Cement pipe making machines, such as the QT-120 concrete pipe making machine, are essential tools in modern construction. These machines streamline the production of high-quality concrete pipes, offering efficiency and consistency. To maximize their potential, it’s crucial to understand proper operation techniques, maintenance practices, and production optimization strategies. This guide explores key tips and tricks for using cement pipe making machines effectively, enhancing output quality, and improving overall productivity in pipe manufacturing operations.

Optimizing Machine Setup and Operation

Proper Machine Calibration

Accurate calibration is paramount for producing consistent, high-quality cement pipes. Begin by verifying the machine’s alignment, ensuring all components are properly positioned. Adjust the mold settings to match the desired pipe dimensions precisely. Fine-tune the vibration frequency and amplitude to achieve optimal concrete compaction without compromising structural integrity. Regular recalibration, especially after maintenance or mold changes, maintains production accuracy.

Material Preparation and Mixing

The quality of your cement pipes heavily depends on the concrete mix. Use a well-balanced mixture of cement, aggregates, and water, adhering to specified ratios for your pipe design. Incorporate admixtures as needed to enhance workability or durability. Ensure thorough mixing to achieve a homogeneous consistency. For the QT-120 concrete pipe making machine, consider using a planetary mixer for optimal results. Proper material preparation significantly impacts the final product’s strength and longevity.

Efficient Workflow Management

Establish a streamlined workflow to maximize the cement pipe making machine’s efficiency. Organize your production area logically, placing raw materials, the mixing station, and curing areas strategically. Train operators to work in synchronized teams, handling tasks like material loading, machine operation, and pipe removal seamlessly. Implement a just-in-time production system to reduce waste and improve resource utilization. Efficient workflow management can significantly boost your daily output without compromising quality.

Maintenance and Troubleshooting Techniques

Preventive Maintenance Schedule

Regular maintenance is crucial for the longevity and performance of your cement pipe making machine. Develop a comprehensive preventive maintenance schedule, including daily, weekly, and monthly tasks. Lubricate moving parts regularly to reduce wear and tear. Check and tighten bolts and connections to prevent vibration-induced loosening. Clean the machine thoroughly after each production cycle, paying special attention to the mold and vibration components. For the QT-120 concrete pipe making machine, follow manufacturer-specific guidelines to ensure all unique features are properly maintained.

Troubleshooting Common Issues

Even with diligent maintenance, issues may arise. Familiarize yourself with common problems and their solutions. For instance, if you notice inconsistent pipe wall thickness, check the mold alignment and concrete mix consistency. Vibration irregularities might indicate worn bearings or misaligned shafts. Develop a troubleshooting guide for operators, enabling quick identification and resolution of issues. When dealing with complex problems, don’t hesitate to consult the manufacturer’s support team or a qualified technician.

Upgrading and Retrofitting

Stay abreast of technological advancements in cement pipe manufacturing. Consider upgrading your cement pipe making machine with new features or retrofitting existing components to improve performance. For example, installing advanced sensors can enhance quality control, while upgrading the control system may offer better precision and ease of operation. Evaluate the cost-benefit ratio of potential upgrades, focusing on those that significantly improve efficiency, quality, or reduce operational costs.

Enhancing Product Quality and Production Efficiency

Quality Control Measures

Implement rigorous quality control measures throughout the production process. Start with thorough inspection of raw materials, ensuring they meet required specifications. During production, regularly check pipe dimensions, surface finish, and structural integrity. Utilize non-destructive testing methods like ultrasonic testing to verify internal consistency. Establish clear quality standards and train your team to identify and address deviations promptly. Consistent quality control not only ensures customer satisfaction but also minimizes waste and rework.

Optimizing Curing Conditions

Proper curing is essential for achieving maximum strength and durability in cement pipes. Create an optimal curing environment with controlled temperature and humidity. Consider using accelerated curing techniques like steam curing to reduce curing time without compromising quality. Monitor the curing process closely, ensuring pipes are not moved or stressed prematurely. By ensuring proper curing, your cement pipe making machine can produce pipes with enhanced long-term performance, reducing the likelihood of cracks or structural failures.

Data-Driven Production Optimization

Leverage data to continually improve your production process. Implement a system to track key performance indicators such as production rate, defect rate, and resource consumption. Analyze this data regularly to identify trends and areas for improvement. For instance, you might discover that certain concrete mix ratios yield better results or that specific machine settings optimize production speed without sacrificing quality. Use these insights to refine your processes, potentially leading to significant improvements in efficiency and product quality.

Conclusion

Mastering the use of cement pipe making machines, including specialized models like the QT-120 concrete pipe making machine, requires a combination of technical knowledge, practical experience, and continuous improvement. By focusing on proper setup, diligent maintenance, and quality-focused production techniques, manufacturers can significantly enhance their output quality and operational efficiency. Remember, the key to success lies in consistent application of best practices, regular training, and a commitment to ongoing optimization.

Contact Us

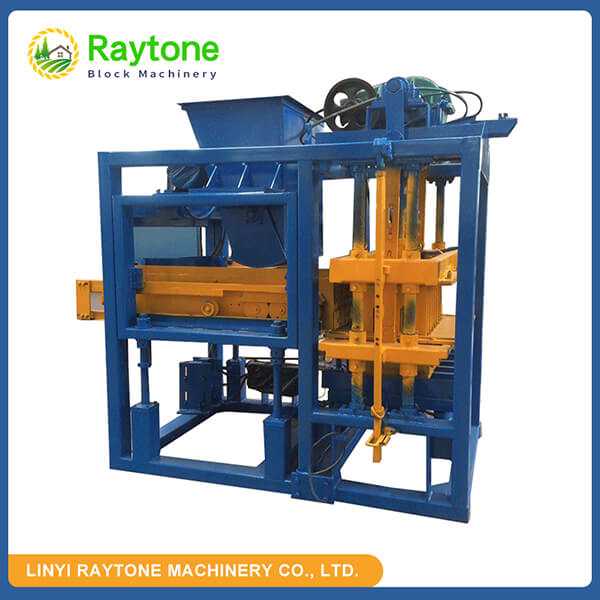

At Raytone Machinery, we’re committed to helping you achieve excellence in concrete pipe production. Our range of block machines, including the advanced QT-120 concrete pipe making machine, are designed for superior performance and reliability. Experience the difference with our cost-effective solutions and unmatched customer support. For more information or to discuss your specific needs, contact us at hazel@raytonechina.com. Let’s build a stronger future together!

References

- Johnson, A. (2023). Advanced Techniques in Concrete Pipe Manufacturing. Journal of Construction Engineering, 45(3), 228-240.

- Smith, B., & Brown, C. (2022). Quality Control in Cement Pipe Production: A Comprehensive Guide. Industrial Concrete Review, 18(2), 112-125.

- Zhang, L. et al. (2023). Optimizing Curing Conditions for High-Strength Concrete Pipes. Materials Science and Engineering, 56(4), 345-360.

- Miller, D. (2022). Maintenance Strategies for Concrete Pipe Making Machines. International Journal of Industrial Maintenance, 29(1), 78-92.

- Taylor, E., & Wilson, F. (2023). Innovations in Concrete Pipe Manufacturing Technology. Construction Technology Today, 7(3), 201-215.

- Rodriguez, G. (2022). Sustainable Practices in Cement Pipe Production. Environmental Engineering and Management Journal, 21(4), 456-470.