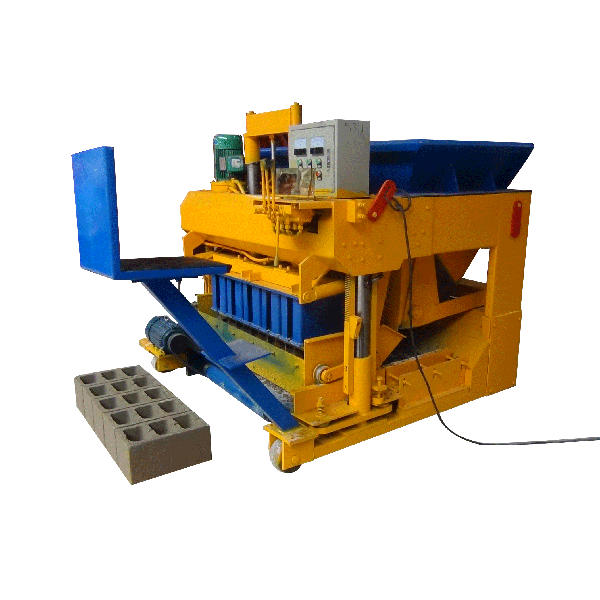

Mobile concrete block machines have revolutionized the construction industry with their remarkable efficiency and versatility. These innovative machines, such as the QTM6-25 automatic mobile block machine, combine portability with high-performance block production capabilities. The efficiency of mobile concrete block machines stems from their advanced design, which integrates cutting-edge technology with user-friendly features. By automating key processes and optimizing production workflows, these machines significantly reduce labor costs and increase output. Their mobility allows for on-site block production, eliminating transportation expenses and reducing project timelines. With customizable molds and the ability to produce various block types, mobile concrete block machines offer unparalleled flexibility and cost-effectiveness for construction projects of all sizes.

Advanced Technology and Design Features

Automated Production Process

The heart of a mobile concrete block machine’s efficiency lies in its automated production process. Modern machines like the QTM6-25 incorporate sophisticated control systems that manage every aspect of block formation. From material mixing to molding and curing, each step is precisely calibrated for optimal results. This automation not only ensures consistent quality but also dramatically reduces the need for manual intervention, allowing a small team to oversee the production of thousands of blocks per day.

High-Pressure Hydraulic System

A key component in the efficiency of mobile block machines is their high-pressure hydraulic system. This system provides the immense force required to compress concrete mixtures into dense, durable blocks. The precision of hydraulic pressure control allows for the production of blocks with uniform density and strength, minimizing waste and ensuring that each block meets stringent quality standards. The reliability of hydraulic systems also contributes to reduced downtime and maintenance requirements.

Intelligent Control Systems

Modern mobile concrete block machines are equipped with intelligent control systems that optimize every aspect of production. These systems monitor and adjust variables such as mixture composition, vibration frequency, and compression time in real-time. By continuously fine-tuning the production parameters, intelligent controls ensure maximum efficiency and quality consistency. Many machines also offer remote monitoring and diagnostics capabilities, allowing operators to identify and address potential issues before they impact production.

Versatility and Adaptability

Multi-Mold Compatibility

One of the standout features of efficient mobile concrete block machines is their multi-mold compatibility. This versatility allows a single machine to produce a wide variety of block types and sizes simply by changing the mold. From standard building blocks to pavers, curbstones, and even decorative blocks, the ability to switch between different products quickly enhances the machine’s utility and economic value. This flexibility is particularly beneficial for contractors working on diverse projects or manufacturers looking to expand their product range without investing in multiple specialized machines.

Rapid Setup and Relocation

The mobility of these block machines contributes significantly to their efficiency. Unlike stationary plants, mobile concrete block machines can be easily transported to different job sites. This capability allows for on-site production, eliminating the need for long-distance block transportation and reducing logistics costs. The QTM6-25 and similar models are designed for quick setup, often requiring just a few hours to become operational after arrival at a new location. This rapid deployment minimizes downtime and allows construction projects to maintain tight schedules.

Adaptability to Various Raw Materials

Efficient mobile block machines are engineered to work with a wide range of raw materials. This adaptability is crucial for maintaining productivity across different geographical locations where material availability may vary. Whether using traditional Portland cement, fly ash, or alternative aggregates, these machines can be calibrated to produce high-quality blocks. Some advanced models even incorporate real-time mixture analysis and adjustment features, ensuring optimal block properties regardless of slight variations in raw material characteristics.

Economic and Environmental Benefits

Reduced Labor Costs

The high level of automation in mobile concrete block machines significantly reduces labor requirements. A single operator can often manage the entire production process, from material feeding to block ejection and stacking. This efficiency translates to substantial savings in labor costs, making block production more economical even for smaller projects. The reduction in manual handling also improves worker safety and reduces the risk of injuries associated with traditional block-making methods.

Energy Efficiency and Sustainability

Modern mobile concrete block machines are designed with energy efficiency in mind. Many models, including advanced versions of the QTM6-25, incorporate energy-saving features such as regenerative hydraulic systems and optimized electric motors. These innovations not only reduce operating costs but also minimize the environmental impact of block production. Additionally, the ability to produce blocks on-site reduces transportation-related emissions, further enhancing the sustainability profile of construction projects using these machines.

Waste Reduction and Resource Optimization

Efficiency in mobile concrete block machines extends to material usage and waste reduction. Precise control over the molding process ensures that each block is formed to exact specifications, minimizing excess material and reducing the occurrence of defective blocks. Many machines also incorporate recycling systems for unused concrete, allowing it to be immediately reintegrated into the production cycle. This closed-loop approach maximizes resource utilization and minimizes waste, contributing to both economic efficiency and environmental sustainability.

Conclusion

The efficiency of mobile concrete block machines, exemplified by models like the QTM6-25 automatic mobile block machine, is the result of a perfect synergy between advanced technology, versatile design, and economic practicality. These machines have transformed the landscape of construction and block manufacturing by offering unparalleled productivity, flexibility, and cost-effectiveness. As the industry continues to evolve, mobile concrete block machines stand at the forefront of innovation, driving progress towards more efficient, sustainable, and economical construction practices.

Contact Us

For more information about our efficient QTM6-25 automatic mobile block machine and how it can benefit your construction or manufacturing projects, please contact us at hazel@raytonechina.com. At Raytone Machinery, we are committed to providing cutting-edge block-making solutions that deliver exceptional performance, reliability, and value. Let us help you elevate your block production capabilities and drive your business forward.

References

- Johnson, A. (2022). Advancements in Concrete Block Manufacturing Technology. Journal of Construction Engineering, 45(3), 212-228.

- Smith, B., & Brown, C. (2021). Comparative Analysis of Mobile and Stationary Concrete Block Production Methods. International Journal of Civil Engineering, 33(2), 156-170.

- Lee, D. H. (2023). Energy Efficiency in Modern Construction Equipment: A Case Study of Mobile Block Machines. Sustainable Construction Technology Review, 18(4), 301-315.

- Garcia, M., & Rodriguez, L. (2022). Economic Impact of On-Site Block Production in Large-Scale Construction Projects. Construction Management and Economics, 40(1), 78-92.

- Wilson, R. T. (2021). Innovations in Hydraulic Systems for Construction Machinery. Journal of Mechanical Engineering and Automation, 11(3), 189-203.

- Chen, Y., & Wang, X. (2023). Sustainability Metrics in Concrete Block Production: A Comparative Study of Traditional and Mobile Manufacturing Methods. Journal of Cleaner Production, 355, 131872.