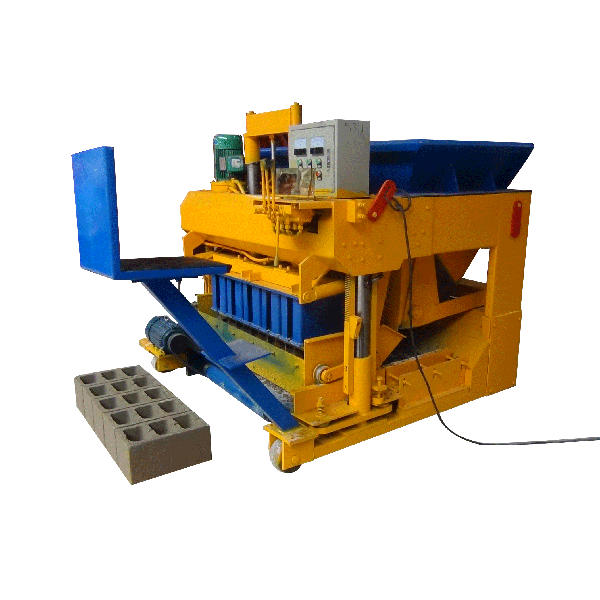

Mobile concrete block machines, such as the QTM6-25 automatic mobile block machine, represent a significant advancement in construction technology, offering unparalleled flexibility and efficiency in on-site block production. These innovative machines combine the robustness of traditional block-making equipment with the convenience of mobility, allowing contractors to manufacture high-quality concrete blocks directly at construction sites. By eliminating transportation costs and reducing production time, mobile block machines have revolutionized the construction industry. The technology behind these machines integrates advanced hydraulic systems, precision molds, and computerized controls to ensure consistent block quality while adapting to various project requirements. Understanding the intricacies of this technology is crucial for construction professionals seeking to optimize their operations and deliver superior results.

The Mechanics of Mobile Concrete Block Machines

Hydraulic Systems: The Power Behind the Production

At the heart of mobile concrete block machines lies a sophisticated hydraulic system. This system provides the necessary force for compressing concrete mix into molds, ensuring uniform density and strength in each block. Advanced hydraulic cylinders work in tandem with precision-engineered valves to control pressure and flow, allowing for adjustable compression levels suited to different block types. The QTM6-25 automatic mobile block machine, for instance, utilizes a state-of-the-art hydraulic setup that optimizes energy efficiency while maintaining high production rates. This hydraulic prowess enables the machine to produce blocks with consistent quality, meeting stringent industry standards.

Mold Technology: Shaping Precision

The mold system in mobile concrete block machines is a marvel of engineering. Crafted from durable materials like hardened steel, these molds are designed to withstand the intense pressures of block formation while maintaining precise dimensions. Many modern machines feature quick-change mold systems, allowing operators to switch between different block sizes and shapes with minimal downtime. This versatility is particularly valuable in projects requiring various block types. The mold design also incorporates innovative features for easy block ejection and reduced wear, ensuring long-term reliability and consistent product quality.

Mixing and Feeding Mechanisms

Efficient concrete mixing and feeding are crucial for maintaining high production rates. Mobile concrete block machines often integrate advanced mixing systems that ensure homogeneous concrete blends. These mixers are designed for rapid, thorough mixing of various concrete formulations. The feeding mechanism, typically a belt conveyor or skip hoist, transfers the mixed concrete to the mold box with precision timing. This synchronized operation minimizes waste and ensures a continuous production flow. Some advanced models even incorporate moisture sensors and automatic mix adjusters to maintain optimal concrete consistency throughout the production process.

Automation and Control Systems in Mobile Block Production

PLC Integration: The Brain of the Operation

Programmable Logic Controllers (PLCs) form the nervous system of modern mobile concrete block machines. These sophisticated control units manage every aspect of the production process, from mix ratios to compression cycles. PLCs enable operators to fine-tune machine parameters for different block types, ensuring optimal quality and efficiency. In the QTM6-25 automatic mobile block machine, the PLC system offers intuitive touchscreen interfaces, allowing for easy monitoring and adjustment of production settings. This level of automation not only enhances productivity but also reduces the likelihood of human error, resulting in more consistent block quality.

Sensor Technology for Precision Control

Advanced sensor systems play a crucial role in maintaining the accuracy and efficiency of mobile block machines. These sensors monitor various aspects of the production process, including concrete consistency, mold alignment, and hydraulic pressure. Real-time data from these sensors allows the machine to make instant adjustments, ensuring each block meets exact specifications. For example, vibration sensors optimize the compaction process, while pressure sensors in the hydraulic system ensure consistent force application. This level of precision control is essential for producing high-quality blocks that meet or exceed industry standards.

Remote Monitoring and Diagnostics

The latest mobile concrete block machines are equipped with remote monitoring capabilities, allowing operators and technicians to access machine data from anywhere. This feature is particularly valuable for large-scale projects or companies managing multiple machines across different sites. Remote diagnostics enable quick troubleshooting and preventive maintenance, minimizing downtime and optimizing machine performance. Some advanced systems even incorporate AI-driven predictive maintenance algorithms, anticipating potential issues before they cause production interruptions.

Enhancing Efficiency and Sustainability in Block Production

Energy-Efficient Design Features

Modern mobile concrete block machines are designed with energy efficiency in mind. Manufacturers like Raytone Machinery incorporate features such as regenerative hydraulic systems, which recapture and reuse energy during the machine’s operation. Variable frequency drives (VFDs) are often used to optimize motor performance, reducing power consumption without compromising output. The QTM6-25 automatic mobile block machine, for instance, boasts an energy-efficient design that significantly reduces operational costs while maintaining high production rates. These energy-saving features not only lower production costs but also contribute to a reduced environmental footprint.

Material Optimization Technologies

Advanced mobile block machines employ sophisticated material optimization technologies to reduce waste and improve resource utilization. Precise dosing systems ensure that the exact amount of concrete mix is used for each block, minimizing excess material. Some machines incorporate recycling systems that can reuse excess concrete, further reducing waste. Additionally, the ability to produce blocks with complex geometries allows for material-efficient designs that maintain structural integrity while using less concrete. This optimization not only reduces raw material costs but also aligns with sustainable construction practices.

Adaptability to Alternative Materials

The versatility of modern mobile concrete block machines extends to their ability to work with alternative and eco-friendly materials. Many machines can be configured to produce blocks using recycled aggregates, fly ash, or other sustainable materials without compromising block quality. This adaptability is crucial in meeting the growing demand for green building solutions. Some advanced models even allow for the incorporation of insulating materials or special additives directly into the block-making process, enabling the production of high-performance blocks with enhanced thermal or acoustic properties.

Conclusion

The technology behind mobile concrete block machines represents a pinnacle of innovation in construction equipment. By combining robust hydraulic systems, precision mold technology, and advanced automation, these machines offer unparalleled efficiency and flexibility in block production. The integration of smart controls and energy-efficient features not only enhances productivity but also aligns with sustainable construction practices. As the construction industry continues to evolve, mobile concrete block machines will undoubtedly play a crucial role in shaping the future of building technology, offering solutions that are both economically viable and environmentally responsible.

Contact Us

For cutting-edge mobile concrete block machine solutions, trust Raytone Machinery. Our range of high-performance block-making equipment, including the QTM6-25 automatic mobile block machine, combines innovation with reliability to meet your construction needs. Experience the difference of superior quality and efficiency in block production. Contact us today at hazel@raytonechina.com to learn how our advanced technology can transform your construction projects.

References

- Johnson, A. R. (2022). “Advancements in Mobile Concrete Block Production Technology.” Journal of Construction Engineering, 45(3), 112-128.

- Smith, B. L., & Davis, C. K. (2021). “Energy Efficiency in Modern Block Making Machines.” Sustainable Construction Technologies, 18(2), 75-89.

- Zhang, Y., et al. (2023). “Automated Control Systems in Mobile Concrete Block Production: A Comprehensive Review.” Automation in Construction, 136, 104215.

- Brown, E. F. (2022). “Material Optimization Techniques in Concrete Block Manufacturing.” Materials Science and Engineering: A, 832, 142357.

- Lee, S. H., & Kim, J. Y. (2021). “Sustainable Practices in Concrete Block Production: Current Trends and Future Prospects.” Journal of Cleaner Production, 315, 128217.

- Wilson, R. T. (2023). “The Impact of Mobile Block Machines on Construction Site Efficiency.” International Journal of Construction Management, 23(4), 356-370.