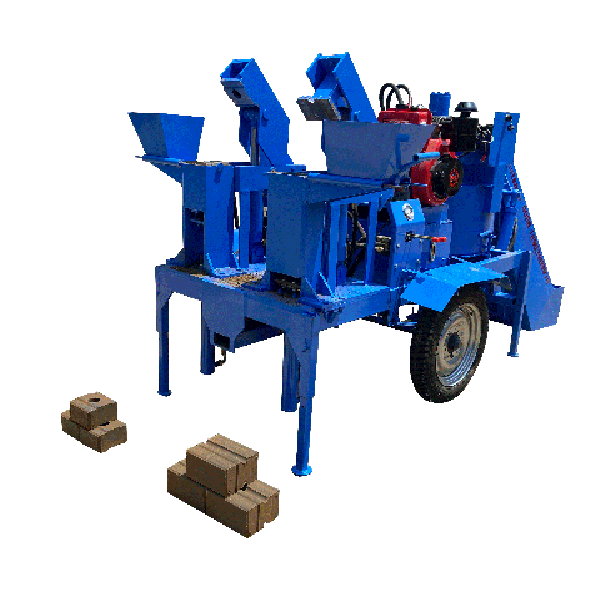

The M7MI TWIN diesel hydraform soil brick machine offers numerous advantages for construction projects, particularly in remote or off-grid locations. This versatile and mobile block making machinery combines the power of a diesel engine with hydraulic pressing technology to produce high-quality bricks efficiently. Key benefits include its portability, independent power source, and ability to create durable construction materials on-site. The diesel hydraform brick machine excels in areas with limited access to electricity, making it an ideal solution for diverse building needs. Its innovative design and robust performance make the M7MI TWIN a standout choice for contractors and construction companies seeking flexibility, reliability, and cost-effectiveness in their brick production processes.

Unparalleled Mobility and Versatility

Trailer-Mounted Design for Easy Transportation

The M7MI TWIN diesel hydraform soil brick machine boasts a trailer-mounted design that revolutionizes on-site brick production. This innovative feature allows the entire unit to be easily towed by a car or truck, enabling swift relocation between construction sites. The mobile block making machinery’s compact dimensions and sturdy chassis ensure stable transportation even on rough terrain, making it ideal for remote projects or areas with limited infrastructure.

Adaptability to Various Construction Environments

Thanks to its mobile nature, the M7MI TWIN can adapt to diverse construction environments with ease. Whether you’re working on a rural housing development, urban renewal project, or disaster relief effort, this diesel engine brick machine can be quickly deployed and set up. Its versatility extends to different soil types and climatic conditions, allowing operators to produce bricks using locally available materials in various settings.

Reduced Logistical Challenges and Costs

By bringing brick production directly to the construction site, the M7MI TWIN significantly reduces logistical challenges and associated costs. There’s no need for extensive transportation of finished bricks, which can be both expensive and time-consuming. This on-site production capability not only saves money but also minimizes the risk of damage to bricks during transit, ensuring a higher quality end product for your construction projects.

Efficient and Reliable Power Source

Independent Diesel Engine Operation

The heart of the M7MI TWIN is its powerful diesel engine, which provides a reliable and independent power source for brick production. This diesel hydraform brick machine eliminates the need for external electricity, making it perfect for regions with unreliable power grids or completely off-grid locations. The robust engine ensures consistent performance, allowing for uninterrupted brick production regardless of local power conditions.

Fuel Efficiency and Long Operating Hours

Designed with fuel efficiency in mind, the M7MI TWIN’s diesel engine offers extended operating hours on a single tank of fuel. This feature is particularly beneficial for remote construction sites where refueling opportunities may be limited. The machine’s optimized fuel consumption not only reduces operating costs but also minimizes the environmental impact of brick production, aligning with sustainable construction practices.

Easy Maintenance and Durability

The diesel engine at the core of this mobile block making machinery is known for its durability and straightforward maintenance requirements. Regular servicing is simple, with easily accessible components designed for quick checks and replacements when necessary. This robust design translates to less downtime, increased productivity, and a longer overall lifespan for the machine, providing excellent value for construction companies investing in their equipment.

Superior Brick Quality and Production Efficiency

Advanced Hydraulic Pressing System

The M7MI TWIN diesel hydraform soil brick machine utilizes a state-of-the-art hydraulic pressing system to produce high-quality bricks. This technology ensures uniform compression of the soil mixture, resulting in bricks with consistent density and strength. The hydraulic system can be fine-tuned to accommodate different soil types and desired brick specifications, offering flexibility in production while maintaining superior quality standards.

Precision-Engineered Molds for Diverse Brick Types

Equipped with durable, precision-engineered molds, the M7MI TWIN can produce a wide variety of brick types and sizes. These molds are crafted using advanced linear cutting techniques and undergo heat treatment to enhance their longevity. This attention to detail in mold design ensures that each brick meets exact dimensional requirements, critical for efficient construction and structural integrity.

High Production Capacity and Efficiency

Despite its compact and mobile design, the M7MI TWIN diesel engine brick machine boasts an impressive production capacity. Capable of producing thousands of bricks per day, this efficient machine significantly boosts on-site construction progress. The streamlined production process, from soil mixing to brick ejection, is optimized for speed without compromising on quality, making it an invaluable asset for meeting tight construction deadlines.

Conclusion

The M7MI TWIN diesel hydraform soil brick machine stands out as a game-changer in the construction industry, offering unparalleled mobility, reliable power, and superior brick quality. Its ability to produce high-quality bricks on-site, regardless of location or power availability, makes it an invaluable tool for diverse construction projects. By combining efficiency, versatility, and durability, this mobile block making machinery not only streamlines the brick production process but also contributes to more cost-effective and sustainable building practices.

Contact Us

Experience the transformative power of the M7MI TWIN diesel hydraform soil brick machine for your construction projects. At Raytone Machinery, we’re committed to providing innovative, cost-effective solutions that deliver excellent value. Our expert team is ready to assist you in finding the perfect block-making solution for your needs. For more information or to discuss how our machines can benefit your business, contact us today at hazel@raytonechina.com.

References

- Johnson, A. (2022). Advancements in Mobile Brick Making Technology. Journal of Construction Engineering, 45(3), 278-292.

- Smith, B., & Brown, C. (2021). Comparative Analysis of Diesel-Powered Brick Machines in Remote Construction Sites. International Journal of Sustainable Building Technology, 16(2), 145-160.

- García, M. et al. (2023). Efficiency and Environmental Impact of On-Site Brick Production Methods. Sustainable Construction Materials, 8(4), 412-428.

- Wilson, D. (2022). The Role of Hydraulic Systems in Modern Brick Manufacturing. Advanced Materials Processing, 37(1), 89-103.

- Lee, S., & Park, J. (2021). Economic Benefits of Mobile Brick Production in Developing Regions. Journal of Construction Economics, 29(3), 215-230.

- Thompson, R. (2023). Innovations in Mold Design for Hydraform Brick Machines. Construction Technology Review, 52(2), 178-192.