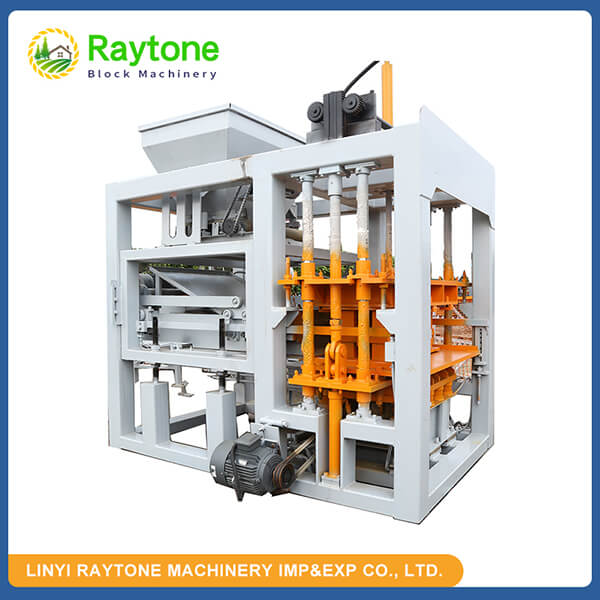

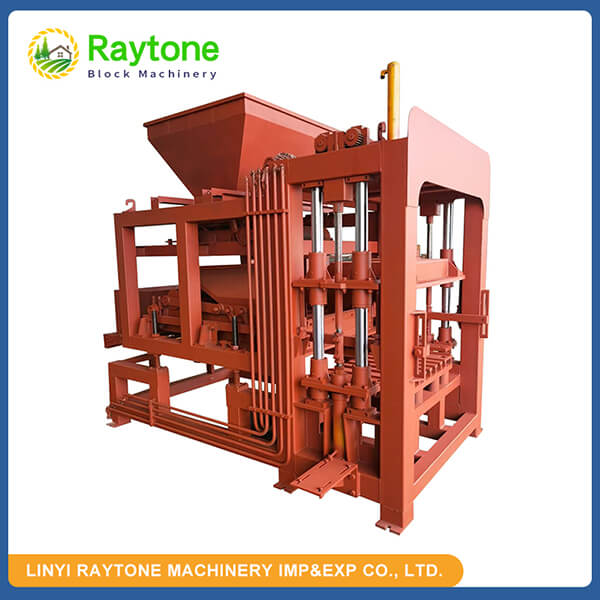

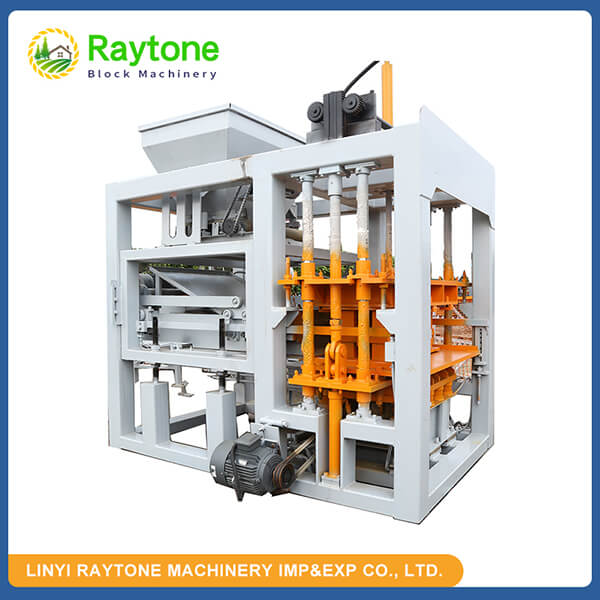

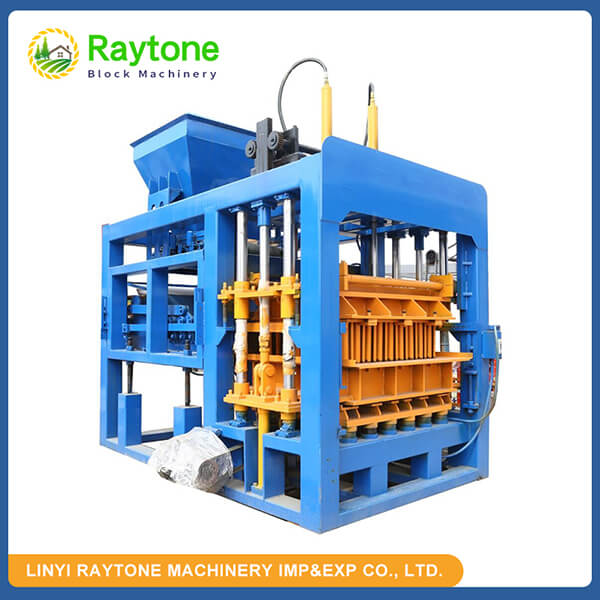

QT4-15 Automatic Concrete Hollow Block Making Machine

The QT4-15 Automatic Hollow Block Making Machine is an efficient, fully automated system for producing hollow blocks, pavers, and curbstones, with a capacity of 7,680 blocks per 8-hour shift.

- High Efficiency and Production:

- Consistent Quality:

- Adaptable for Various Raw Materials

- Easy Maintenance and Operation:

- Cost-Effective for Start-Up Factories

Introduction Of QT4-15 Automatic Concrete hollow block Making Machine:

QT4-15 automatic hollow block making machine is a highly sought-after model in the concrete block machinery industry. This machine is designed to produce a variety of hollow blocks, paving bricks, and curbstones using interchangeable molds. The QT4-15 hollow block machine is an optimal choice for small to medium-scale investors seeking to establish a concrete block manufacturing facility.

This fully automated hollow block production line offers the flexibility of changeable moulds, making it suitable for producing different block sizes, including 8-inch hollow blocks. The machine has a high production capacity of 7,680 pieces of 8-inch hollow blocks per 8-hour shift.

The price range for the QT4-15 automatic hollow block machine line is between $16,100 and $29,300, depending on the number of extra moulds and brick pallets included in the order. Please note that this price can vary based on customer specifications, such as mould customization, pallet options, and other add-ons.

Advantages of the QT4-15 Automatic Concrete hollow block Making Machine:

1. High Efficiency and Production:

The QT4-15 Automatic Concrete hollow block making machine’s flexible mould design and efficient production process allow it to meet diverse manufacturing needs, making it an ideal choice for both small- and medium-scale investors aiming to produce multiple brick types.

2. Consistent Quality:

The innovative vibrating table guarantees an even distribution of the exciting force, ensuring consistent material distribution across the mould and brick quality.

3. Adaptable for Various Raw Materials

The QT4-15 Automatic Concrete hollow block making machine is equipped with adjustable hydraulic pressure and flow, enabling it to handle a range of raw materials, including concrete, fly ash, and slag. This versatility makes it an ideal choice for regions with diverse material availability.

4. Easy Maintenance and Operation:

The QT4-15 Automatic Concrete hollow block making machine has been designed with ease of use in mind. It features a user-friendly interface and durable hydraulic components, which reduce maintenance needs and downtime, maximising production time.

5. Cost-Effective for Start-Up Factories

The QT4-15 Automatic Concrete hollow block making machine is an affordable option for new investors looking to start a concrete block factory with minimal risk and high potential returns. It offers competitive pricing and versatility.

Get Free Quote of QT4-15 Automatic Concrete hollow block Making Machine

QT4-15 Hollow Block Machine Overview

The QT4-15 automatic hollow block machine is versatile and popular, capable of producing hollow blocks, paver bricks, and curbstones with interchangeable molds.

Production Capacity: The QT4-15 Hollow Block Machine can produce up to 7,680 pieces of 8-inch hollow blocks per 8-hour shift, making it ideal for high-demand construction projects.

Price Range: The cost ranges from $16,100 to $29,300 USD, depending on the number of hollow block molds, brick pallets, and other customizable options.

1. Specialized Brick Design:

The QT4-15 Automatic Concrete hollow block Making Machine is specifically engineered to produce hollow bricks, standard bricks, and multi-hole bricks, meeting the needs of various types of building materials.

2. Innovative Double-End Vibration Technology:

The QT4-15 Automatic Concrete hollow block Making Machine is equipped with advanced double-end synthesis output vibration technology, which optimizes vibrator placement to ensure an even distribution of exciting force on the vibrating table.

3. Adjustable Hydraulic Control:

The QT4-15 Automatic Concrete hollow block Making Machine is equipped with an advanced hydraulic tunable technology, allowing for straightforward adjustments to system pressure and flow rate. This flexibility allows for production with a variety of raw materials, including concrete, fly ash, and slag.

4. Separate Vibration Control:

The QT4-15 Automatic Concrete hollow block Making Machine utilizes state-of-the-art vibration technology and a PG anti-arching device to separate material distribution from molding vibration, ensuring optimal material placement and precise brick formation.

5. Multi-Purpose Functionality:

The QT4-15 Automatic Concrete hollow block Making Machine is a highly versatile machine, suitable for producing a wide range of blocks, including concrete blocks, fly ash bricks, slag blocks, and more. With interchangeable molds, it can produce different specifications such as wall blocks, standard bricks, hollow blocks, and perforated bricks.

Paraments Of QT4-15 Automatic Concrete hollow block machine Host Machine:

| Item | Paraments |

| Host brick machine | Shed or workshop area :100 square meters

Factory area:1200 square meters Labor quantity:4 Moulding area: 1006*600mm Vibration Frequency: 4600 times/M Machine power 29kw Vibration force 55-75 KN Moulding Period 12-20 S Diesel Generator Capacity: 50KVA Machine size: 3940×2250×2450mm Machine weight: 4500kg |

QT4-15 Automatic Concrete hollow block machine Daily Production Capacity:

| QT4-15 hollow block machine production capacity | ||||||

| Size(LxWxH) (mm) | Forming Period (S) | Photo | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 | 15 |  |

3 | 720 | 5760 |

| (2) | hollow block 400*200*200 | 15 |  |

4 | 960 | 7680 |

| (3) | hollow block 400*150*200 | 15 |  |

5 | 1200 | 9600 |

| (4) | hollow block 400*100*200 | 15 |  |

8 | 1920 | 15360 |

| (5) | Solid Brick 240*50*115 | 15 |  |

30 | 7200 | 57600 |

| (6) | Porous Brick 240*115*90 | 15 |  |

12 | 2880 | 23040 |

| (7) | Curbstone 500*200*300 | 15 |  |

2 | 480 | 3840 |

| (8) | “I” shape paver brick 200*163*60 | 20 |  |

10 | 1800 | 14400 |

| (9) | “S” Shape Paver Brick 225*112.5*60 | 20 |  |

14 | 2520 | 20160 |

| (10) | Holland Brick 200*100*60 | 20 |  |

16 | 2880 | 23040 |

| (11) | Square Paver 250*250*60 | 20 |  |

3 | 540 | 4320 |

Detailed Introduction of QT4-15 Automatic Concrete hollow block Machine Line:

| Number | Item | Function |

| 1 | PLD1200 Two Hopper Batching Machine | Measure and mix the raw materials |

| 2 | JS500 Concrete Mixer (with elevator model) |

For hollow block lines without cement silos, workers manually load cement bags into the hopper. |

| 3 | Belt Conveyor | Carry mixed material from mixer to Block machine |

| 4 | Host block making machine (Inc : PLC Panel, Hydraulic Station) | Produce different sizes of blocks by changing molds |

| 5 | Double Row Blocks Stacking Machine | Stack the finished hollow blocks to several layers |

QT4-15 Automatic Hollow Block Machine Line Basic Requirements for Production Start:

The following information for the QT4-15 hollow block machine is provided for theoretical reference only.

Actual production data may vary slightly depending on the specific raw materials used.

| Land area | 1200-2500 Square Meters | Water Consumption | 4.8 T/day |

| Workshop area | 200 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V; 50HZ/60HZ |

| Labors Quantity | 5 workers | Power Consumption | 68.4KW*8 Hours= 547.2KWH; |

| Cement Consumption | 12.6 Tons per day | Sand consumption | 50.4 tons per day |

| Crushed stones consumption | 62.4 tons per day |

Packing List for the QT4-15 Automatic Hollow Block Machine Full Production Line:

| 1 | PLD1200 concrete batching machine | 1 set |

| 2 | JS500 concrete mixer | 1 set |

| 3 | 6M Belt Conveyor | 1 set |

| 4 | Brick Pallet Feeder | 1 set |

| 5 | QT4-15 Host Brick Machine | 1 set |

| 6 | PLC control Panel | 1 set |

| 7 | Hydraulic Station | 1 set |

| 8 | Hollow block conveyor Machine | 1 set |

| 9 | JQ350 Pigment Mixer | 1 set |

| 10 | pigments feeding machine | 1 set |

| 11 | hollow blocks Stacking Machines | 1 set |

| 12 | Manual trolleys | 2 set |

| 13 | Brick Pallet Loading Machine | 1 set |

| 14 | GMT brick pallet | 1200 pieces |

| 15 | Spare parts | 1 set |

Loading: The complete QT4-15 hollow block making machine line requires two 40-foot high containers for shipping.

QT4-15 Automatic Hollow Block Machine FAQ:

1. How many workers are needed for the QT4-15Automatic Hollow Block Machinebrick machine?

A total of 8 workers are required:

– 1 worker to load raw materials into the batching machine

– 1 worker to add cement (if no cement silo is used)

– 1 worker to operate the JS500 mixer and batching machine

– 1 worker to place brick pallets on the pallet feeder

– 1 worker to operate the main brick machine

– 1 worker to drive the forklift and transport finished blocks after stacking

– 2 standby workers to handle auxiliary tasks (e.g., adding water to the water tank, watering finished blocks)

2. How much space is needed for the QT4-15 Automatic Hollow Blockmachine?

– The workshop area required for the machine is approximately 200 square meters;

– Additional space for storage and drying is around 3300 square meters. The exact area may vary depending on your specific needs.

3. What is the theoretical daily capacity of the QT4-15 Automatic Hollow Blockmachine?

– Solid Brick (240*115*53mm): 33,600 – 36,000 pieces (28 pieces per mould)

– Hollow Block (390*190*190mm): 4,800 – 6,000 pieces (4 pieces per mould)

– Porous Block (240*115*90mm): 16,800 – 19,200 pieces (14 pieces per mould)

4. What types of blocks can the QT4-15 Automatic Hollow Blockmachineproduce?

The QT4-15 Automatic Hollow Block machinecan produce:

– Paver blocks

– Solid blocks

– Hollow blocks

– Curb stones

(Note: Curb stone length should be less than 1000mm due to the moulding area of 1020*570mm)

5. What does the client need to prepare before the engineer’s arrival for installation?

Before the engineer arrives for installation, the client should prepare:

– Power supply

– Water supply

– Concrete ground foundation (with appropriate thickness)

-340 liters of 68# anti-wear hydraulic oil

Working Videos:

1. How many workers are needed for the QT4-15Automatic Hollow Block Machinebrick machine?

A total of 8 workers are required:

– 1 worker to load raw materials into the batching machine

– 1 worker to add cement (if no cement silo is used)

– 1 worker to operate the JS500 mixer and batching machine

– 1 worker to place brick pallets on the pallet feeder

– 1 worker to operate the main brick machine

– 1 worker to drive the forklift and transport finished blocks after stacking

– 2 standby workers to handle auxiliary tasks (e.g., adding water to the water tank, watering finished blocks)

2. How much space is needed for the QT4-15 Automatic Hollow Blockmachine?

– The workshop area required for the machine is approximately 200 square meters;

– Additional space for storage and drying is around 3300 square meters. The exact area may vary depending on your specific needs.

3. What is the theoretical daily capacity of the QT4-15 Automatic Hollow Blockmachine?

– Solid Brick (240*115*53mm): 33,600 – 36,000 pieces (28 pieces per mould)

– Hollow Block (390*190*190mm): 4,800 – 6,000 pieces (4 pieces per mould)

– Porous Block (240*115*90mm): 16,800 – 19,200 pieces (14 pieces per mould)

4. What types of blocks can the QT4-15 Automatic Hollow Blockmachineproduce?

The QT4-15 Automatic Hollow Block machinecan produce:

– Paver blocks

– Solid blocks

– Hollow blocks

– Curb stones

(Note: Curb stone length should be less than 1000mm due to the moulding area of 1020*570mm)

5. What does the client need to prepare before the engineer’s arrival for installation?

Before the engineer arrives for installation, the client should prepare:

– Power supply

– Water supply

– Concrete ground foundation (with appropriate thickness)

-340 liters of 68# anti-wear hydraulic oil

Related Products

Related News

The QT4-15 automatic brick making machine is a versatile and high-performance piece of equipment, ideal for producing a wide range of […]

The QT4-15 automatic brick making machine requires regular maintenance to ensure optimal performance and longevity. Key maintenance tasks include daily cleaning […]

If you’re in the construction industry or planning to invest in a reliable block-making solution, you’ve likely come across the […]

The QT4-15 automatic brick making machine offers numerous advantages for construction and manufacturing businesses. This versatile hydraulic cement block machine excels […]

The QT4-15 automatic brick making machine represents a significant advancement in construction technology, offering a perfect blend of efficiency, versatility, and […]

Installing a QT4-15 automatic brick making machine typically takes between 3 to 5 days, depending on various factors such as site […]

The QT4-15 automatic brick making machine is a sophisticated piece of equipment designed for efficient and high-quality production of concrete blocks […]

Are you looking to master the operation of the QT4-15 automatic brick making machine? This robust equipment, designed for efficiency […]