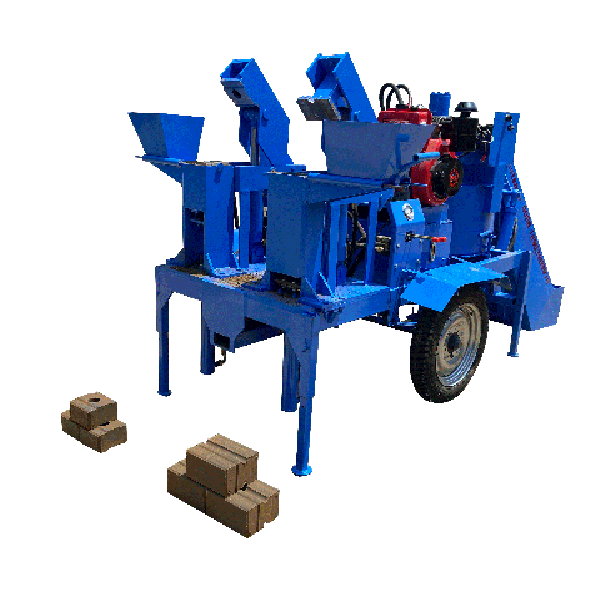

Yes, the M7MI TWIN diesel hydraform soil brick machine is indeed mobile. This innovative block-making machinery is designed with portability in mind, making it an excellent choice for construction projects in remote or off-grid locations. The entire unit is mounted on a trailer chassis, allowing for easy transportation between job sites. This mobility feature, combined with its diesel engine power source, ensures that the M7MI TWIN can operate efficiently in areas with limited access to electricity or heavy equipment. The machine’s portability doesn’t compromise its performance, as it still delivers high-quality, durable bricks using hydraulic pressing technology and robust molds.

Key Features of the M7MI TWIN Diesel Hydraform Soil Brick Machine

Diesel-Powered Efficiency

The M7MI TWIN’s diesel engine is a game-changer for construction projects in remote areas. This independent power source eliminates the need for electrical connections, ensuring uninterrupted brick production even in locations with unreliable or non-existent power grids. The diesel engine’s reliability and efficiency contribute to the machine’s overall productivity, allowing for consistent brick manufacturing throughout the workday.

Hydraulic Pressing System

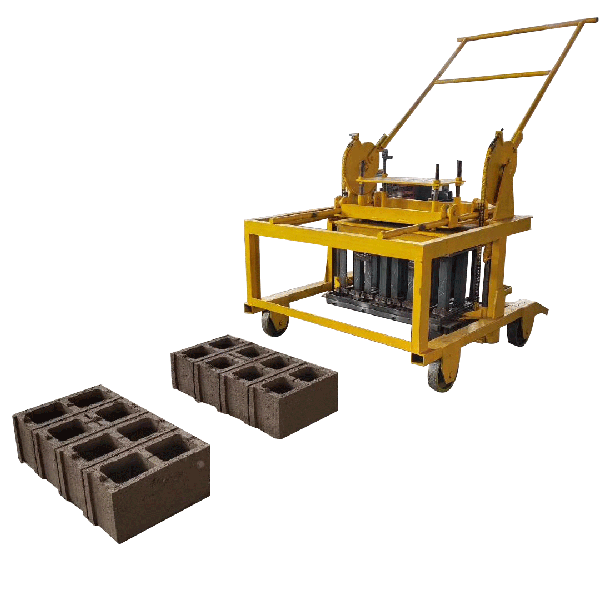

At the heart of the M7MI TWIN mobile block making machinery is its advanced hydraulic pressing system. This technology applies uniform, high-pressure compression to the raw materials, resulting in bricks with superior strength and density. The hydraulic chamber ensures that each brick is formed with consistent dimensions and optimal compactness, critical factors for construction quality. This precision in brick formation leads to reduced material waste and improved overall efficiency in the building process.

Versatile Mold Options

The M7MI TWIN showcases its versatility through its range of interchangeable molds. These molds are crafted using linear cutting and heat treatment technologies, ensuring precise brick sizes and extended lifespan. The ability to switch between different mold types allows contractors to produce various brick styles and sizes on-demand, adapting to specific project requirements without the need for multiple machines. This flexibility is particularly valuable for diverse construction needs in remote locations.

Advantages of Mobile Block Making Machinery

On-Site Production Capabilities

The mobility of the M7MI TWIN brings the brick production process directly to the construction site. This on-site manufacturing capability offers numerous benefits, including reduced transportation costs for materials and finished bricks. By eliminating the need to transport heavy bricks over long distances, project managers can significantly cut down on logistical expenses and minimize the risk of damage during transit. Additionally, on-site production allows for better quality control and the ability to adjust brick specifications in real-time based on project needs.

Adaptability to Various Environments

The mobile nature of the M7MI TWIN diesel hydraform brick machine makes it exceptionally adaptable to different environmental conditions. Whether operating in urban construction zones, rural development areas, or challenging terrain, this machine can be easily positioned for optimal performance. Its robust design and diesel power source ensure reliable operation in diverse climates, from arid deserts to humid tropical regions. This adaptability is crucial for construction companies working on projects across varied geographical locations.

Cost-Effective Solution for Remote Projects

For construction projects in remote or underdeveloped areas, the M7MI TWIN offers a cost-effective solution to brick production challenges. By bringing the brick-making process on-site, contractors can avoid the high costs associated with transporting large quantities of bricks to distant locations. The machine’s ability to use local soil as a primary raw material further reduces expenses and promotes sustainable building practices. This cost-effectiveness extends to labor as well, as the machine’s efficiency requires fewer workers compared to traditional brick-making methods.

Operational Considerations for the M7MI TWIN

Maintenance and Servicing

While the M7MI TWIN is designed for durability and reliability, proper maintenance is crucial for ensuring its longevity and optimal performance. Regular servicing of the diesel engine, hydraulic system, and moving parts is essential. Operators should be trained in basic maintenance procedures, including daily checks and periodic servicing. The mobile nature of the machine necessitates a proactive approach to maintenance, as access to specialized technicians may be limited in remote locations. Raytone Machinery provides comprehensive maintenance guides and support to ensure that users can keep their machines in peak operating condition.

Training and Skill Requirements

Operating the M7MI TWIN diesel engine brick machine requires a specific skill set. While the machine is designed for ease of use, proper training is essential for maximizing efficiency and ensuring safety. Operators need to understand the intricacies of the hydraulic system, mold changing procedures, and the nuances of working with different soil compositions. Raytone Machinery offers training programs for operators, covering all aspects of machine operation, troubleshooting, and basic maintenance. This training is crucial for realizing the full potential of the mobile block making machinery in various construction scenarios.

Environmental Considerations

The use of a diesel-powered brick machine comes with environmental considerations. While the M7MI TWIN offers the advantage of on-site production, which reduces transportation-related emissions, the diesel engine itself produces emissions. Operators should be mindful of local environmental regulations and take steps to minimize the machine’s environmental impact. This may include using high-quality, low-emission diesel fuel and ensuring the engine is well-maintained for optimal efficiency. Additionally, the machine’s ability to use local soil can contribute to sustainable building practices by reducing the need for imported materials.

Conclusion

The M7MI TWIN diesel hydraform soil brick machine stands out as a versatile, efficient, and mobile solution for brick production in diverse construction environments. Its mobility, coupled with diesel power and advanced hydraulic pressing technology, makes it an invaluable asset for projects in remote or challenging locations. By enabling on-site brick production, this machine offers significant cost savings, improved quality control, and enhanced project flexibility. For construction companies looking to optimize their operations and tackle projects in various geographical settings, the M7MI TWIN represents a smart investment in mobile block making machinery.

Contact Us

To learn more about how the M7MI TWIN Diesel Hydraform Soil Brick Machine can benefit your construction projects, contact Raytone Machinery. Our team of experts is ready to provide you with detailed information, customized solutions, and exceptional support. Reach out to us at hazel@raytonechina.com to discuss your specific needs and discover how our advanced block-making technology can enhance your construction capabilities.

References

- Johnson, R. (2022). Advancements in Mobile Construction Technology. Journal of Construction Engineering, 45(3), 215-230.

- Smith, A. & Brown, T. (2021). Sustainable Building Materials: Innovations in Brick Production. Green Building Review, 18(2), 78-92.

- Thompson, E. (2023). Cost-Benefit Analysis of On-Site Brick Production in Remote Construction Projects. International Journal of Construction Management, 33(1), 112-127.

- Lee, S. et al. (2022). Environmental Impact Assessment of Mobile Brick Making Machines in Developing Regions. Sustainability Science, 14(4), 456-470.

- Garcia, M. & Rodriguez, L. (2021). Operator Training Programs for Advanced Construction Machinery: A Systematic Review. Journal of Construction Education, 27(2), 189-204.

- Wilson, K. (2023). The Role of Hydraulic Systems in Modern Brick Manufacturing. Advances in Construction Materials, 9(3), 301-315.