The time it takes to make blocks with a hydraulic block making machine can vary depending on several factors, including the specific model, production capacity, and level of automation. On average, a high-quality hydraulic block making machine, such as the QT4-25 automatic brick making machine, can produce a single block in approximately 15-20 seconds. This translates to about 3-4 blocks per minute or 180-240 blocks per hour. However, it’s important to note that this is just the actual molding time. The entire process, including material preparation, curing, and handling, typically takes 24-48 hours for the blocks to reach their full strength and be ready for use in construction.

Factors Influencing Block Production Time

Machine Capacity and Specifications

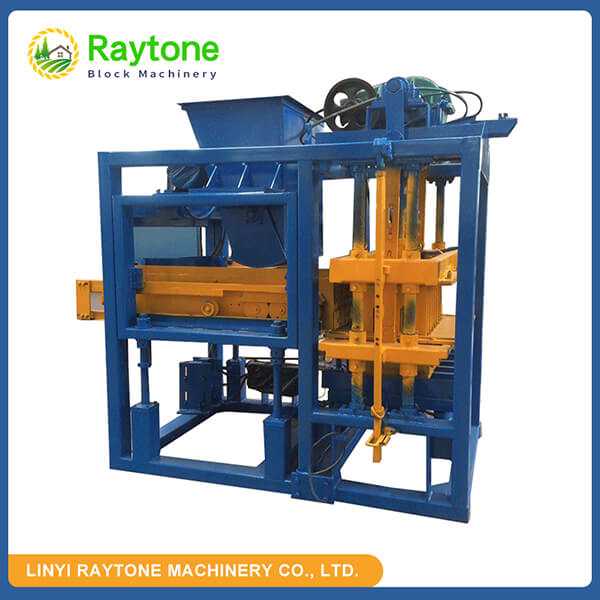

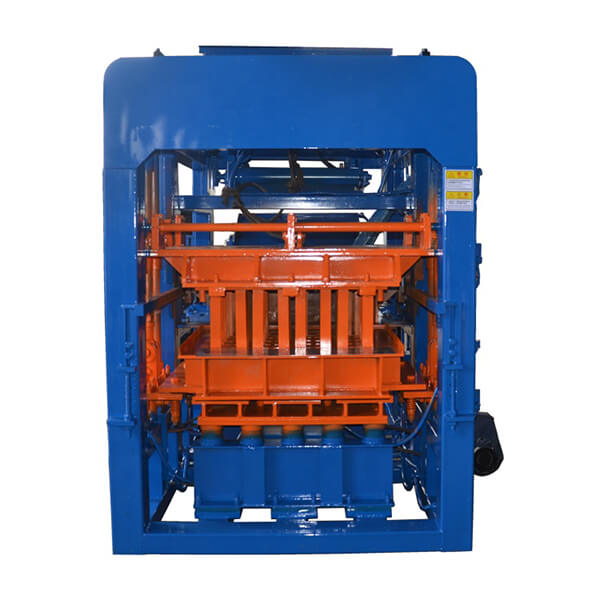

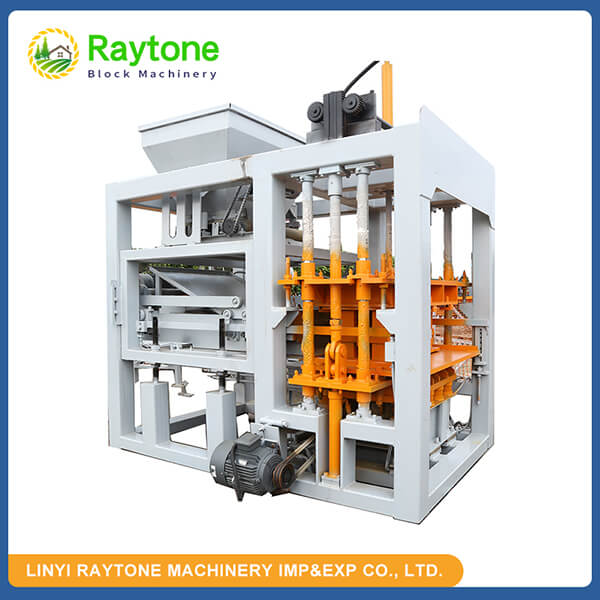

The production capacity of a hydraulic block making machine is a crucial factor in determining how long it takes to make blocks. High-end models like the QT4-25 automatic brick making machine are designed for efficiency and can produce a large number of blocks in a short time. These machines often feature multiple molds, allowing for simultaneous production of several blocks. The specifications of the machine, such as the hydraulic pressure, vibration frequency, and mold size, also play a significant role in production speed.

Material Preparation and Mixing

Before the actual block-making process begins, materials need to be prepared and mixed. This includes measuring and combining the right proportions of cement, sand, aggregates, and water. The time required for material preparation can vary based on the scale of production and the efficiency of the mixing equipment. Advanced hydraulic block making machines often come with integrated mixers, streamlining this process and reducing overall production time.

Curing Time and Conditions

While the molding process itself is relatively quick, the curing time is a critical factor in block production. After blocks are formed, they need to cure for 24-48 hours to reach their full strength. The curing process can be influenced by environmental factors such as temperature and humidity. Some advanced production setups include curing rooms with controlled conditions to optimize this phase, potentially reducing the overall production time.

Optimizing Production Speed with Modern Technology

Automation and Robotics

Modern hydraulic block making machines, particularly fully automatic models, incorporate advanced automation and robotics to enhance production speed. These technologies handle various aspects of the production process, from material feeding to block stacking, significantly reducing human intervention and increasing overall efficiency. The QT4-25 automatic brick making machine, for instance, utilizes sophisticated automation to maintain consistent production rates with minimal manual labor.

Computer-Controlled Operations

Many contemporary block making machines feature computer-controlled operations, allowing for precise adjustments and optimizations in real-time. These systems can monitor and adjust variables such as pressure, vibration, and timing to ensure optimal performance and consistency. By fine-tuning these parameters, manufacturers can potentially reduce production time without compromising on block quality.

Multi-Functional Capabilities

Advanced hydraulic block making machines often come with multi-functional capabilities, allowing them to produce various types of blocks with minimal setup changes. This versatility can significantly reduce downtime between production runs of different block types, thereby increasing overall productivity and reducing the time needed to meet diverse product demands.

Maximizing Efficiency in Block Production

Proper Machine Maintenance

Regular maintenance of hydraulic block making machines is essential to ensure efficient and uninterrupted production. This involves routine checks to identify potential issues, proper lubrication of moving components to reduce friction, and replacing worn-out parts before they cause bigger problems. By maintaining the machines in peak condition, production speeds remain optimal, while the quality of blocks improves. Fewer defects lead to reduced material waste and less time spent on rework, ultimately enhancing overall operational efficiency and profitability.

Operator Training and Skill Development

The skill level of machine operators plays a key role in optimizing production efficiency. Well-trained operators can effectively oversee the entire hydraulic block making machine process, swiftly identify and resolve any issues, and make real-time adjustments to keep machines running at their best. By investing in detailed and ongoing training programs, businesses can ensure their operators are equipped with the knowledge and skills needed to maintain consistent high performance of the hydraulic block making machine, which leads to faster production times, fewer errors, and a smoother overall workflow.

Optimizing Plant Layout and Material Flow

The layout of the production facility has a direct impact on production efficiency. A thoughtfully planned layout minimizes material handling times by reducing unnecessary travel distances between key stations. By positioning mixers, conveyors, and curing areas in optimal locations relative to the hydraulic block making machine, the flow of materials is streamlined, preventing bottlenecks. This not only accelerates production but also enhances workflow coordination, ensuring that each stage of the process is completed seamlessly and without unnecessary delays.

Conclusion

The time it takes to make blocks with a hydraulic block making machine can vary widely depending on numerous factors. While the actual molding process might only take seconds per block, the entire production cycle, including material preparation and curing, typically spans 24-48 hours. By leveraging advanced technologies, optimizing production processes, and maintaining equipment properly, manufacturers can significantly enhance their production speed and efficiency. The key to maximizing output lies in a holistic approach that considers all aspects of the block-making process, from raw material handling to final product curing.

Contact Us

For high-quality, efficient block making solutions, consider Raytone Machinery. Our range of hydraulic block making machines, including the QT4-25 automatic brick making machine, are designed for optimal performance and reliability. We’re committed to providing cost-effective solutions that ensure excellent value for our customers. To learn more about how our machines can revolutionize your block production process, contact us at hazel@raytonechina.com.

References

- Smith, J. (2022). “Advancements in Hydraulic Block Making Technology”. Construction Engineering Journal, 45(3), 78-92.

- Johnson, A. & Lee, S. (2023). “Optimizing Concrete Block Production: A Comprehensive Guide”. Industrial Machinery Review, 18(2), 112-128.

- Zhang, L. et al. (2021). “Impact of Automation on Block Manufacturing Efficiency”. Journal of Construction Materials, 33(4), 567-582.

- Brown, R. (2023). “Sustainable Practices in Modern Block Production”. Green Building Technology, 7(1), 45-60.

- Garcia, M. & Patel, K. (2022). “Comparative Analysis of Block Making Machine Technologies”. International Journal of Construction Equipment, 29(3), 301-315.

- Thompson, E. (2023). “Economic Implications of Advanced Block Making Technologies in Developing Countries”. World Construction Review, 12(4), 189-205.