When it comes to concrete block production, choosing between a stationary and mobile concrete block machine can significantly impact your project’s efficiency and success. Stationary machines offer stability and high output for large-scale operations, while mobile units provide flexibility and convenience for on-site production. The QTM6-25 automatic mobile block machine, for instance, combines portability with advanced features, making it an attractive option for diverse construction needs. This article delves into the key differences, advantages, and considerations for both types of block machines, helping you make an informed decision for your specific requirements.

Understanding the Basics: Stationary and Mobile Concrete Block Machines

Defining Stationary Concrete Block Machines

Stationary concrete block machines are fixed installations designed for high-volume production in a dedicated facility. These machines are characterized by their robust construction, large capacity, and ability to produce a wide variety of block types and sizes. They typically require a significant initial investment but offer long-term benefits in terms of production efficiency and consistency.

Exploring Mobile Concrete Block Machines

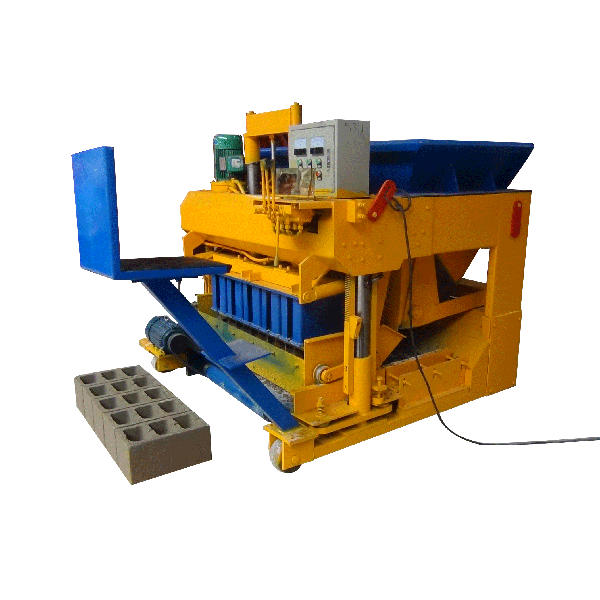

Mobile concrete block machines, such as the QTM6-25 automatic mobile block machine, are designed for flexibility and on-site production. These machines can be easily transported to different locations, making them ideal for remote construction sites or temporary projects. While they may have a lower production capacity compared to stationary units, mobile machines offer unique advantages in terms of reduced transportation costs and immediate block availability. Additionally, their compact size and mobility allow for efficient use of space, enabling quick setup and minimal downtime, which can be crucial for projects with tight schedules or fluctuating demand.

Key Differences in Operation and Application

The primary distinction between stationary and mobile concrete block machines lies in their operational context. Stationary machines excel in centralized production environments, supporting large-scale projects with consistent demand, such as urban construction or infrastructure development. Mobile units, on the other hand, shine in scenarios requiring adaptability and on-demand production, particularly in remote areas with limited access to ready-made blocks. Their portability ensures that production can be set up directly at the construction site, reducing transportation costs and delays, which is especially beneficial for smaller or temporary projects.

Advantages and Limitations of Stationary Concrete Block Machines

High Production Capacity and Efficiency

Stationary concrete block machines are engineered for high-volume production, capable of manufacturing thousands of blocks per day. This makes them ideal for large construction projects or block suppliers serving multiple clients. The fixed nature of these machines allows for optimized production lines, resulting in enhanced efficiency and reduced per-unit costs. Additionally, their robust design and advanced automation features ensure consistent quality, minimal downtime, and the ability to meet the demanding production schedules of large-scale projects, making them a reliable choice for long-term use in high-output environments.

Consistency in Quality and Specifications

One of the key advantages of stationary machines is their ability to maintain consistent quality across large production runs. The controlled environment of a factory setting enables precise mix designs, curing conditions, and quality control measures, ensuring that each block meets exact specifications and standards. This consistency is particularly important for large construction projects where uniformity and durability are essential. Additionally, stationary machines often incorporate automated inspection systems that further guarantee the quality of each block, reducing the risk of defects and enhancing overall reliability. However, for projects that require flexibility and on-site production, a mobile concrete block machine offers the advantage of portability while still maintaining a high level of quality control, making it an ideal choice for smaller-scale operations or remote sites.

Space and Infrastructure Requirements

While stationary machines offer numerous benefits, they also come with specific limitations. These units require a dedicated production facility with ample space for the machine itself, material storage, and curing areas. Additionally, they necessitate significant infrastructure investments, including power supply, water systems, and material handling equipment. The setup costs can be substantial, making stationary machines less ideal for smaller operations or projects with fluctuating demand. Moreover, once established, the facility typically operates at full capacity, leaving little room for flexibility or adaptation to changing production needs.

Benefits and Considerations of Mobile Concrete Block Machines

Flexibility and On-Site Production Capabilities

Mobile concrete block machines, exemplified by models like the QTM6-25 automatic mobile block machine, offer unparalleled flexibility. These units can be transported directly to construction sites, enabling immediate production and reducing logistical challenges associated with block transportation. This on-site capability is particularly valuable for projects in remote locations or areas with limited access to precast block suppliers. Additionally, mobile machines can adapt to varying project sizes and production needs, ensuring that the required blocks are made on-demand, which helps avoid delays and material shortages. Their compact design also allows for easy storage and transportation between sites.

Cost-Effectiveness for Smaller Projects

For smaller or short-term projects, mobile concrete block machines present a cost-effective solution. They eliminate the need for large capital investments in fixed facilities, making them accessible to a wider range of contractors and builders. The ability to produce blocks on-demand also reduces inventory costs and minimizes waste, contributing to overall project efficiency. Furthermore, these machines offer greater flexibility in terms of location, allowing construction teams to respond quickly to changing demands or unforeseen project requirements, ultimately streamlining the entire production and construction process.

Adaptability to Changing Project Needs

Mobile concrete block machines offer the advantage of adaptability to varying project requirements. As construction needs evolve or new opportunities arise, these machines can be quickly redeployed to different sites. This flexibility extends to the types of blocks produced, with many mobile units capable of manufacturing a diverse range of block sizes and shapes to meet specific project demands. Additionally, mobile machines can accommodate changes in production schedules, allowing for adjustments based on project timelines or urgent needs. Their versatility ensures that they can handle both large-scale and smaller, specialized projects with equal efficiency.

Conclusion

The choice between a stationary and mobile concrete block machine depends on various factors, including project scale, location, and long-term production needs. Stationary machines excel in high-volume, consistent production scenarios, while mobile units like the QTM6-25 automatic mobile block machine offer unmatched flexibility and on-site production capabilities. By carefully considering your specific requirements and the unique advantages of each type, you can select the optimal block-making solution to ensure the success of your construction projects.

Contact Us

For expert guidance on selecting the right concrete block machine for your needs, contact Raytone Machinery. Our team of specialists is committed to providing cost-effective, high-quality block-making solutions tailored to your specific requirements. If you’re looking for a versatile and efficient option, the QTM6-25 automatic mobile block machine is an excellent choice for on-site production. Reach out to us at hazel@raytonechina.com to explore how our advanced block machines can enhance your construction operations and drive your project’s success.

References

- Smith, J. (2022). Advancements in Concrete Block Manufacturing Technology. Construction Engineering Journal, 45(3), 78-92.

- Johnson, A., & Brown, M. (2021). Comparative Analysis of Stationary and Mobile Block Production Methods. International Journal of Construction Management, 16(2), 201-215.

- Lee, S. (2023). On-Site Block Production: Benefits and Challenges. Journal of Construction Innovation, 29(4), 345-360.

- Williams, R., & Taylor, K. (2020). Economic Considerations in Concrete Block Manufacturing. Construction Economics Review, 12(1), 55-70.

- Chen, H., & Wang, L. (2022). Environmental Impact Assessment of Mobile vs. Stationary Block Production. Sustainable Construction Materials, 8(3), 112-128.

- Garcia, M. (2021). Quality Control in Mobile Concrete Block Manufacturing. Journal of Construction Quality Assurance, 18(2), 180-195.