In the block machine industry, the choice of pallets is a critical decision that directly impacts productivity, product quality, and operational costs. Among the various options available, GMT (Glass Fiber Mat Reinforced Thermoplastics) brick pallets have emerged as a game-changer. This article delves into the features, benefits, and applications of GMT brick pallets, highlighting why they are the preferred choice for block machine manufacturers worldwide.

GMT Brick Pallet: A Success Story with Iran

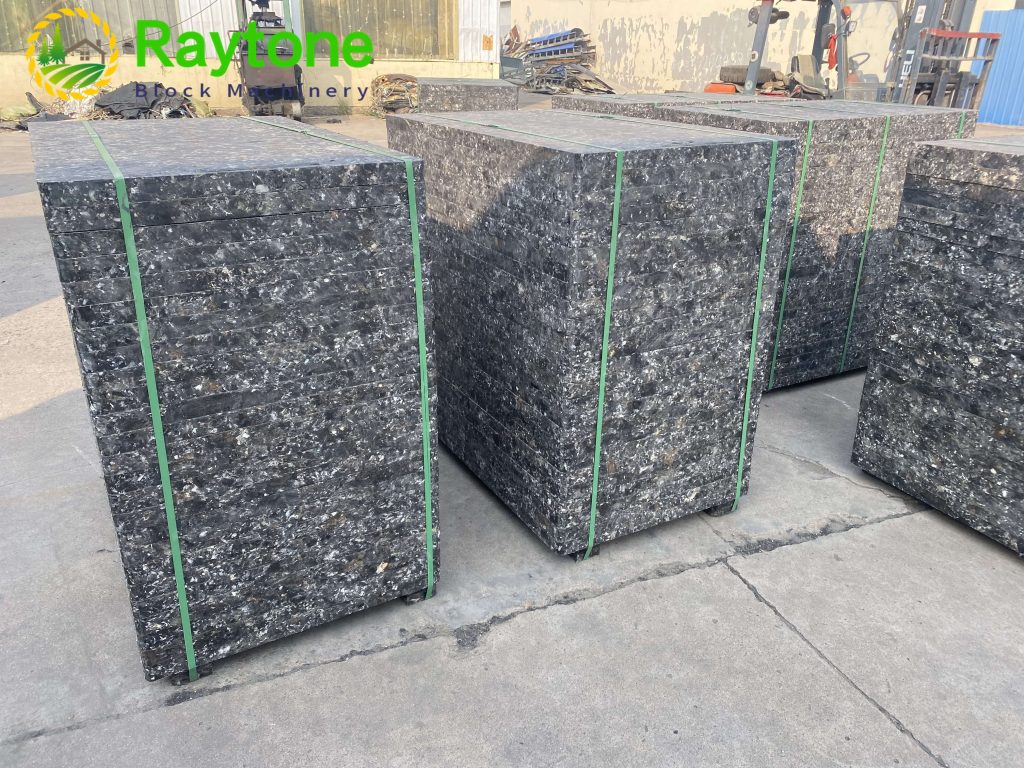

In May 2023, Ms. Emmami, a client from Iran, approached Raytone Company seeking a reliable brick pallet solution for her block machine operations. After understanding her requirements, including the brick weight per pallet, Raytone provided a competitive quote and promptly shipped 10 samples of 124075045mm GMT brick pallets.

Upon testing the samples on their block machines, Ms. Emmami was impressed with the pallets’ performance. The durability, dimensional accuracy, and ease of handling exceeded her expectations. Consequently, she placed an order for a full container, which was successfully shipped in October 2023. This case study underscores the growing demand for GMT brick pallets in the global block machine industry.

What Are GMT Brick Pallets?

GMT brick pallets are engineered using a combination of glass fiber and thermoplastic resins. This unique composition results in a pallet that is not only strong and durable but also resistant to environmental factors like moisture and temperature fluctuations. These pallets are specifically designed to meet the rigorous demands of block machine operations, making them a superior alternative to traditional wooden or plastic pallets.

Key Characteristics of GMT Brick Pallets

1. Exceptional Durability

GMT brick pallets are built to last. Their robust construction allows them to withstand heavy loads, impacts, and rough handling, ensuring a longer lifespan compared to conventional pallets.

2. Dimensional Stability

One of the standout features of GMT brick pallets is their ability to maintain precise dimensions over time. This ensures consistent alignment during block production, reducing material wastage and enhancing product quality.

3. Moisture Resistance

Unlike wooden pallets, GMT brick pallets are impervious to moisture. This prevents issues like warping, rotting, and mold growth, making them suitable for both indoor and outdoor use.

4. Lightweight Yet Strong

Despite their strength, GMT brick pallets are lightweight, making them easy to handle and transport. This feature significantly reduces labor costs and improves operational efficiency.

Applications of GMT Brick Pallets

GMT brick pallets are versatile and widely used in the production of various building materials, including:

- Concrete blocks

- Pavers

- Tiles

- Other construction products

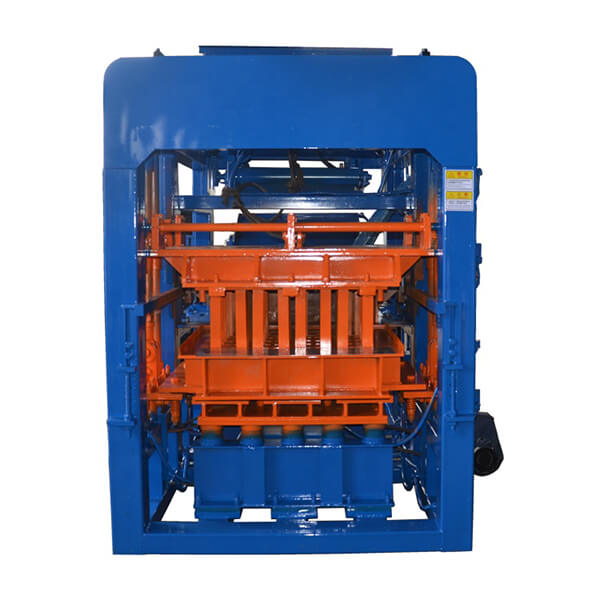

They are compatible with all types of block machines, including hydraulic, semi-automatic, and fully automatic systems. This versatility makes them an ideal choice for manufacturers looking to streamline their operations.

Advantages of GMT Brick Pallets

1. Increased Productivity

The superior strength and dimensional stability of GMT brick pallets enable faster production cycles, minimizing downtime and maximizing output.

2. Cost Savings

While the initial investment in GMT brick pallets may be higher than traditional options, their durability and low maintenance requirements result in significant long-term cost savings.

3. Improved Product Quality

The precise dimensions of GMT brick pallets ensure consistent product quality, with minimal variations in size and surface finish. This is crucial for maintaining high standards in block production.

4. Environmental Sustainability

GMT brick pallets are made from recycled materials and are fully recyclable at the end of their lifespan. This makes them an eco-friendly choice for manufacturers committed to sustainability.

5. Easy Maintenance

These pallets require minimal upkeep and can be easily cleaned, further reducing operational costs and effort.

Why Choose GMT Brick Pallets?

The block machine industry is highly competitive, and manufacturers are constantly seeking ways to optimize their operations. GMT brick pallets offer a perfect blend of durability, efficiency, and sustainability, making them the ideal solution for modern block production.

By investing in GMT brick pallets, manufacturers can:

- Enhance productivity and reduce downtime

- Achieve consistent product quality

- Lower long-term operational costs

- Contribute to environmental sustainability

Conclusion

GMT brick pallets have revolutionized the block machine industry with their unmatched durability, dimensional accuracy, and eco-friendly design. As demonstrated by the successful collaboration with Ms. Emmami in Iran, these pallets are a reliable and cost-effective solution for manufacturers worldwide.

Whether you are producing concrete blocks, pavers, or tiles, GMT brick pallets can help you achieve higher efficiency, better product quality, and significant cost savings. Make the switch today and experience the difference for yourself!