M7MI TWIN Diesel Hydraform Soil Brick Machine

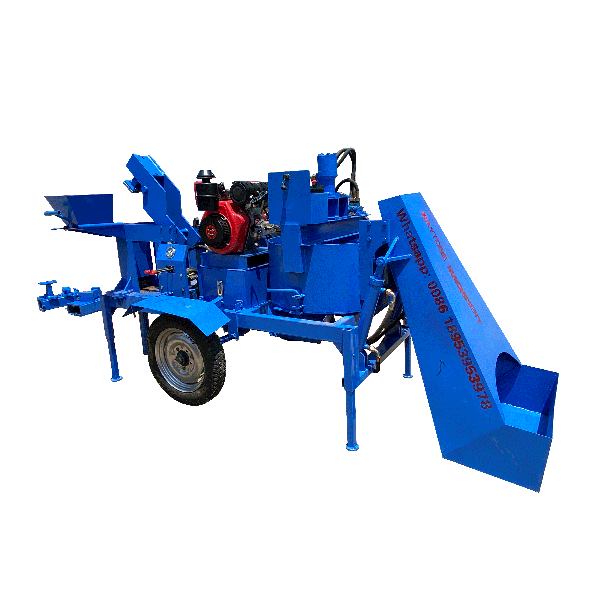

The M7MI TWIN Diesel Hydraform Soil Brick Machine is a highly efficient, movable hydraulic brick-making machine powered by a diesel engine, ideal for producing interlocking bricks using soil, clay, or earth as raw materials.

Introduction Of M7MI TWIN Diesel Hydraform Soil Brick Machine

The M7MI TWIN Diesel Hydraform Soil Brick Machine is a versatile, movable brick-making machine that operates using a diesel engine, making it ideal for locations with power shortages. It uses local soil, clay, or earth as raw materials to produce high-density interlocking bricks.

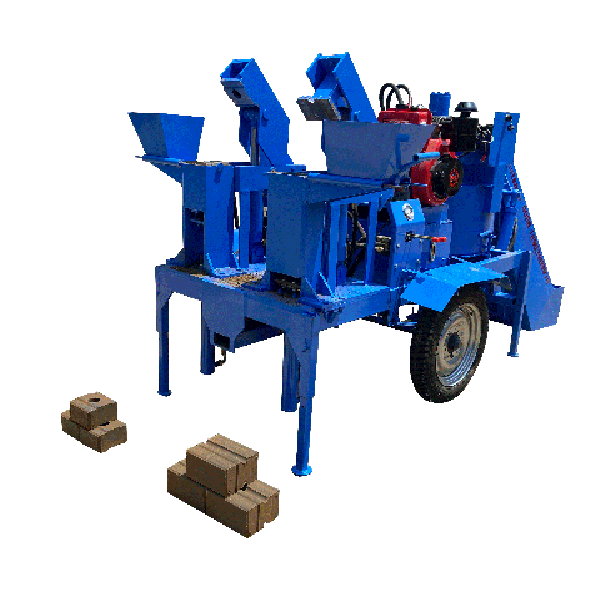

This machine is designed with two working platforms, allowing for a daily production capacity of up to 3,840 bricks. It features a hydraulic pressing system that ensures high-strength bricks with precise dimensions.

The machine comes equipped with a concrete pan mixer, hydraulic chamber, and raw material loading hopper, all mounted on a trailer chassis for easy transport.

The M7MI TWIN is suitable for producing various types of interlocking bricks, including four-direction interlocking blocks that can reduce the amount of cement and mortar required during the building process. The machine’s moulds are precisely cut using linear cutting technology and heat-treated to prolong their lifespan.

The M7MI TWIN Diesel Hydraform Soil Brick Machine provides an efficient, mobile, and environmentally-friendly solution for producing durable and high-quality bricks for construction projects, making it a popular choice for contractors and small-scale builders in areas with limited access to electricity.

Advantages of M7MI TWIN Diesel Hydraform Soil Brick Machine

1. Diesel Power: The diesel engine provides an independent power source, making the M7MI TWIN ideal for regions with power shortages or off-grid locations. It ensures continuous operation without relying on electricity, improving flexibility and mobility for various construction projects.

2. Portable and Mobile: The entire machine is mounted on a trailer chassis, allowing it to be easily towed by a car or truck to different project sites. Its mobility makes it perfect for remote areas and construction locations with limited access to heavy machinery.

3. Hydraulic Pressing System: The hydraulic system applies high pressure to the raw materials, producing bricks with superior strength and density. The hydraulic chamber ensures uniform pressing, resulting in high-quality, durable bricks with consistent dimensions and optimal compactness for construction.

4. Durable Moulds: The moulds are made using linear cutting and heat treatment technologies. The linear cutting ensures precise brick size, while heat treatment extends the lifespan of the moulds, reducing wear and tear, and ensuring high productivity over time.

Get Free Quote of M7MI TWIN Diesel Hydraform Soil Brick Machine

M7MI TWIN Diesel Hydraform Soil Brick Machine Overview

The M7MI TWIN Diesel Hydraform Soil Brick Machine is a movable hydraulic brick-making machine powered by a diesel engine. It uses earth, soil, or clay as raw materials and features two working platforms, allowing for high productivity.

Production Capacity:

- Daily Output: 3,840 pieces

- Special Functionality: This machine produces four-direction interlocking bricks, enabling the blocks to interlock from front to back and top to bottom, reducing the need for cement and mortar during construction.

- Price Range: About $5,600 USD, depending on specific configurations and mold options.

1. Efficient Production: The M7MI TWIN can produce up to 3,840 bricks per day.Its two working platforms ensure continuous operation, increasing productivity and reducing downtime, while the 15-second pressing cycle maximizes output.

2. Interlocking Brick Production: This machine is capable of producing four-direction interlocking bricks, which means the bricks can lock together from top to bottom and front to back. This interlocking feature reduces the need for cement and mortar, making the construction process faster and more cost-effective.

3. Customizable Raw Materials Formula: The M7MI TWIN offers two different raw material formulas: one with 80-90% clay, 6-8% cement, and 3% water, and another with 97% clay and 3% water. This flexibility allows for optimal brick quality based on local soil conditions, offering cost-effective solutions for different environments.

4. Hydraulic Cooling System: The hydraulic cooling system is controlled by a temperature switch that runs automatically, based on the hydraulic oil temperature. This system helps maintain the optimal performance of the hydraulic system, reducing energy consumption and extending the life of the machine, ensuring long-term reliability.

Paraments Of M7MI TWIN Diesel Hydraform Soil Brick Machine

| Item | Paraments |

| Host brick machine | Dimension of host machine:3500x1600x1600mm

Shaping method:Hydraulic press Power supply:Diesel engine 192F with electric start Material feeding type:Hopper feeding Power of host machine:18HP Weight of host machine:2T Models of mixer:JQ200 Forming period:15s Transportation:Wheel type |

M7MI TWIN Diesel Hydraform Soil Brick Machine Daily Production Capacity

| Seq. | Block Size | Block Photo | Pcs/Mould | Pcs/hour | Pcs/Day |

| 1 | 230*220*110mm |  |

1 | 200-250 | 1600-2400 |

| 2 | 230*140*110mm |  |

1 | 200-250 | 1600-2400 |

| 3 | 230*230*115mm |  |

1 | 200-250 | 1600-2400 |

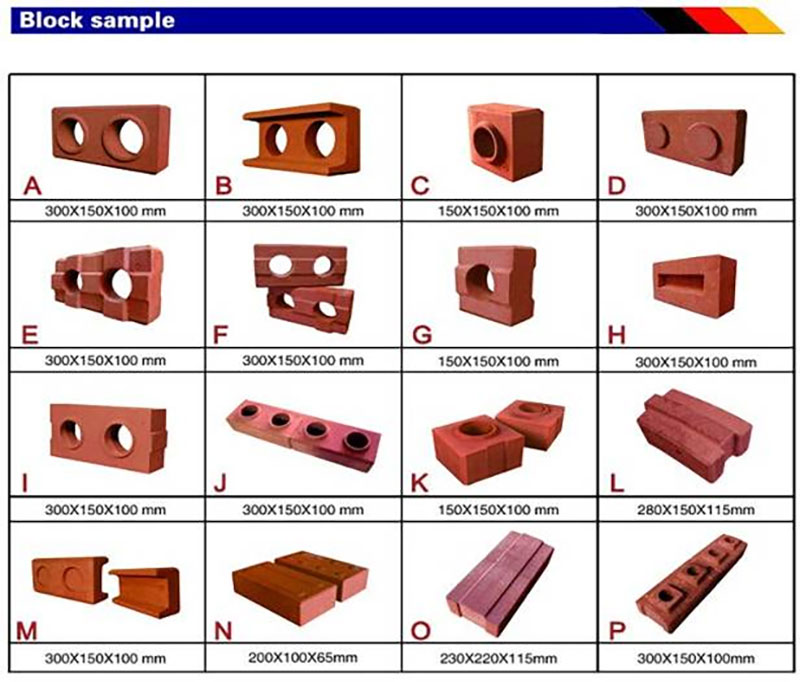

M7MI TWIN Diesel Hydraform Soil Brick Machine - Sample Brick Showcase

Clients can review the clay brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Another model of M7MI interlocking block making machine

Another model of the M7MI interlocking block-making machine is the M7MI TWIN.

The key difference between the two lies in their design: the M7MI features a single working platform, while the M7MI TWIN is equipped with dual working platforms. This distinction results in different daily production capacities, although both machines operate on the same working principle.

Additionally, the M7MI lacks a raw materials loading hopper.

Paraments Of M7MI Diesel Hydraform Soil Brick Machine

| Item | Paraments |

| Host brick machine | Dimension of host machine:2950*1400*1600mm

Shaping method:Hydraulic press Power supply:Diesel engine 192F with electric start Material feeding type:Hopper feeding Power of host machine:8HP Weight of host machine:950kg Forming period:15s Transportation:Wheel type |

1. What is the recommended clay raw materials formula for the M7MI TWIN diesel brick machine?

Two formulas are commonly used:

- 80-90% clay, 6-8% cement, and 3% water.

- 97% clay and 3% water.

2. What are the advantages of the M7MI TWIN diesel hydraform brick machine?

Powered by a diesel engine, it avoids limitations in areas with power shortages.

The machine’s concrete pan mixer, hydraulic pressing chamber, and raw material loading hopper are mounted on a trailer chassis, making it portable to any project site.

Hydraulic system ensures high-density, high-strength bricks.

Brick molds undergo precision linear cutting for accurate sizing and heat treatment to extend mold lifespan.

3. What type of hydraulic oil is recommended for this machine?

- Standard: 46# anti-wear hydraulic oil.

- Cold climates: 32# hydraulic oil.

4. What is the capacity of the pan mixer?

- Input capacity: 320L.

- Output capacity: 200L.

5. Can this machine produce unique interlocking bricks?

Yes, the M7MI TWIN produces bricks that interlock from all four directions—front, back, top, and bottom—reducing the need for cement and mortar during construction.

6. How is the diesel clay brick machine operated?

- Start the diesel engine.

- Add raw materials to the mold chamber.

- Use one lever to press the raw materials; a meter shows the applied pressure.

- After 15 seconds, pull another lever to eject the finished brick.

7. How many workers are needed to operate this machine?

A total of three workers:

- Two operators.

- One worker to supply raw materials to the pan mixer and the working platform hopper.

8. Does the M7MI TWIN machine include a hydraulic cooling system?

Yes, it features an automatic hydraulic cooling system controlled by a temperature switch, reducing energy consumption based on hydraulic oil temperature.

9. What is the quality of bricks produced by this machine?

The bricks have:

- High strength (above 12 MPa).

- Excellent compactness, frost resistance, and impermeability.

- Superior sound and heat insulation properties.

- Accurate dimensions and eco-friendly characteristics.

10. Can this machine use an electric motor?

Yes, an electric motor can be installed as an optional power source.

Working Videos

1. What is the recommended clay raw materials formula for the M7MI TWIN diesel brick machine?

Two formulas are commonly used:

- 80-90% clay, 6-8% cement, and 3% water.

- 97% clay and 3% water.

2. What are the advantages of the M7MI TWIN diesel hydraform brick machine?

Powered by a diesel engine, it avoids limitations in areas with power shortages.

The machine’s concrete pan mixer, hydraulic pressing chamber, and raw material loading hopper are mounted on a trailer chassis, making it portable to any project site.

Hydraulic system ensures high-density, high-strength bricks.

Brick molds undergo precision linear cutting for accurate sizing and heat treatment to extend mold lifespan.

3. What type of hydraulic oil is recommended for this machine?

- Standard: 46# anti-wear hydraulic oil.

- Cold climates: 32# hydraulic oil.

4. What is the capacity of the pan mixer?

- Input capacity: 320L.

- Output capacity: 200L.

5. Can this machine produce unique interlocking bricks?

Yes, the M7MI TWIN produces bricks that interlock from all four directions—front, back, top, and bottom—reducing the need for cement and mortar during construction.

6. How is the diesel clay brick machine operated?

- Start the diesel engine.

- Add raw materials to the mold chamber.

- Use one lever to press the raw materials; a meter shows the applied pressure.

- After 15 seconds, pull another lever to eject the finished brick.

7. How many workers are needed to operate this machine?

A total of three workers:

- Two operators.

- One worker to supply raw materials to the pan mixer and the working platform hopper.

8. Does the M7MI TWIN machine include a hydraulic cooling system?

Yes, it features an automatic hydraulic cooling system controlled by a temperature switch, reducing energy consumption based on hydraulic oil temperature.

9. What is the quality of bricks produced by this machine?

The bricks have:

- High strength (above 12 MPa).

- Excellent compactness, frost resistance, and impermeability.

- Superior sound and heat insulation properties.

- Accurate dimensions and eco-friendly characteristics.

10. Can this machine use an electric motor?

Yes, an electric motor can be installed as an optional power source.

Related Products

Related News

The QTS2-40 manual clay brick making machine is a versatile and cost-effective solution for various construction and development projects. Its best […]

The QTS2-40 manual clay brick making machine is indeed an environmentally friendly solution for brick production. This innovative device operates without […]

The QTM4-45 mobile block machine is a highly efficient and cost-effective solution for producing concrete blocks. This egg-laying brick machine is […]

The QTM4-45 mobile block machine, also known as an egg laying brick machine or egg-laying block pressing machine, offers a […]

The QTM4-45 mobile block machine is revolutionizing small-scale block production. This compact and versatile equipment offers numerous benefits for construction projects […]

The QTS2-40 manual clay brick making machine is a cost-effective and eco-friendly solution for small-scale brick production. This versatile machine operates […]

The QTS2-40 manual clay brick making machine is highly portable and easy to move. Weighing less than many traditional block-making machines, […]

The QTM4-45 mobile block machine is designed for small-scale block production, offering impressive output for various block sizes. For 400x250x200 mm […]