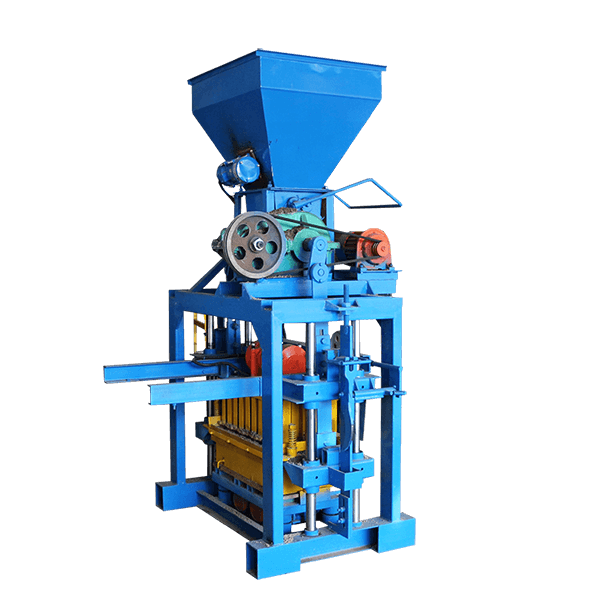

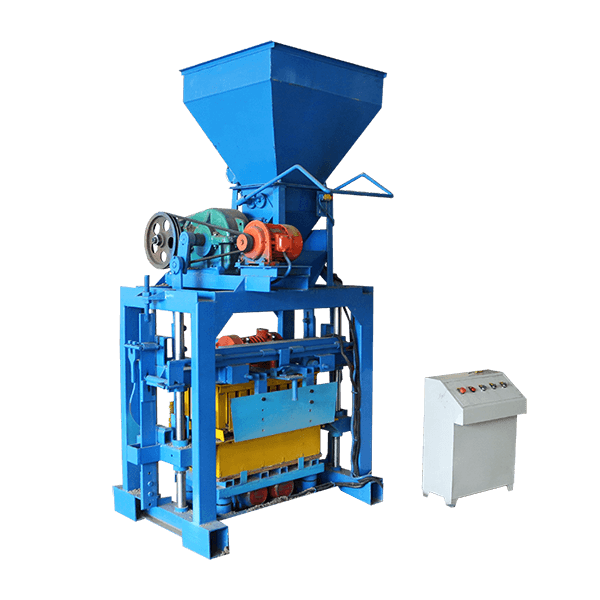

QT4-28 Semi-Automatic Hollow Block Making Machine

The QT4-28 Hollow Block Making Machine is a semi-automatic, easy-to-operate, and efficient solution for medium-scale block production, providing high productivity and low investment.

Introduction Of QT4-28 Semi-Automatic Hollow Block Making Machine

The QT4-28 Hollow Block Making Machine is a powerful upgrade from the QT4-40 Manual Block Machine, designed to enhance efficiency in block production for medium-scale projects. Equipped with a hopper and compatible with a belt conveyor system, this hollow block machine allows for smooth and automatic raw material feeding into the hopper, reducing manual labor and boosting productivity. One of its standout features is the advanced PLC control, which offers near-fully automatic operation—just a single button press forms a block, earning it the nickname “One Button Block Forming Machine.”

Ideal for both commercial and industrial brick production, the QT4-28 block making machine operates with vibration motors, ensuring solid and well-formed blocks every time. This hollow block machine model is economically priced, ranging from $7,900 to $12,000 USD, making it an accessible choice for developing markets seeking an efficient yet affordable semi-automatic brick-making machine.

With a daily production capacity of up to 4,114 pieces of 8-inch hollow blocks, the QT4-28 is ideal for projects that demand high productivity with low operating costs. Designed to simplify setup and reduce labor, this hollow block machine meets the demands of concrete block production for medium-sized projects and stands out as a cost-effective investment in semi-automatic block production equipment.

Advantages of the QT4-28 Semi-Automatic Hollow Block Making Machine

1. Easy Installation and Operation:

The QT4-28 Hollow Block Making Machine is user-friendly, requiring only a simple belt conveyor setup and power connection to start. This ease of installation minimizes downtime, making it ideal for quick deployment and immediate use in various brick and block production settings.

2. Low Investment, High Value:

With a highly competitive price, the QT4-28 offers exceptional value for medium-scale block manufacturers. It provides a cost-effective alternative to pricier automatic models like the QT4-25 and QT4-18, making it a smart investment for growing businesses in developing markets.

3. Streamlined, Durable Design:

The QT4-28 features a simple, robust structure without complex pallet-feeding or block-conveying sections. Pallets are fed manually, and finished blocks are removed via trolley, reducing the risk of mechanical issues and allowing for low-maintenance, continuous production in challenging environments.

4. Optimized for Medium-Scale Projects:

Specially tailored for medium-scale block production, the QT4-28 is semi-automatic with automatic feeding, distribution, and forming. Its efficiency, simplicity, and affordability make it particularly popular in developing countries seeking economical and reliable hollow block and paver production solutions.

Get Free Quote of QT4-28 Semi-Automatic Hollow Block Making Machine

QT4-28 Semi-Automatic Block Machine Overview

The QT4-28 machine is an upgrade from the QT4-40 manual model. With the addition of a hopper and raw material distribution device, it improves production efficiency and reduces labor requirements. The machine is operated semi-automatically with a one-button block forming system and vibration motors.

- Production Capacity: 8-inch Hollow Blocks: Up to 4,114 pieces per 8-hour shift.

- Price Range: $7,900 to $12,000 USD.

1. Automatic Raw Material Feeding System:

The QT4-28 Hollow Block Making Machine comes equipped with a hopper that integrates seamlessly with a belt conveyor for automatic and efficient raw material delivery. This feature minimizes manual input, ensuring a continuous flow of materials for higher production efficiency. The automatic feeding system supports faster concrete block and hollow brick formation, making it ideal for medium-scale brick production.

2. One-Button Operation for Easy Use:

Controlled by an advanced PLC system, the QT4-28 offers a unique “one-button block forming” process, making it highly user-friendly and accessible for both beginners and experienced block manufacturers. This semi-automatic feature enables the operator to produce blocks with just one press, leading the machine to be known as the “One Button Block Forming Machine.” This is perfect for hollow block and cement brick production lines needing high efficiency.

3. High-Efficiency Vibration Forming Technology:

Equipped with vibration motors, the QT4-28 ensures concrete is evenly distributed within the mold, creating durable and high-density blocks. This vibration technology allows for the production of high-quality 8-inch hollow blocks, making it an excellent choice for medium-sized concrete block and hollow brick projects.

4. Compact Design, Easy to Maintain:

The QT4-28 Hollow Block Making Machine features a simple structure with no complex pallet feeding or block conveying components. Operators only need to feed pallets manually and use a hand trolley to remove finished blocks, making it ideal for start-up or small- to medium-sized brick manufacturing plants. Designed to meet the needs of developing markets, this machine offers easy installation and maintenance, making it a cost-effective investment for cement block and paver production.

QT4-28 Semi-Automatic Hollow Block Making Machine Basic Requirements for Production Start

| Land area | 300 Square Meters | Water Consumption | 2.4 T/day |

| Workshop area | 30 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V;50HZ/60HZ |

| Labors Quantity | 3 workers | Power Consumption | 26.5 KW*8 Hours=212 KWH; |

| Cement Consumption | 7.05 Tons per day | Sand consumption | 28.5 tons per day |

| Crushed stones consumption | 35.55 tons per day |

Detailed Introduction of QT4-28 Semi-Automatic Hollow Block Making Machine Line

| Number | Item | Function |

| 1 | JQ500 Concrete mixer | Mix raw material including cement, sand, stone |

| 2 | 6M Belt Conveyor | Carry mixed material from mixer to Block machine |

| 3 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 4 | Manual Trolley | Transport the produced blocks to curing area |

Paraments Of QT4-28 Semi-Automatic Hollow Block Making Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area:60 square meters

Factory area:600 square meters Labor quantity;4 Machine power:13.45kw Vibration force :50kn Reducer model: JZQ250 Diesel Generator Capacity: 30KVA Machine size: 2600*2000*2000mm Machine weight: 3200kg |

QT4-28 Semi-Automatic Hollow Block Making Machine Daily Production Capacity

| QT4-28 Block Machine Theoretical production capacity | ||||||

| Size(L*W*H) (mm) | Photo | Forming Period (S) | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 |  |

28 | 3 | 386 | 3086 |

| (2) | hollow block 400*200*200 |  |

28 | 4 | 514 | 4114 |

| (3) | hollow block 400*150*200 |  |

28 | 4 | 514 | 4114 |

| (4) | hollow block 400*100*200 |  |

28 | 7 | 900 | 7200 |

| (5) | Solid Brick 240*50*115 |  |

28 | 18 | 2314 | 18514 |

| (6) | Porous Brick 240*115*90 |  |

28 | 9 | 1157 | 9257 |

| (7) | Curbstone 500*200*300 |  |

28 | 1 | 129 | 1029 |

| (8) | “I” shape paver brick without color 200*163*60 |  |

28 | 6 | 771 | 6171 |

| (9) | “S” Shape Paver Brick without color 225*112.5*60 |  |

28 | 9 | 1157 | 9257 |

| (10) | Holland Brick without color 200*100*60 |  |

28 | 9 | 1157 | 9257 |

| (11) | Square Paver wihtout color 250*250*60 |  |

28 | 3 | 386 | 3086 |

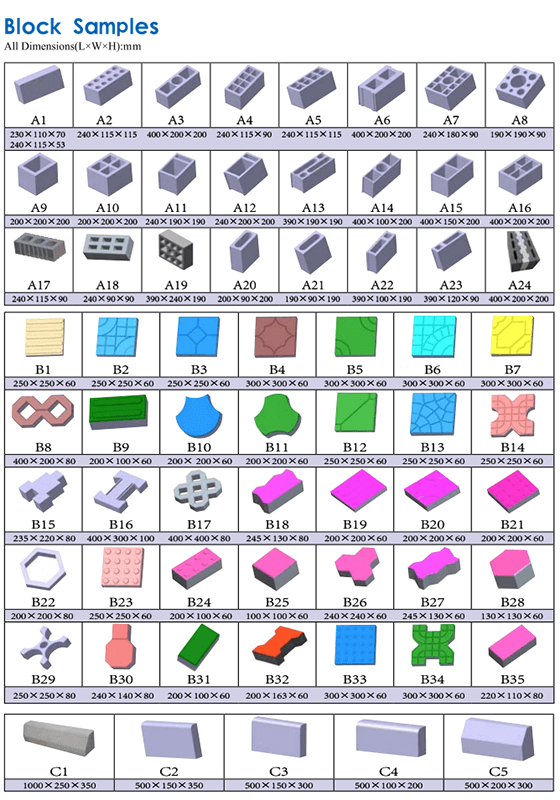

QT4-28 Semi-Automatic Hollow Block Making Machine - Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT4-28 Semi-Automatic Hollow Block Making Machine Full Production Line

1. Can the QT4-28 Hollow Block Making Machine produce other types of paver and interlocking bricks?

Yes, the QT4-28 machine can manufacture a variety of brick shapes and sizes when equipped with different molds, allowing for versatility in block production.

2. What raw materials and mix ratios are required for producing concrete blocks with the QT4-28 machine?

This machine uses materials like cement, concrete, sand, fly ash, construction waste, coal gangue, slag, and mountain powder. The recommended mix ratio is approximately 8-10% cement, 30-40% sand, and 50-60% stone, with a general formula of cement:sandat 1:4:5.

3. What is the standard weight for hollow blocks?

The typical weight for hollow blocks is as follows: an 8-inch (400×200×200 mm) block weighs 17 kg, a 6-inch (400×150×200 mm) block weighs 13.5 kg, and a 4-inch (400×100×200 mm) block weighs 10 kg.

Working Videos

1. Can the QT4-28 Hollow Block Making Machine produce other types of paver and interlocking bricks?

Yes, the QT4-28 machine can manufacture a variety of brick shapes and sizes when equipped with different molds, allowing for versatility in block production.

2. What raw materials and mix ratios are required for producing concrete blocks with the QT4-28 machine?

This machine uses materials like cement, concrete, sand, fly ash, construction waste, coal gangue, slag, and mountain powder. The recommended mix ratio is approximately 8-10% cement, 30-40% sand, and 50-60% stone, with a general formula of cement:sandat 1:4:5.

3. What is the standard weight for hollow blocks?

The typical weight for hollow blocks is as follows: an 8-inch (400×200×200 mm) block weighs 17 kg, a 6-inch (400×150×200 mm) block weighs 13.5 kg, and a 4-inch (400×100×200 mm) block weighs 10 kg.

Related Products

Related News

The QT4-35 manual brick making machine, also known as a manual block machine or manual brick moulding machine, is a […]

Investment in Senegal’s Construction Industry Senegal’s construction sector continues to expand, attracting investors looking to capitalize on the growing demand […]

The QT4-35 manual brick making machine, a popular choice for small to medium-sized construction projects, boasts an impressive lifespan when […]

The maintenance cost and process for the QT4-35 manual brick making machine are relatively affordable and straightforward. Regular maintenance typically […]

The QT4-35 manual brick making machine, also known as the “Efficient Manual Block Forming Machine,” is a versatile and cost-effective […]

In January 2018, Raytone Company successfully delivered a QT4-28 block making machine to Uruguay, marking another milestone in our global […]

The construction industry in Botswana is booming, and with it, the demand for high-quality concrete blocks is rising. Among the […]

The construction industry in Mozambique is growing rapidly, and as demand for durable and cost-effective building materials increases, the need […]