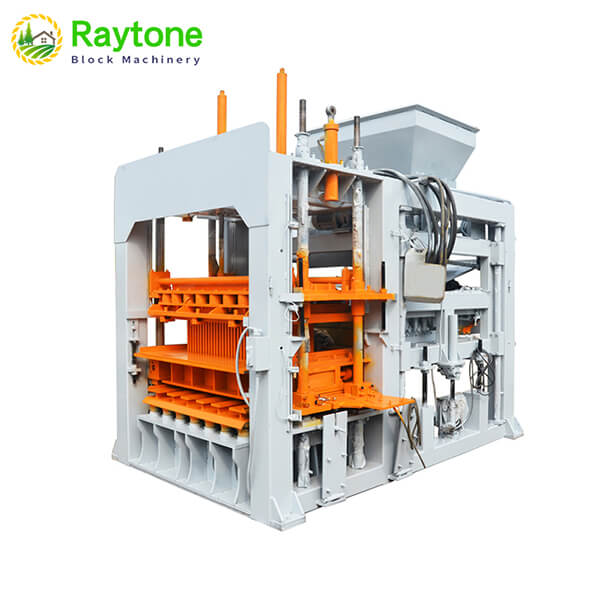

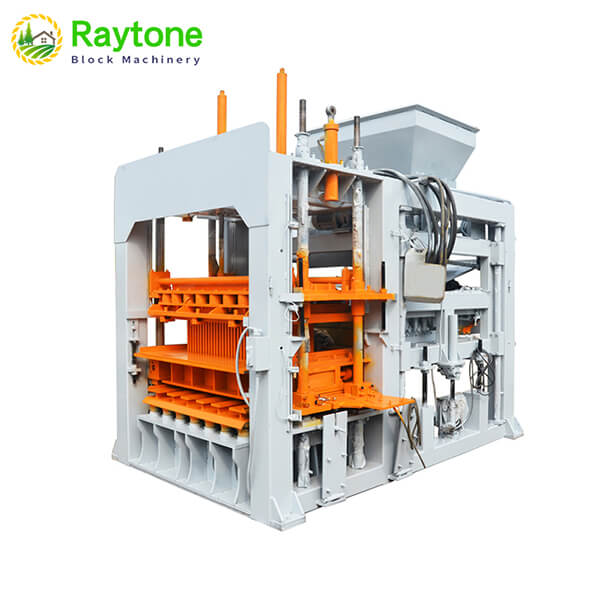

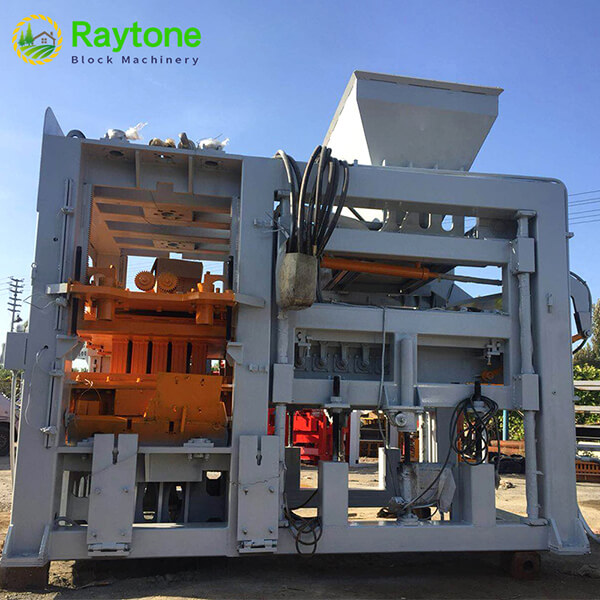

QT8-15 Automatic Hydraulic Concrete Block Making Machine

The QT8-15 is a high-output, fully automated concrete block making machine capable of producing a wide variety of blocks with advanced vibration technology and high-density results.

Introduction Of QT8-15 Automatic Hydraulic Concrete Block Making Machine

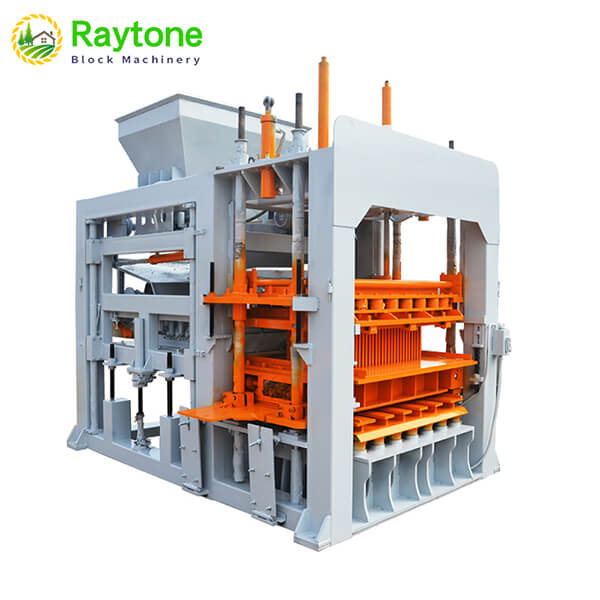

The QT8-15 Automatic Hydraulic Concrete Block Making Machine is a large-scale, high-performance machine designed for the production of various types of blocks, including hollow, solid, colored pavers, curbstones, and more.

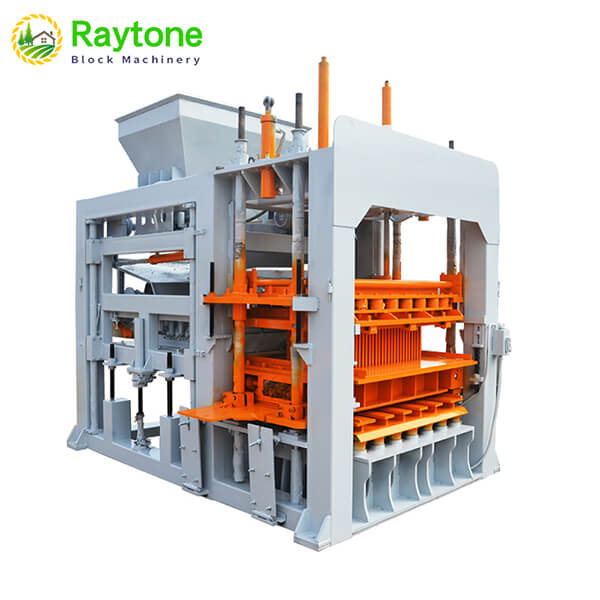

The QT8-15 Automatic Hydraulic Concrete Block Making Machine is equipped with a PLC control panel, with Siemens as an optional brand, and utilizes world-renowned electrical components such as Schneider circuit breakers, Omron sensors, CHNT switches, and Vicruns frequency converters.

The machine’s most notable feature is its double vibration system, which increases block density, accelerates the molding process, and guarantees consistent block strength. The QT8-15 also features a precise material storage and feeding system, which ensures accurate distribution and high-density block production.

The QT8-15 Automatic Hydraulic Concrete Block Making Machine employs a swinging feeder and synchronization vibration technology to optimize material compaction.

The machine’s intelligent control system, combined with fault diagnosis and remote control capabilities, makes it user-friendly and minimizes the need for professional operators.

With a high production capacity of up to 15,360 8-inch hollow blocks per day, the QT8-15 is ideal for large-scale production environments, offering a great balance of productivity, durability, and value for money.

Advantages of the QT8-15 Automatic Hydraulic Concrete Block Making Machine

1. Enhanced Density and Strength:

The QT8-15 block making machine has been refined over time, and now incorporates twice-vibration of moulding from the former one-time-vibration. This upgrade enhances block density, accelerates the shaping process, and ensures more uniform block strength.

2. Accurate Material Feeding:

The advanced storage and material feeding system ensures precise and even distribution of materials, resulting in high-density, high-strength blocks while avoiding material inconsistencies.

3. Low Maintenance and Reliable Operation:

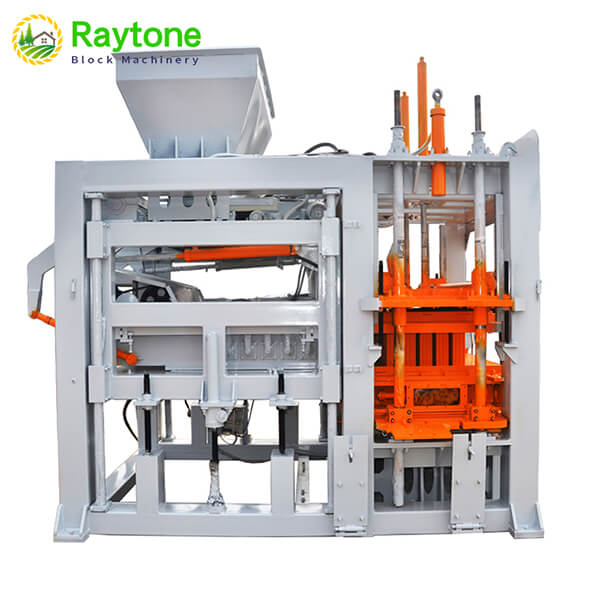

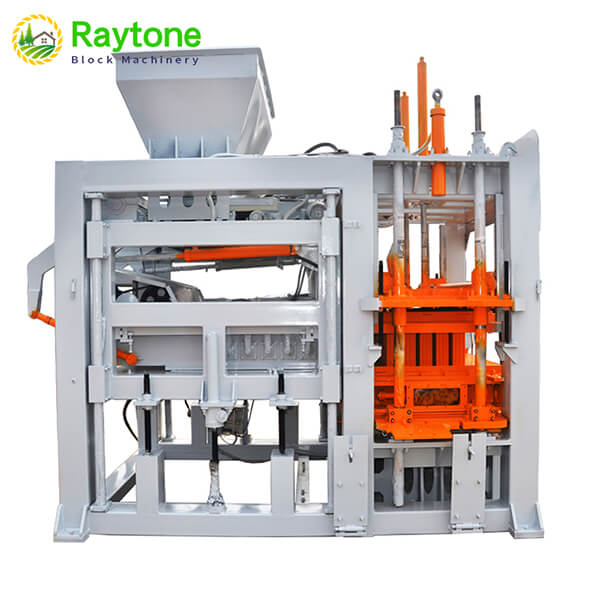

The material feeder system, utilizing German technology with a swinging spline shaft, has a low fault rate, enhancing the machine’s reliability and reducing downtime.

4. User-Friendly Control System:

The PLC control panel with intelligent fault diagnosis and remote control capabilities allows for easy operation, requiring minimal training and enabling efficient production management.

Get Free Quote of QT8-15 Automatic Hydraulic Concrete Block Making Machine

QT8-15 Automatic Brick Making Machine Overview

The QT8-15 fully automatic brick making machine is designed for medium to high volume production. It combines reliability with high performance to meet the demands of modern construction projects.

- Production Capacity: 8-inch hollow blocks: Up to 15,360 pieces per day (8 hour shift).

- Price Range: From $40,000 to $80,000 USD, depending on configuration and production line setup.

1. Advanced Vibration Technology:

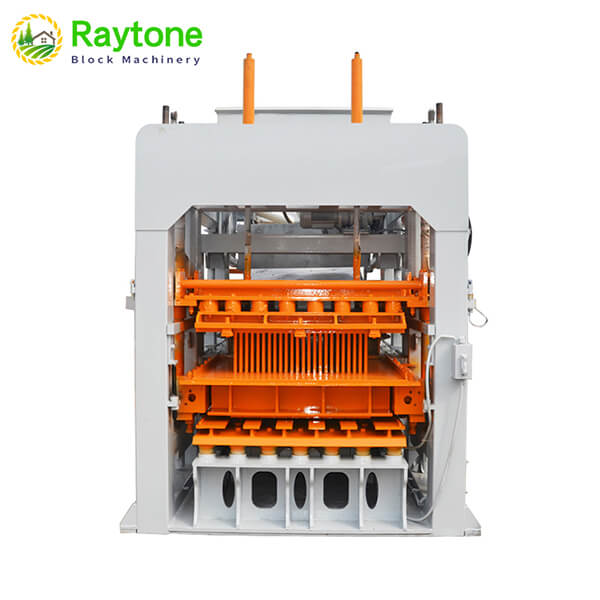

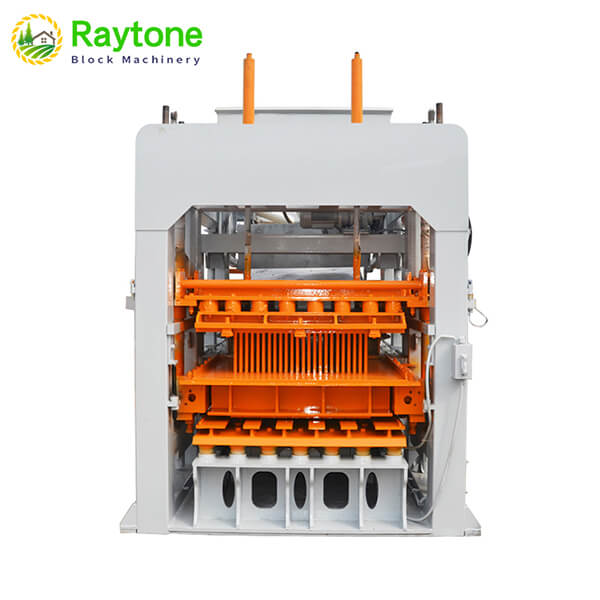

The QT8-15 Automatic Hydraulic Concrete Block Making Machine utilizes a synchronized double vibration system with four vibration motors, ensuring even and strong vibration across the entire mold, which improves molding speed and reduces wear on the mold.

2. Efficient Material Feeding System:

The system uses four vibration motors for even, powerful vibrations, ensuring quick molding and reducing mold wear. The extended vibration shaft and cast vibration box provide stable, low-noise operation while preventing oil leakage.

3. Proportional Valve Control:

The machine features a YUKEN hydraulic proportional valve system, providing precise control over vibration frequency and material feeding to ensure optimal compaction and shaping for various block types.

4. Durable and Stable Construction:

The vibration shaft and vibration box are lengthened and designed to operate with reduced noise and enhanced stability, contributing to smoother operation and extending the life of the equipment.

QT8-15 Automatic Hydraulic Concrete Block Making Machine Line Basic Requirements for Production Start

The following information for the QT8-15 Automatic Hydraulic Concrete Block Making Machine is provided for theoretical reference only.

Actual production data may vary slightly depending on the specific raw materials used.

| Land area | 2500-6500 Square Meters | Water Consumption | 9.6 T/day |

| Workshop area | 200 Square Meters | Electricity Voltage &Frequency | 220V/380V/415V; 50HZ/60HZ |

| Labors Quantity | 6 workers | Power Consumption | 76.8KW*8 Hours=614.4 KWH; |

| Cement Consumption | 25.2 Tons per day | Sand consumption | 100.8 tons per day |

| Crushed stones consumption | 124.8 tons per day |

Detailed Introduction of QT8-15 Automatic Hydraulic Concrete Block Making Machine Line

| Number | Item | Function |

| 1 | Batching Machine | Batch raw material automatically |

| 2 | JS750 Pan Mixer | Mix raw material including cement, sand, stone |

| 3 | 8m Belt Conveyor | Carry Mixed material from mixer to Block machine |

| 4 | Host Brick Machine | Produce different sizes of blocks by changing molds |

| 5 | Hydraulic Station | Supply Hydraulic Press |

| 6 | Automatic PLC | Automatic PLC Control for block machine |

| 7 | Automatic Stacker | Stack the finished hollow blocks to several layers |

Paraments Of QT8-15 Automatic Hydraulic Concrete Block Making Machine Host Machine

| Item | Paraments |

| Host brick machine | Shed or workshop area:200 square meters

Factory area:2500 square meters Labor quantity:4 Moulding area: 936x880mm Vibration Frequency: 4600 times/M Machine power:50.2kw Vibration force:80-100 KN Moulding Period:12-20 S Diesel Generator Capacity: 100KVA Machine size: 8300*1860*3000mm Machine weight: 8500kg |

QT8-15 Automatic Hydraulic Concrete Block Making Machine Daily Production Capacity

| QT8-15 Automatic Hydraulic Concrete Block Making Machine | ||||||

| Size(LxWxH) (mm) | Forming Period (S) | Photo | Pcs/ Mould | Pcs/Hour | Pcs/ 8 hours | |

| (1) | hollow block 400*250*200 | 15 |  |

6 | 1440 | 11520 |

| (2) | hollow block 400*200*200 | 15 |  |

8 | 1920 | 15360 |

| (3) | hollow block 400*150*200 | 15 |  |

10 | 2400 | 19200 |

| (4) | hollow block 400*100*200 | 15 |  |

16 | 3840 | 30720 |

| (5) | Solid Brick 240*50*115 | 15 |  |

42 | 10080 | 80640 |

| (6) | Porous Brick 240*115*90 | 15 |  |

21 | 5040 | 40320 |

| (7) | Curbstone 500*200*300 | 15 |  |

2 | 480 | 3840 |

| (8) | “I” shape paver brick 200*163*60 | 20 |  |

16 | 2880 | 23040 |

| (9) | “S” Shape Paver Brick 225*112.5*60 | 20 |  |

21 | 3780 | 30240 |

| (10) | Holland Brick 200*100*60 | 20 |  |

28 | 5040 | 40320 |

| (11) | Square Paver 250*250*60 | 20 |  |

9 | 1620 | 12960 |

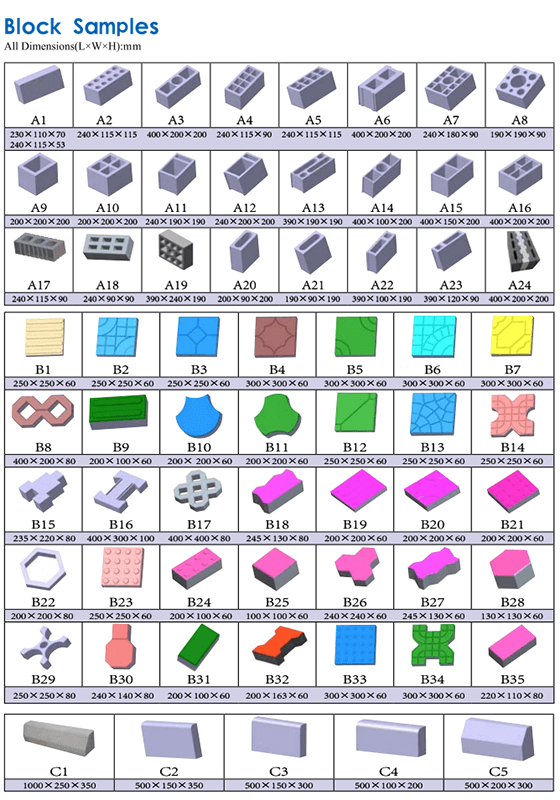

QT8-15 Automatic Hydraulic Concrete Block Making Machine - Sample Brick Showcase

Clients can review the brick models shown in the photo below and choose the one that best suits their needs to confirm the corresponding brick molds for production.

We can also manufacture custom brick molds based on the dimensions and photos of your specific bricks.

Packing List for the QT8-15 Automatic Hydraulic Concrete Block Making Machine Full Production Line

(1) What is the packing method?

The machine can be packed in different ways: nude packing, plastic wrapping, or in a plywood box, depending on customer requirements.

(2) Which motor and electrical brand do we use for the machine?

We use Siemens brand motors and electrical components, or alternatively, well-known Chinese brands for reliable performance.

(3) What type of steel is used for the machine and molds?

The machine is made of Q235B steel, and the molds are made from Mn steel, which is known for its durability and long-lasting performance.

(4) Will you send engineers to install the machine?

Yes, we have a dedicated technician service team. They will provide installation and commissioning services as per customer requirements.

(5) Are spare parts included with the machine?

Yes, we will provide spare parts along with the machine. These parts are designed to last for over two years, ensuring uninterrupted production.

(6) Do you offer free technical support during production?

Yes, we provide 24-hour online technical support to assist with any issues or questions during production.

(7) What is the warranty period for the machine?

The machine comes with a 1-year warranty, excluding wear-and-tear parts. If any quality issues arise within this period, we will cover the shipping costs for replacements.

Working Videos

(1) What is the packing method?

The machine can be packed in different ways: nude packing, plastic wrapping, or in a plywood box, depending on customer requirements.

(2) Which motor and electrical brand do we use for the machine?

We use Siemens brand motors and electrical components, or alternatively, well-known Chinese brands for reliable performance.

(3) What type of steel is used for the machine and molds?

The machine is made of Q235B steel, and the molds are made from Mn steel, which is known for its durability and long-lasting performance.

(4) Will you send engineers to install the machine?

Yes, we have a dedicated technician service team. They will provide installation and commissioning services as per customer requirements.

(5) Are spare parts included with the machine?

Yes, we will provide spare parts along with the machine. These parts are designed to last for over two years, ensuring uninterrupted production.

(6) Do you offer free technical support during production?

Yes, we provide 24-hour online technical support to assist with any issues or questions during production.

(7) What is the warranty period for the machine?

The machine comes with a 1-year warranty, excluding wear-and-tear parts. If any quality issues arise within this period, we will cover the shipping costs for replacements.

Related Products

Related News

The QT8-15 Automatic Brick Making Machine has established itself as a versatile and indispensable piece of equipment in the modern construction […]

Understanding the power requirements of industrial equipment is crucial for efficient operations and planning. The QT8-15 Automatic Brick Making Machine, […]

The QT8-15 Automatic Brick Making Machine employs an advanced hydraulic molding system that combines pressure and vibration to create high-quality concrete […]

Understanding the energy consumption of industrial equipment is crucial for businesses looking to optimize their operations and reduce costs. The […]

The QT8-15 Automatic Brick Making Machine represents a significant advancement in concrete block manufacturing technology, combining high productivity with exceptional versatility. […]

The QT8-15 Automatic Brick Making Machine represents a significant advancement in concrete block manufacturing technology. This sophisticated equipment combines high production […]