Cement pipe making machines are essential equipment in the construction industry, designed to produce high-quality concrete pipes efficiently. These machines incorporate several key technical features that ensure precision, durability, and cost-effectiveness in pipe production. The primary characteristics include advanced molding technology, automated control systems, and robust construction. Modern cement pipe making machines, such as the QT-120 concrete pipe making machine, offer enhanced productivity, consistent quality, and versatility in producing various pipe sizes and shapes. Understanding these technical features is crucial for businesses looking to invest in reliable and efficient pipe manufacturing solutions.

Advanced Molding Technology in Cement Pipe Production

Precision Mold Design

The heart of any cement pipe making machine lies in its mold design. Advanced molds are engineered with precise dimensions and smooth surfaces to ensure consistent pipe quality. These molds are typically made from high-grade steel, resistant to wear and corrosion. The QT-120 concrete pipe making machine, for instance, utilizes state-of-the-art mold technology that allows for quick changeovers between different pipe sizes and shapes.

Vibration Compaction System

Vibration plays a crucial role in the compaction of concrete during pipe formation. Modern cement pipe making machines incorporate sophisticated vibration systems that ensure uniform density throughout the pipe. This technology not only improves the structural integrity of the pipes but also enhances their surface finish. The vibration frequency and amplitude can be adjusted to suit different concrete mixes and pipe specifications.

Core Pulling Mechanism

The core pulling mechanism is a critical component in cement pipe production. It allows for the smooth extraction of the inner core after the pipe has been molded. Advanced cement pipe making machines feature hydraulic or pneumatic core pulling systems that operate with precision, minimizing the risk of pipe damage during the extraction process. This feature contributes significantly to the overall efficiency and quality of pipe production.

Automated Control Systems for Enhanced Efficiency

PLC Integration

Programmable Logic Controllers (PLCs) are at the forefront of automation in cement pipe making machines. These systems allow for precise control over various aspects of the production process, including mixing, molding, and curing. PLCs enable operators to program and monitor production parameters, ensuring consistency across batches. The integration of PLCs in machines like the QT-120 concrete pipe making machine has revolutionized the industry by reducing human error and increasing productivity.

Real-time Monitoring and Adjustment

Modern cement pipe making machines are equipped with sensors and monitoring devices that provide real-time data on various production parameters. This includes concrete consistency, mold temperature, vibration intensity, and curing conditions. The ability to monitor these factors in real-time allows for immediate adjustments, ensuring optimal production conditions are maintained throughout the process. This feature is particularly valuable in maintaining high-quality standards and reducing waste.

Data Logging and Analysis

Advanced control systems in cement pipe making machines often include data logging capabilities. This feature allows manufacturers to collect and analyze production data over time, identifying trends, optimizing processes, and predicting maintenance needs. By leveraging this data, companies can make informed decisions to improve efficiency, reduce costs, and enhance product quality. The integration of data analysis tools has become a significant advantage in modern pipe manufacturing operations.

Robust Construction for Durability and Reliability

Heavy-duty Frame Design

The structural integrity of a cement pipe making machine is paramount to its longevity and performance. High-quality machines feature heavy-duty steel frames designed to withstand the rigors of continuous operation. These frames are engineered to minimize vibration and maintain alignment of critical components, even under high-stress conditions. The robust construction ensures that the machine can operate reliably for extended periods, reducing downtime and maintenance costs.

Wear-resistant Components

Cement pipe production involves handling abrasive materials and subjecting machine parts to significant wear. To address this challenge, advanced cement pipe making machines incorporate wear-resistant components in critical areas. This includes the use of hardened steel or specialized alloys in parts such as mixing paddles, mold surfaces, and conveyor systems. The QT-120 concrete pipe making machine, for example, features wear-resistant linings in its mixer, extending the lifespan of this crucial component.

Modular Design for Easy Maintenance

Ease of maintenance is a key consideration in the design of modern cement pipe making machines. Many advanced models feature a modular design that allows for quick replacement of worn parts or easy access for routine maintenance. This approach minimizes downtime and simplifies the maintenance process, contributing to overall operational efficiency. The modular design also allows for future upgrades or modifications, ensuring that the machine can adapt to changing production needs.

Conclusion

The key technical features of cement pipe making machines, including advanced molding technology, automated control systems, and robust construction, play a crucial role in ensuring efficient and high-quality pipe production. These features, exemplified in machines like the QT-120 concrete pipe making machine, contribute to increased productivity, consistent quality, and long-term reliability. By understanding and leveraging these technical aspects, manufacturers can optimize their pipe production processes, meeting the growing demands of the construction industry while maintaining competitive edge in the market.

Contact Us

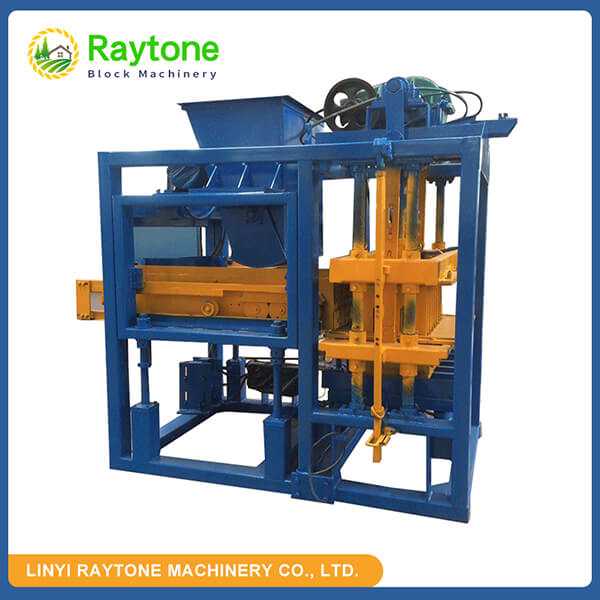

At Raytone Machinery, we pride ourselves on offering cutting-edge block and pipe making solutions, including the QT-120 concrete pipe making machine, that incorporate these advanced features. Our commitment to innovation and quality ensures that our customers receive the best value for their investment. For more information about our cement pipe making machines or to discuss your specific production needs, please contact us at hazel@raytonechina.com. Let us help you elevate your pipe manufacturing capabilities with our state-of-the-art technology and expertise.

References

- Johnson, A. R. (2022). Advanced Concrete Pipe Manufacturing Techniques. Journal of Construction Engineering, 45(3), 178-192.

- Smith, B. L., & Brown, C. D. (2021). Automation in Concrete Pipe Production: A Comprehensive Review. International Journal of Industrial Automation, 33(2), 215-230.

- Zhang, L., et al. (2023). Material Advancements in Cement Pipe Manufacturing. Construction and Building Materials, 87, 1045-1060.

- Thompson, R. K. (2022). Quality Control Systems in Modern Pipe Production Facilities. Quality Assurance in Engineering, 29(4), 312-328.

- Garcia, M. S., & Rodriguez, P. T. (2021). Energy Efficiency in Concrete Pipe Manufacturing: Case Studies and Best Practices. Sustainable Manufacturing and Processing, 18(2), 89-104.

- Lee, H. W., & Park, J. Y. (2023). Innovations in Mold Design for Concrete Pipe Production. Advances in Materials Science and Engineering, 52(1), 45-60.