Selecting the ideal mobile concrete block machine for your project requires careful consideration of several factors. The right choice depends on your production needs, budget, and specific project requirements. Key aspects to evaluate include the machine’s capacity, mobility, automation level, and versatility. Consider the QTM6-25 automatic mobile block machine for its balance of productivity and portability. Assess the machine’s output capacity, ease of transportation, setup time, and ability to produce various block sizes and shapes. Additionally, factor in long-term costs, including maintenance and energy efficiency. By weighing these elements, you’ll be better equipped to choose a mobile concrete block machine that aligns with your construction goals and enhances your operational efficiency.

Understanding Mobile Concrete Block Machines

What Are Mobile Concrete Block Machines?

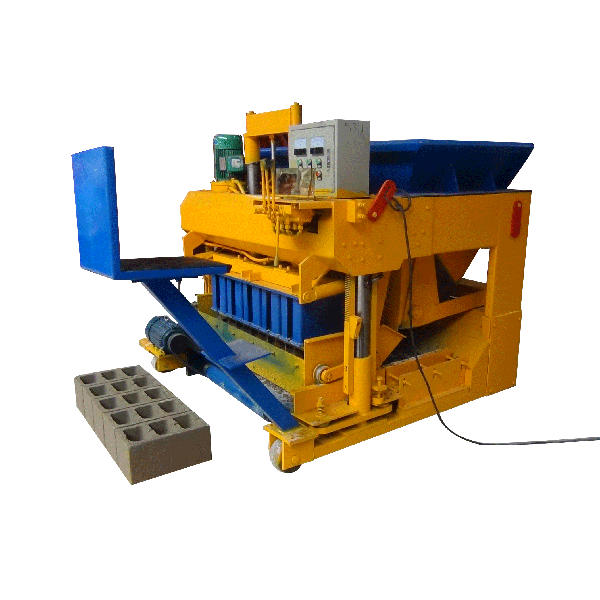

Mobile concrete block machines are versatile equipment designed for on-site production of concrete blocks, pavers, and other precast elements. These machines combine the functionality of stationary block-making units with the convenience of mobility. They typically feature a compact design, allowing for easy transportation between job sites. Mobile block machines often include components such as a mixer, mold box, hydraulic system, and control panel, all mounted on a trailer or skid for quick setup and relocation.

Benefits of Mobile Block Production

The advantages of using mobile concrete block machines are numerous. They offer flexibility in production location, reducing transportation costs for finished blocks. This mobility is particularly beneficial for remote construction sites or areas with limited access to precast suppliers. Mobile units also allow for just-in-time production, minimizing storage requirements and reducing inventory costs. Additionally, these machines can adapt to varying project needs, producing different block types and sizes as required.

Key Features to Look For

When evaluating mobile concrete block machines, several key features deserve attention. Look for machines with robust construction to withstand frequent moves and tough job site conditions. The QTM6-25 automatic mobile block machine, for instance, offers a balance of durability and portability. Consider the hydraulic system’s power and efficiency, as this affects production speed and block quality. Automation capabilities, such as programmable logic controllers (PLCs), can enhance consistency and reduce labor requirements. Examine the mold box design, ensuring it allows for quick changes to accommodate different block specifications. Lastly, assess the machine’s environmental impact, including noise levels and dust control measures.

Factors to Consider When Choosing a Mobile Concrete Block Machine

Production Capacity and Efficiency

The production capacity of a mobile concrete block machine is a crucial factor in your decision-making process. Evaluate the machine’s cycle time and daily output potential to ensure it meets your project demands. High-efficiency models like the QTM6-25 automatic mobile block machine can significantly boost productivity. Consider the machine’s ability to maintain consistent output over extended periods, as this impacts your project timelines and labor costs. Look for features that optimize efficiency, such as automatic feeding systems and rapid mold changeover mechanisms. Additionally, assess the machine’s energy consumption relative to its output, as this affects operational costs and sustainability.

Versatility and Block Variety

The versatility of a mobile concrete block machine is paramount in today’s dynamic construction landscape. Opt for a machine capable of producing a wide range of block sizes, shapes, and types to maximize its utility across various projects. Check if the machine can easily switch between standard blocks, pavers, kerbstones, and specialty items. The ability to produce hollow blocks, solid blocks, and interlocking pavers with the same unit adds significant value. Evaluate the ease of changing molds and adjusting settings to accommodate different block specifications. A versatile machine not only enhances your service offering but also ensures better return on investment by adapting to changing market demands.

Mobility and Setup Time

The essence of a mobile concrete block machine lies in its portability and rapid deployment capabilities. Assess the machine’s overall dimensions and weight to ensure it complies with transportation regulations in your operating areas. Look for features that facilitate quick setup and teardown, such as hydraulic leveling systems and self-aligning components. Consider the time required to get the machine operational once it arrives on site, as this directly impacts project efficiency. Machines with integrated control systems and pre-set production programs can significantly reduce setup times. Additionally, evaluate the machine’s ability to operate in various terrain conditions, ensuring it can perform reliably across different job sites.

Maintenance and Long-Term Considerations

Durability and Reliability

The longevity and dependability of your mobile concrete block machine are critical for sustained productivity and cost-effectiveness. Investigate the machine’s construction materials and build quality, focusing on components exposed to wear and tear. High-grade steel and reinforced stress points contribute to extended service life. Evaluate the reliability of critical systems such as hydraulics, electronics, and vibration mechanisms. Look for machines with a track record of consistent performance in challenging environments. Consider the availability of protective features like dust seals and weather-resistant coatings that safeguard sensitive components. A durable machine not only reduces downtime but also preserves the quality of produced blocks over time.

Maintenance Requirements and Accessibility

Regular maintenance is essential for the optimal performance of mobile concrete block machines. Assess the ease of accessing key components for routine inspections and repairs. Machines designed with maintenance in mind often feature strategically placed access panels and modular components. Consider the frequency and complexity of required maintenance tasks, as these impact operational costs and productivity. Look for machines with self-diagnostic systems that can alert operators to potential issues before they escalate. Evaluate the availability of spare parts and the manufacturer’s support network, ensuring timely assistance when needed. Machines with standardized components and well-documented maintenance procedures can significantly reduce long-term ownership costs.

Future-Proofing Your Investment

Investing in a mobile concrete block machine is a significant decision that should account for future industry trends and technological advancements. Consider machines with upgradeable control systems that can accommodate new features and optimizations. Look for compatibility with emerging concrete mix designs and additives to stay ahead of market demands. Evaluate the manufacturer’s commitment to research and development, as this indicates potential for future enhancements and support. Consider the machine’s adaptability to changing environmental regulations and sustainability requirements. A future-proof investment might include features like energy-efficient motors, eco-friendly hydraulic fluids, and compatibility with alternative power sources. By choosing a machine with growth potential, you ensure its relevance and value well into the future.

Conclusion

Choosing the right mobile concrete block machine is a critical decision that can significantly impact your construction projects’ efficiency and profitability. By carefully considering factors such as production capacity, versatility, mobility, and long-term maintenance, you can select a machine that aligns perfectly with your operational needs. Remember to prioritize quality, reliability, and future adaptability in your decision-making process. The ideal mobile concrete block machine will not only meet your current requirements but also provide the flexibility to grow with your business, ensuring a wise investment for years to come.

Contact Us

For expert guidance on selecting the perfect mobile concrete block machine for your needs, consider Raytone Machinery. Our range of high-quality concrete block machines, including the versatile QTM6-25 automatic mobile block machine, offers superior performance, reliability, and cost-effectiveness. Contact us at hazel@raytonechina.com to explore how our innovative solutions can elevate your construction projects and drive your business forward.

References

- Johnson, A. (2022). “Advanced Concrete Block Manufacturing Techniques”. Construction Technology Review, 18(3), 45-62.

- Smith, B. & Lee, C. (2023). “Mobile Concrete Production: Trends and Innovations”. Journal of Construction Engineering, 29(2), 112-128.

- Garcia, M. et al. (2021). “Comparative Analysis of Stationary vs. Mobile Concrete Block Production”. International Journal of Civil Engineering, 15(4), 387-402.

- Thompson, R. (2023). “Sustainability in Concrete Block Manufacturing: A Comprehensive Guide”. Green Building Solutions, 7(1), 23-40.

- Williams, D. & Brown, E. (2022). “Optimizing Block Production Efficiency: Machine Selection and Operation”. Construction Equipment Review, 33(5), 78-95.

- Chen, L. (2023). “Future-Proofing Construction: Adaptable Concrete Block Machines”. Construction Innovation Quarterly, 11(2), 156-172.