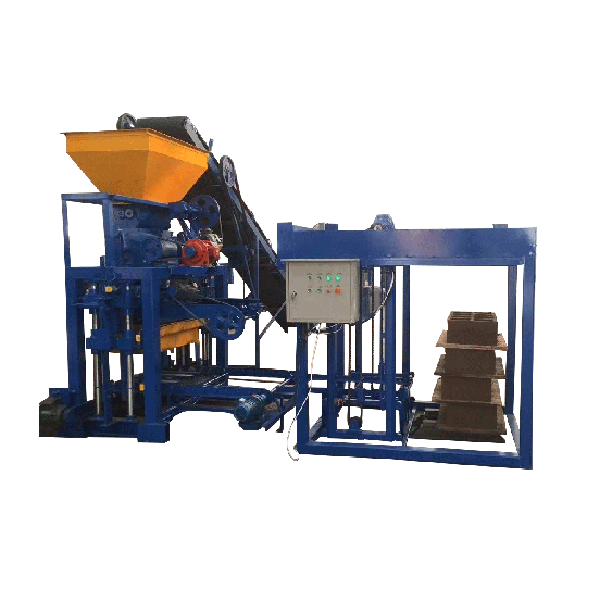

The QT4-35 Manual Brick Making Machine by Raytone is designed for flexibility and simplicity, aimed at boosting productivity while minimizing labor costs. This manual brick machine, with an added raw materials hopper, can produce a wide range of block types, including hollow blocks, pavers, and curbstones.

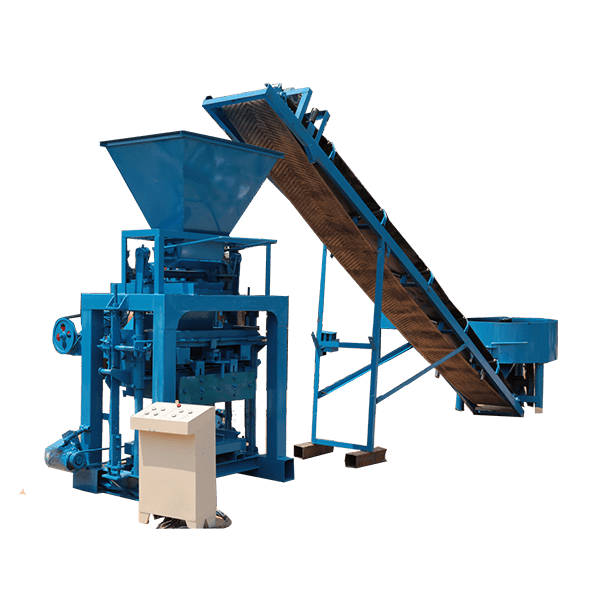

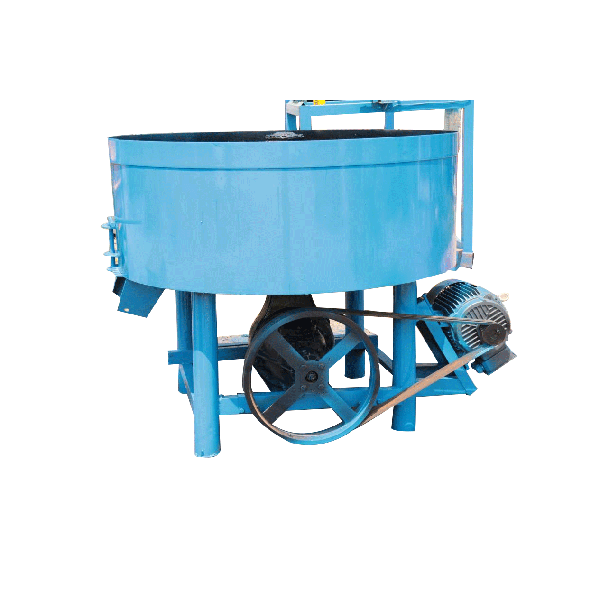

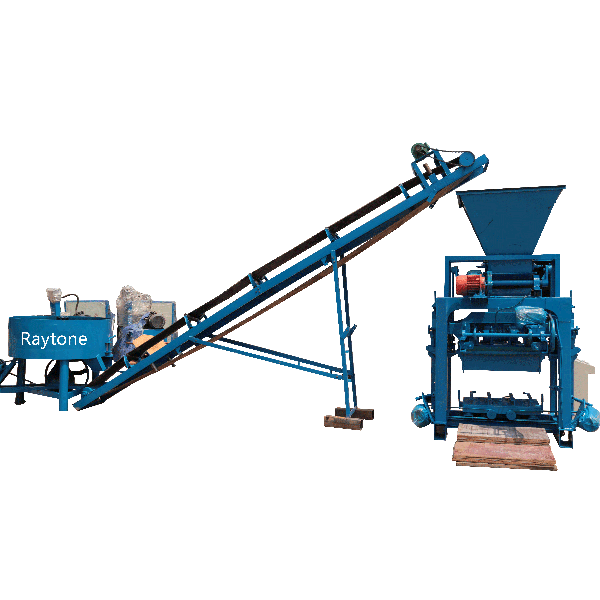

Equipped with a JQ350 concrete mixer and a 6-meter belt conveyor, the QT4-35 streamlines material handling and mixing, enhancing efficiency and output. Its design features an electric push-pulling system for top mold control, which helps increase production precision and reduces manual effort.

With a daily capacity of 2,560-3,290 eight-inch hollow blocks, the QT4-35 is particularly suited for developing markets where simplicity, affordability, and durability are prioritized.

This machine line also includes high-quality block trolleys and an option for a GMT brick pallet, further extending its reliability and lifespan. Raytone offers customizations, allowing the QT4-35 to meet various client needs while remaining a budget-friendly option for scaling up block production.

Advantages of the QT4-35 Manual Brick Making Machine

1. Cost-Effective Solution:

The QT4-35 offers an affordable entry point for small to medium producers, providing advanced features at a budget-friendly price, particularly suited for emerging markets.

2. Ease of Installation and Low Maintenance:

With minimal setup required and fewer moving parts, the QT4-35 reduces installation time and ongoing maintenance costs, supporting sustained, reliable production.

3. High Output with Low Labor Requirements:

This machine’s integrated hopper and conveyor allow it to operate efficiently with only three workers, saving on labor while maintaining a daily output of up to 3,290 blocks.

4. Long-Lasting Performance:

Optional upgrades like the GMT brick pallet, reinforced inner mixer plates, and anti-wear bushes enhance the QT4-35’s durability, making it a solid investment for long-term use.

Get Free Quote of QT4-35 Manual Brick Making Machine

QT4-35 Manual Brick Making Machine Overview

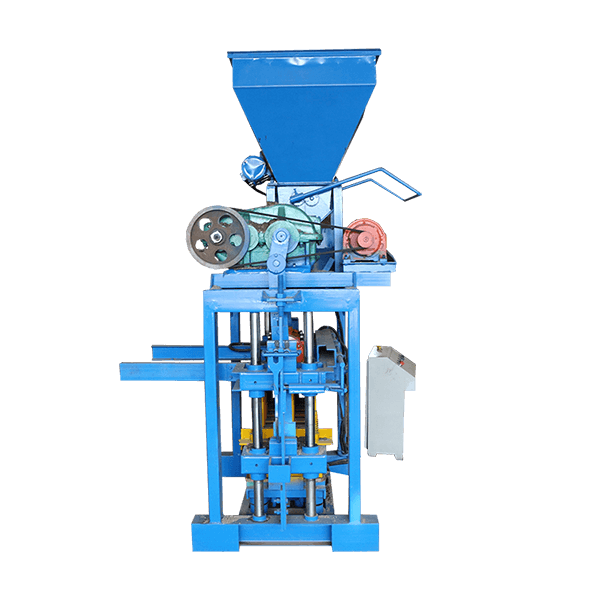

The QT4-35 manual brick machine features a simple design with a raw materials hopper to save labor and improve efficiency. It can produce various hollow blocks, paver bricks, and curbstones using cement, sand, and crushed stones.This model, also known as QT40-1 manual block machine, offers customized molds to meet client-specific requirements.

- Production Capacity: 8-inch Hollow Blocks: 2,560-3,290 pieces per 8-hour shift.

- Price Range: $5,000 to $15,000 USD, depending on the number of molds.

1. Simple Machine Design: Built with a straightforward structure and a raw materials hopper, the QT4-35 is easy to operate and maintain, making it ideal for small to medium production lines with minimal setup.

2. Versatile Block Molds: The QT4-35 accommodates a range of mold sizes and types, allowing users to produce various products such as hollow blocks, pavers, and curbstones, all tailored to local demand.

3. Enhanced Mixing and Conveyor System: Equipped with a JQ350 concrete mixer and a 6-meter belt conveyor, the QT4-35 ensures even material blending and smooth feeding, boosting the machine’s productivity and output.

QT4-35 Manual Brick Making Machine Basic Requirements for Production Start

| Land area | 200 Square Meters | Water Consumption | 1.8 T/day |

| Workshop area | 40 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 18.7KW*8 Hours=149.6 KWH; |

| Cement Consumption | 5.35 Tons per day | Sand consumption | 21.7 tons per day |

| Crushed stones consumption | 27 tons per day |

Detailed Introduction of QT4-35 Manual Brick Making Machine Line

| Number | Item | Function |

| 1 | JQ350 Concrete mixer | Mix raw material including cement, sand, stone |

| 2 | 6M Belt Conveyor | Carry mixed material from mixer to Block machine |

| 3 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 4 | Manual Trolley | Transport the produced blocks to curing area |

Paraments Of QT4-35 Manual Brick Making Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area:40 square meters

Factory area:400 square meters Labor quantity:3 Machine power:10.4kw Vibration force:30kn Reducer model: JZQ250 Diesel Generator Capacity: 30KVA Machine size: 1800*1500*2500mm Machine weight: 1500kg |

QT4-35 Manual Brick Making Machine Daily Production Capacity

| QT4-35 Manual Brick Making Machine Production Capacity | ||||||

| Size(LxWxH) (mm) | Photo | Forming Period (S) | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 |  |

35-45 | 3 | 240-308 | 1920-2468 |

| (2) | hollow block 400*200*200 |  |

35-45 | 4 | 320-410 | 2560-3290 |

| (3) | hollow block 400*150*200 |  |

35-45 | 5 | 400-514 | 3200-4114 |

| (4) | hollow block 400*100*200 |  |

35-45 | 7 | 560-720 | 4480-5760 |

| (5) | Solid Brick 240*50*115 |  |

35-45 | 18 | 1440-1848 | 11520-14784 |

| (6) | Porous Brick 240*115*90 |  |

35-45 | 9 | 720-924 | 5760-7392 |

| (7) | Curbstone 500*200*300 |  |

35-45 | 1 | 80-102 | 640-816 |

| (8) | “I” shape paver brick without color 200*163*60 |  |

35-45 | 6 | 480-616 | 3840-4928 |

| (9) | “S” Shape Paver Brick without color 225*112.5*60 |  |

35-45 | 9 | 720-924 | 5760-7392 |

| (10) | Holland Brick without color 200*100*60 |  |

35-45 | 9 | 720-924 | 5760-7392 |

| (11) | Square Paver without color 250*250*60 |  |

35-45 | 3 | 240-308 | 1920-2468 |

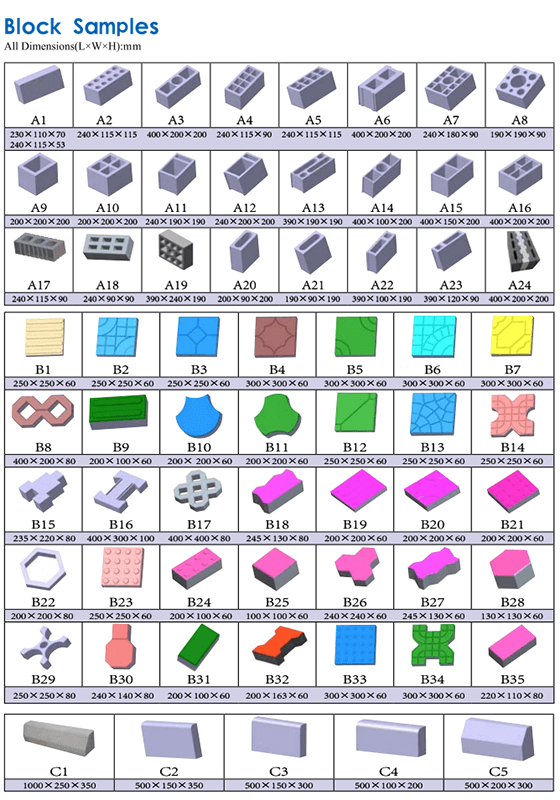

QT4-35 Manual Brick Making Machine- Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT4-35 Manual Brick Making Machine-Full Production Line

1. What is the packing method?

For container loading, we use a safe nude packing method inside the container. For LCL shipments, we can pack the machine in a wooden case or steel box for added protection, though additional costs apply.

2. How many workers are required for the QT4-35 manual block machine?

The QT4-35 machine requires 4-5 workers: one to operate the mixer and feed materials, one to operate the main machine, and two for transporting blocks. The layout of the office, curing area, and stacking area can be customized to suit your setup.

3. What brand of motor and electrical components are used?

RAYTONE primarily uses high-quality copper motors from reputable Chinese brands like HUAXING or SHANBO. For an extra cost, Siemens brand motors are also available upon request.

4. What type of steel is used for the machine and molds?

RAYTONE uses Q235B steel for the machine body and manganese steel for the molds, ensuring durability and longevity.

5. Will you provide on-site installation services?

Yes, we offer technical support with a team of service technicians available to assist with installation as needed.

6. Are spare parts included with the machine?

Yes, we include a set of spare parts with each machine, which are designed to last over two years.

7. Is there technical support available after purchase?

Absolutely, we offer 24-hour online technical support to assist you during production.

8. What is the warranty period for the machine?

The QT4-35 machine comes with a 1-year warranty, excluding parts subject to normal wear and tear.

Working Videos

1. What is the packing method?

For container loading, we use a safe nude packing method inside the container. For LCL shipments, we can pack the machine in a wooden case or steel box for added protection, though additional costs apply.

2. How many workers are required for the QT4-35 manual block machine?

The QT4-35 machine requires 4-5 workers: one to operate the mixer and feed materials, one to operate the main machine, and two for transporting blocks. The layout of the office, curing area, and stacking area can be customized to suit your setup.

3. What brand of motor and electrical components are used?

RAYTONE primarily uses high-quality copper motors from reputable Chinese brands like HUAXING or SHANBO. For an extra cost, Siemens brand motors are also available upon request.

4. What type of steel is used for the machine and molds?

RAYTONE uses Q235B steel for the machine body and manganese steel for the molds, ensuring durability and longevity.

5. Will you provide on-site installation services?

Yes, we offer technical support with a team of service technicians available to assist with installation as needed.

6. Are spare parts included with the machine?

Yes, we include a set of spare parts with each machine, which are designed to last over two years.

7. Is there technical support available after purchase?

Absolutely, we offer 24-hour online technical support to assist you during production.

8. What is the warranty period for the machine?

The QT4-35 machine comes with a 1-year warranty, excluding parts subject to normal wear and tear.

Related Products

Related News

The QT4-35 manual brick making machine, also known as a manual block machine or manual brick moulding machine, is a […]

The QT4-35 manual brick making machine is a versatile and cost-effective solution for small to medium-sized construction projects. This manual block […]

The QT4-35 manual brick making machine, a popular choice for small to medium-sized construction projects, boasts an impressive lifespan when […]

The QT4-35 manual brick making machine, also known as the “Efficient Manual Block Forming Machine,” boasts an impressive production capacity […]

The maintenance cost and process for the QT4-35 manual brick making machine are relatively affordable and straightforward. Regular maintenance typically […]

The QT4-35 manual brick making machine offers numerous advantages for small to medium-sized construction projects. This versatile equipment combines cost-effectiveness with […]

The QT4-35 manual brick making machine is indeed easy to operate, making it an excellent choice for small to medium-sized construction […]

The QT4-35 manual brick making machine, also known as the “Efficient Manual Block Forming Machine,” is a versatile and cost-effective […]