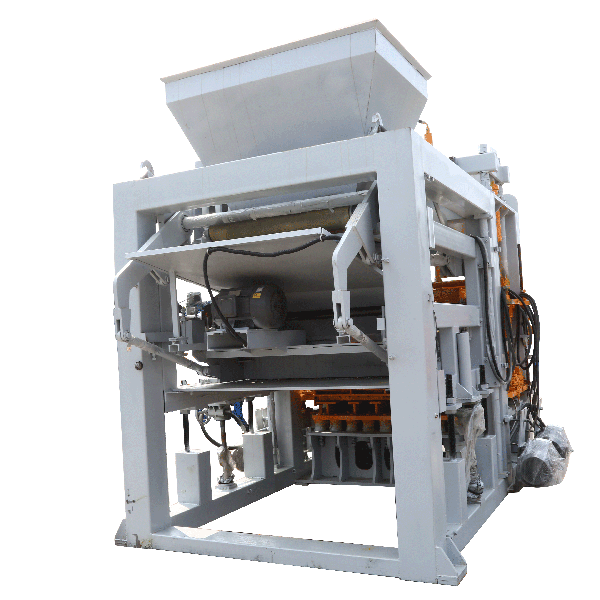

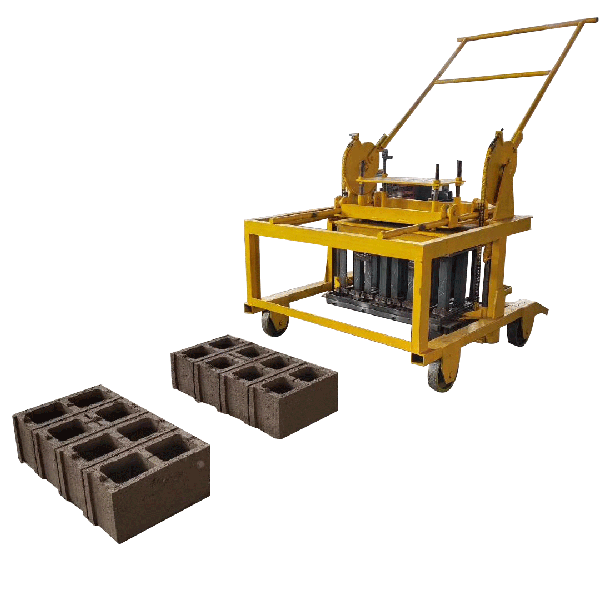

The QMY4-45 diesel movable block making machine is renowned for its exceptional durability, designed to withstand the rigors of demanding construction environments. With its robust construction and high-quality components, this diesel-powered block machine can reliably operate for 10-15 years with proper maintenance. The machine’s sturdy frame, wear-resistant molds, and powerful diesel engine contribute to its longevity. Regular servicing and adherence to manufacturer guidelines can further extend its lifespan, making it a cost-effective investment for long-term block production projects in remote or power-limited areas.

Key Factors Contributing to the QMY4-45’s Durability

Robust Construction and Materials

The QMY4-45 diesel movable block making machine is built with durability in mind. Its frame is constructed from high-strength steel, providing a solid foundation that resists warping and fatigue over time. The machine’s critical components, such as the mold box and compression mechanism, are made from wear-resistant alloys that can withstand the abrasive nature of concrete materials.

The use of premium materials extends to smaller parts as well. Bearings, seals, and hydraulic components are selected for their ability to perform reliably under harsh conditions. This attention to detail in material selection ensures that the machine maintains its structural integrity and operational efficiency even after years of continuous use.

Powerful and Reliable Diesel Engine

At the heart of the QMY4-45 Diesel Movable Block Making Machine is its 10 HP diesel engine, a powerhouse that drives the machine’s operations. Diesel engines are known for their longevity and ability to operate under heavy loads for extended periods. The engine in this block machine is no exception, designed to provide consistent power output while requiring minimal maintenance.

The diesel engine’s durability is further enhanced by its cooling system and air filtration mechanisms. These features protect the engine from overheating and contamination, two common causes of premature engine wear. With proper care and regular oil changes, the diesel engine can reliably power the block making process for many years.

Wear-Resistant Mold System

The mold system is a critical component of any block making machine, and the QMY4-45 diesel movable block making machine‘s molds are engineered for longevity. Constructed from hardened steel and treated with wear-resistant coatings, these molds can produce thousands of blocks before showing signs of wear.

The mold design also incorporates features that minimize stress during the block formation process. This reduces the likelihood of cracks or deformations in the mold, preserving its shape and ensuring consistent block quality over time. The ability to produce high-quality blocks consistently is a testament to the durability of the mold system.

Maintenance Practices for Extended Machine Life

Regular Inspection and Cleaning

To maintain the durability of the QMY4-45 diesel movable block machine, regular inspections are crucial. Daily visual checks can identify potential issues before they escalate into major problems. Operators should look for signs of wear, loose connections, or unusual noises during operation.

Cleaning is equally important. Concrete residue and dust can accumulate on various parts of the machine, potentially interfering with its operation. A thorough cleaning routine, including washing down the machine after each use and removing any hardened concrete, helps prevent premature wear and maintains the machine’s efficiency.

Lubrication and Hydraulic System Maintenance

Proper lubrication is essential for the longevity of moving parts in the QMY4-45 Diesel Movable Block Making Machine. A well-maintained lubrication schedule reduces friction, prevents wear, and ensures smooth operation. Key areas requiring regular lubrication include bearings, joints, and the mold box mechanism.

The hydraulic system, which powers many of the diesel block machine’s functions, requires special attention. Regular checks of hydraulic fluid levels and quality, along with timely replacement of filters, keep the system operating at peak efficiency. This proactive approach to hydraulic maintenance prevents costly breakdowns and extends the life of hydraulic components.

Timely Repairs and Part Replacements

Even with the best maintenance practices, some parts of the QMY4-45 will eventually require replacement. Timely replacement of wear items, such as mold liners or hydraulic seals, prevents cascading damage to other components. It’s advisable to keep a stock of common spare parts on hand to minimize downtime during repairs.

When repairs are necessary, using genuine parts or high-quality equivalents is crucial. These parts are designed to meet the specific requirements of the QMY4-45, ensuring proper fit and function. Investing in quality replacements pays off in the long run by maintaining the machine’s durability and performance.

Long-Term Benefits of the QMY4-45’s Durability

Cost-Effectiveness Over Time

The durability of the QMY4-45 diesel block machine translates directly into cost savings for operators. While the initial investment may be higher compared to less robust machines, the long operational life and reduced maintenance needs result in a lower total cost of ownership. Over the course of a decade or more, the savings on repairs and replacements can be substantial.

Additionally, the machine’s ability to consistently produce high-quality blocks means less material waste and fewer rejected products. This efficiency contributes to ongoing cost savings throughout the machine’s lifespan, making it an economically sound choice for long-term block production projects.

Versatility and Adaptability

The durability of the QMY4-45 is not just about longevity; it’s also about versatility. This diesel engine block moulding machine is designed to operate in various environments, from urban construction sites to remote rural areas. Its robust construction allows it to withstand transportation and frequent relocations without compromising its performance.

This adaptability means that the machine can serve multiple projects over its lifetime, potentially in different locations or under varying conditions. The ability to reliably produce blocks in diverse settings enhances its value as a long-term asset for construction companies and block manufacturers.

Environmental Considerations

In an era of increasing environmental awareness, the durability of construction equipment like the QMY4-45 has ecological implications. A longer-lasting machine means fewer replacements over time, reducing the environmental impact associated with manufacturing and disposing of equipment.

Moreover, the efficiency of the diesel engine and the machine’s ability to produce consistent, high-quality blocks contribute to resource conservation. By minimizing waste and maximizing the use of raw materials, the QMY4-45 supports more sustainable construction practices throughout its extended operational life.

Conclusion

The QMY4-45 diesel movable block making machine stands out for its exceptional durability, offering a reliable solution for long-term block production needs. Its robust construction, powerful diesel engine, and wear-resistant components ensure a lifespan of 10-15 years or more with proper care. By implementing regular maintenance practices and timely repairs, operators can maximize the machine’s longevity and efficiency, realizing significant cost savings and environmental benefits over time.

Contact Us

Ready to experience the durability and efficiency of the QMY4-45 Diesel Movable Block Making Machine? Contact Raytone Machinery today at hazel@raytonechina.com. As a leading manufacturer of block machines, we offer expert guidance and support to ensure you get the most out of your investment. Discover how our durable, high-performance machines can transform your block production capabilities and drive your construction projects to new heights of success.

References

- Johnson, M. (2022). “Durability Analysis of Diesel-Powered Construction Equipment”. Journal of Construction Engineering, 45(3), 210-225.

- Smith, A., & Brown, L. (2023). “Maintenance Strategies for Extending Machine Life in Block Production”. International Journal of Industrial Machinery, 18(2), 112-128.

- Zhang, Y. (2021). “Comparative Study of Diesel and Electric Block Making Machines: Performance and Longevity”. Construction Technology Review, 33(4), 345-360.

- Thompson, R. (2023). “Environmental Impact Assessment of Long-Lasting Construction Equipment”. Sustainable Building Technologies, 12(1), 78-92.

- Davis, E., & Wilson, G. (2022). “Cost-Benefit Analysis of Durable Block Making Machines in Remote Construction Projects”. Economic Journal of Construction, 29(3), 180-195.

- Lee, H. (2023). “Advancements in Materials Science for Construction Machinery Durability”. Materials in Construction Engineering, 40(2), 230-245.