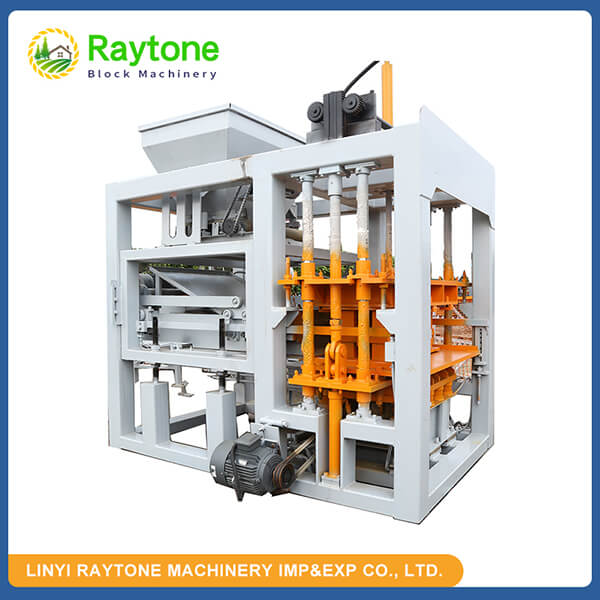

QT4-18 Automatic Hydraulic Concrete Block Making Machine

The QT4-18 is a compact, automatic hydraulic block machine producing various blocks, including color pavers, making it ideal for small to mid-sized investors.

Introduction Of QT4-18 Automatic Hydraulic Concrete Block Making Machine

The QT4-18 Automatic Hydraulic Concrete Block Making Machine is a versatile, compact, and high-performing hydraulic block-making machine that is popular for producing a wide range of concrete blocks, including standard hollow blocks, solid blocks, and color paver bricks.

The QT4-18 is an affordable option well-suited to small and medium-sized investors seeking to establish a concrete block production line. The machine’s changeable molds allow for flexible block production, enabling the creation of custom sizes and shapes.

The machine is capable of producing up to 6,400 pieces of 8-inch hollow blocks per 8-hour shift, making it an optimal choice for those looking to start or expand a concrete block business with a reliable quality and ease of operation.

Advantages of the QT4-18 Automatic Hydraulic Concrete Block Making Machine

1. Compact Design & Cost-Effective

The QT4-18 Automatic Hydraulic Concrete Block Making Machine offers a cost-effective solution for concrete block manufacturing, making it an ideal choice for small and medium-sized concrete block factories entering the block production industry.

2. Efficient Production with High Output

The QT4-18 Automatic Hydraulic Concrete Block Making Machine has been designed to maximize block production, allowing the manufacturing of a wide variety of concrete blocks, including hollow blocks, solid blocks, and color pavers, all under different molds. This flexibility makes it an ideal choice for a hollow block machine line or other custom block production needs.

3. Advanced Hydraulic & Vibration System

This machine’s hydraulic model provides precision control and efficient energy use, while its advanced vibration system ensures uniform block quality and longevity of the mold, which are essential for high-performance brick-making machinery.

4. User-Friendly PLC Control System

The QT4-18 Automatic Hydraulic Concrete Block Making Machine features a PLC control panel with an intuitive interface, allowing operators to manage each step of the production process with ease. This is an optimal choice for investors seeking to streamline their automated concrete block production line.

Get Free Quote of QT4-18 Automatic Hydraulic Concrete Block Making Machine

QT4-18 Automatic Block Making Machine Overview

The QT4-18 automatic block making machine is a best-selling model with simple yet automatic operation. It is cost effective, ideal for small to medium investors starting a concrete block factory. It produces a variety of blocks and bricks with interchangeable molds.

- Production Capacity: 8-inch hollow blocks: Up to 6,400 per 8-hour shift.

- Price Range: $16,100 to $29,300 USD, depending on number of molds and brick pallets.

1. Robust Steel Frame & Guide Pillars

The QT4-18 Automatic Concrete hollow block Making Machine’s durable, high-strength steel frame and reinforced guide pillars guarantee stability and precision for long-term concrete block production, particularly in standard brick and hollow brick factories.

2. Efficient Material Distribution System

The QT4-18 Automatic Concrete hollow block Making Machine’s material distribution system, featuring separate raw material storage and distribution, enhances efficiency, streamlining the production process. This machine is well-suited for producing thin-wall and multi-row porous blocks, as well as common building bricks.

3. Reliable Motors & Power System

The QT4-18 Automatic Concrete hollow block Making Machine’s power system is equipped with top-brand motors and optional Siemens upgrades, guaranteeing reliability and a long machine lifespan. This is an important feature for companies looking to maintain consistent output in their brick manufacturing line.

4. Durable Mould System

The high-temperature heat treatment of the moulds ensures durability and a longer lifespan, while the precise demoulding system helps maintain consistent block quality, which is especially valuable for investors in the construction block-making sector.

QT4-18 Automatic Hydraulic Concrete Block Machine Line Basic Requirements for Production Start

| Land area | 1200 Square Meters | Water Consumption | 4 T/day |

| Workshop area | 100 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V; 50HZ/60HZ |

| Labors Quantity | 6 workers | Power Consumption | 35.85KW*8 Hours= 286.8KWH; |

| Cement Consumption | 10.5 Tons per day | Sand consumption | 42 tons per day |

| Crushed stones consumption | 52 tons per day |

Detailed Introduction of QT4-18 Automatic Hydraulic Concrete Block Making Machine Line

| Number | Item | Function |

| 1 | JQ500 Concrete mixer | Mix raw material including cement, sand, stone |

| 2 | 6M Belt Conveyor | Carry mixed material from mixer to Block machine |

| 3 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 4 | Single Row Block Stacker Machine | Stack the finished hollow blocks to several layers |

| 5 | Manual Trolley | Transport the produced blocks to curing area |

Paraments Of QT4-18 Automatic Hydraulic Concrete Block Making Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area :100 square meters

Factory area:1200 square meters Labor quantity:4 Machine power:25kw Vibration force:50-65 KN Moulding Period:15-20 S Diesel Generator Capacity: 50KVA Machine size: 3740×2250×2450mm Machine weight: 4000kg |

QT4-18 Automatic Hydraulic Concrete Block Making Machine Daily Production Capacity

| QT4-18 block machine theoretical production capacity | ||||||

| Size(LxWxH) (mm) | Forming Period (S) | Photo | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 | 18 |  |

3 | 600 | 4800 |

| (2) | hollow block 400*200*200 | 18 |  |

4 | 800 | 6400 |

| (3) | hollow block 400*150*200 | 18 |  |

5 | 1000 | 8000 |

| (4) | hollow block 400*100*200 | 18 |  |

7 | 1400 | 11200 |

| (5) | Solid Brick 240*53*115 | 18 |  |

26 | 5200 | 41600 |

| (6) | Porous Brick 240*115*90 | 18 |  |

12 | 2400 | 19200 |

| (7) | Curbstone 500*200*300 | 18 |  |

2 | 400 | 3200 |

| (8) | “I” shape paver brick 200*163*60 | 25 |  |

8 | 1152 | 9216 |

| (9) | “S” Shape Paver Brick 225*112.5*60 | 25 |  |

12 | 1728 | 13824 |

| (10) | Holland Brick 200*100*60 | 25 |  |

14 | 2016 | 16126 |

| (11) | Square Paver 250*250*60 | 25 |  |

3 | 432 | 3456 |

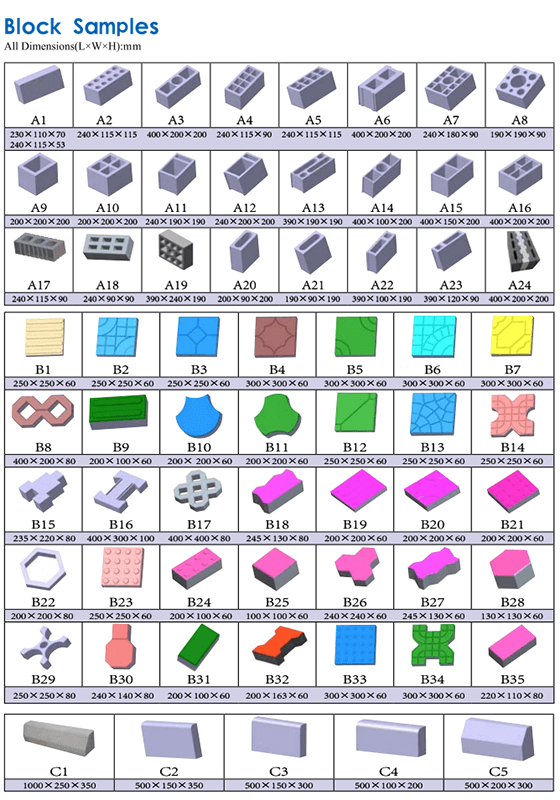

QT4-18 Automatic Hydraulic Concrete Block Making Machine - Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT4-18 Automatic Hydraulic Concrete Block Making Machine Full Production Line

1. How to Select the Right Block Machine?

- By Productivity: Tell us the block size and daily output you need, and we’ll recommend the best machine model.

- By Budget: Share your budget, and we’ll suggest models within your price range.

2. What’s the Raw Material Formula?

Common mix: 10% cement, 40% sand, 50% stone, 5% water per 100kg. Exact formulas can vary—contact us for more details.

Daily Raw Material Consumption for QT4-18

To produce 6,400 pieces of 8-inch hollow blocks, you’ll need approximately 42 tons of sand, 52 tons of stones, 10 tons of cement, and 4 tons of water.

3. When Can Finished Blocks Be Removed from Pallets?

Blocks can typically be removed from pallets after 18-24 hours, though in hot climates, they may be removed sooner once dry.

How to Cure Blocks

- Natural Curing: Stack blocks and water them 3 times daily for 3-5 days, then reduce watering as needed. Steam Curing: For faster curing, steam rooms can reduce curing time to 9 hours.

- Typical Block Weight

- Standard 8-inch hollow block: 16.5 kg.

- Holland brick (200x100x60mm): 3.4 kg.

4. How to Maintain the Block Machine?

- Daily: Check bolts, nuts, and hydraulic hoses; tighten as needed.

- Weekly: Grease moving parts and lubricate the main cylinder. A maintenance manual is provided with each machine.

Working Videos

1. How to Select the Right Block Machine?

- By Productivity: Tell us the block size and daily output you need, and we’ll recommend the best machine model.

- By Budget: Share your budget, and we’ll suggest models within your price range.

2. What’s the Raw Material Formula?

Common mix: 10% cement, 40% sand, 50% stone, 5% water per 100kg. Exact formulas can vary—contact us for more details.

Daily Raw Material Consumption for QT4-18

To produce 6,400 pieces of 8-inch hollow blocks, you’ll need approximately 42 tons of sand, 52 tons of stones, 10 tons of cement, and 4 tons of water.

3. When Can Finished Blocks Be Removed from Pallets?

Blocks can typically be removed from pallets after 18-24 hours, though in hot climates, they may be removed sooner once dry.

How to Cure Blocks

- Natural Curing: Stack blocks and water them 3 times daily for 3-5 days, then reduce watering as needed. Steam Curing: For faster curing, steam rooms can reduce curing time to 9 hours.

- Typical Block Weight

- Standard 8-inch hollow block: 16.5 kg.

- Holland brick (200x100x60mm): 3.4 kg.

4. How to Maintain the Block Machine?

- Daily: Check bolts, nuts, and hydraulic hoses; tighten as needed.

- Weekly: Grease moving parts and lubricate the main cylinder. A maintenance manual is provided with each machine.

Related Products

Related News

The QT4-15 automatic brick making machine is a versatile and high-performance piece of equipment, ideal for producing a wide range of […]

The QT4-15 automatic brick making machine requires regular maintenance to ensure optimal performance and longevity. Key maintenance tasks include daily cleaning […]

If you’re in the construction industry or planning to invest in a reliable block-making solution, you’ve likely come across the […]

The QT4-15 automatic brick making machine represents a significant advancement in construction technology, offering a perfect blend of efficiency, versatility, and […]

Installing a QT4-15 automatic brick making machine typically takes between 3 to 5 days, depending on various factors such as site […]

The QT4-15 automatic brick making machine is a sophisticated piece of equipment designed for efficient and high-quality production of concrete blocks […]

Are you looking to master the operation of the QT4-15 automatic brick making machine? This robust equipment, designed for efficiency […]

The QT4-24 semi-automatic brick making machine is a versatile and reliable tool for producing high-quality bricks. This machine works well with […]