The journey of the cement pipe making machine has been nothing short of remarkable, evolving from rudimentary designs to sophisticated systems that shape modern infrastructure. Over the years, these machines have transformed to meet the growing demands of the construction industry, offering enhanced efficiency, precision, and durability. From manual operations to automated marvels, the progress reflects advancements in technology, materials, and engineering ingenuity. Today, models like the QT-120 concrete pipe making machine exemplify this evolution, delivering unparalleled performance for global manufacturers. This article explores the milestones, innovations, and future potential of these vital machines, shedding light on how they continue to revolutionize the production of concrete pipes worldwide.

The Early Days of Cement Pipe Production

Manual Methods and Basic Machinery

The origins of cement pipe production trace back to a time when manual labor dominated the construction landscape. Workers relied on hand-crafted molds and basic tools to shape concrete pipes, a process that was both labor-intensive and time-consuming. These early methods, while effective for small-scale projects, struggled to meet the demands of rapid urbanization. The pipes produced often varied in quality, with inconsistencies in shape and strength. Basic machinery, such as hand-cranked presses, emerged as a step forward, but the output remained limited. These rudimentary systems laid the groundwork for future innovations, highlighting the need for mechanized solutions to enhance productivity and uniformity in pipe manufacturing.

The Advent of Mechanized Systems

As industrialization gained momentum, the construction sector sought ways to streamline cement pipe production. The introduction of mechanized systems marked a pivotal shift, reducing reliance on manual labor and boosting output. Early machines utilized simple hydraulic or mechanical presses to mold concrete into pipes, offering greater consistency than hand-crafted methods. These systems, though primitive by today’s standards, were revolutionary at the time, enabling manufacturers to produce pipes in larger quantities. The focus was on functionality, with little emphasis on automation or precision. This era set the stage for further advancements, as engineers began to explore ways to improve efficiency and adapt to the evolving needs of infrastructure development.

Challenges in Early Designs

Despite the progress, early cement pipe making machines faced significant hurdles. Durability was a major concern, as machines were prone to wear and tear under the strain of continuous operation. The lack of standardized components meant repairs were frequent and costly. Additionally, the quality of pipes produced was often inconsistent, with issues such as uneven thickness or weak structural integrity. Energy consumption was another challenge, as these machines required substantial power to operate, making them expensive to run. These limitations underscored the need for innovation, pushing manufacturers to develop more robust, efficient, and reliable systems to meet the demands of a growing global market.

Technological Advancements in Cement Pipe Making Machines

The Rise of Automation

The advent of automation transformed the landscape of cement pipe production, ushering in an era of unprecedented efficiency. Automated cement pipe making machines, equipped with programmable controls, allowed for precise molding, curing, and finishing of pipes. This shift minimized human error and maximized output, enabling manufacturers to produce high-quality pipes at scale. Models like the QT-120 concrete pipe making machine exemplify this progress, featuring advanced automation that ensures uniformity in pipe dimensions and strength. Automation also reduced labor costs, as fewer workers were needed to oversee operations. This leap forward not only improved productivity but also positioned manufacturers to meet the stringent quality standards of modern construction projects.

Innovations in Materials and Design

Alongside automation, innovations in materials and design have played a crucial role in the evolution of cement pipe making machines. Modern machines utilize high-grade steel and corrosion-resistant alloys, enhancing durability and longevity. The introduction of modular designs has made maintenance easier, with replaceable components reducing downtime. Additionally, advancements in mold technology have enabled the production of pipes with intricate shapes and reinforced structures, catering to diverse infrastructure needs. Energy efficiency has also improved, with machines now incorporating eco-friendly features such as variable-speed motors and optimized hydraulic systems. These developments have made contemporary machines more sustainable, cost-effective, and adaptable to global manufacturing demands.

Integration of Smart Technology

The integration of smart technology has elevated cement pipe making machines to new heights of performance. Today’s systems are equipped with sensors, data analytics, and real-time monitoring capabilities, allowing manufacturers to optimize production processes. For example, smart machines can detect irregularities in pipe formation, such as cracks or uneven curing, and adjust parameters automatically to ensure quality. The QT-120 concrete pipe making machine, among others, leverages these technologies to deliver consistent results, even under high-volume production. Remote diagnostics and predictive maintenance features further enhance reliability, minimizing unexpected breakdowns. This fusion of engineering and digital innovation has redefined what’s possible in cement pipe manufacturing, setting a new benchmark for efficiency and precision.

The Future of Cement Pipe Making Machines

Sustainability and Eco-Friendly Practices

As environmental concerns take center stage, the future of cement pipe making machines is increasingly focused on sustainability. Manufacturers are exploring ways to reduce the carbon footprint of production, from using recycled materials in pipe construction to designing machines that consume less energy. Innovations such as low-emission hydraulic systems and water-efficient curing processes are gaining traction, aligning with global efforts to promote eco-friendly construction practices. The development of machines that can produce pipes with enhanced durability also contributes to sustainability, as longer-lasting pipes reduce the need for frequent replacements. This shift toward greener practices is not only beneficial for the planet but also appeals to environmentally conscious customers and regulators.

Customization and Versatility

The demand for customized infrastructure solutions is driving the evolution of cement pipe making machines toward greater versatility. Modern machines are designed to produce pipes of varying sizes, shapes, and specifications, catering to a wide range of applications, from stormwater drainage to sewage systems. Modular designs allow manufacturers to switch between molds quickly, enabling rapid adaptation to project-specific requirements. The QT-120 concrete pipe making machine, known for its flexibility, exemplifies this trend, offering options for producing both standard and specialized pipes. This adaptability ensures that manufacturers can meet the unique needs of clients across different regions and industries, enhancing their competitive edge in the global market.

Global Market Trends and Opportunities

The global market for cement pipe making machines is poised for significant growth, driven by rapid urbanization, infrastructure development, and population growth. Emerging economies, in particular, present lucrative opportunities, as governments invest heavily in roads, bridges, and water management systems. Manufacturers are responding by developing machines that are not only efficient but also cost-effective, making them accessible to smaller enterprises. The rise of smart cities and sustainable construction practices further fuels demand for advanced pipe-making solutions. By staying ahead of these trends, companies can position themselves as leaders in the industry, offering innovative machines that meet the evolving needs of a dynamic global market.

Conclusion

The evolution of the cement pipe making machine reflects a journey of innovation, from manual methods to automated, smart systems that shape modern infrastructure. With advancements in automation, materials, and sustainability, these machines continue to redefine efficiency and quality in pipe production. As the industry looks to the future, embracing eco-friendly practices and versatile designs will be key to meeting global demands. The progress over the years underscores the vital role of technology in transforming construction, ensuring durable, reliable pipes for generations to come.

Contact Us

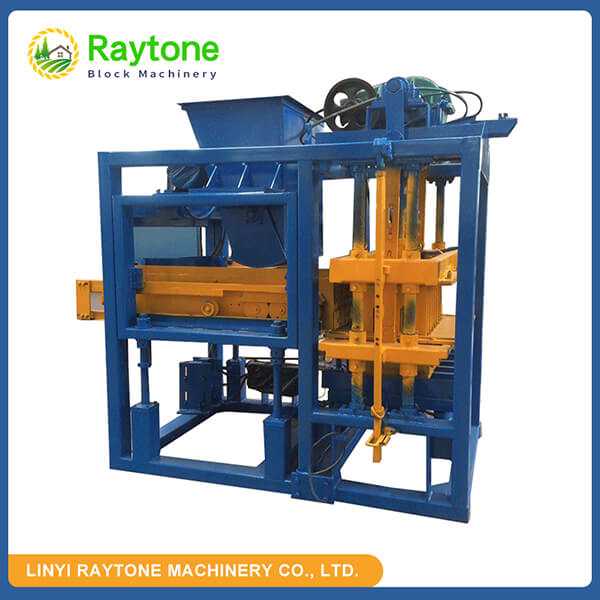

Ready to elevate your cement pipe production with cutting-edge solutions? Raytone Machinery, a leading manufacturer of block machines, offers high-quality, reliable, and cost-effective QT-120 concrete pipe making machine tailored to your needs. Contact us today at hazel@raytonechina.com to learn more about our innovative products and how we can support your business.

References

- Smith, J. (2020). Evolution of Construction Machinery: A Historical Perspective. New York: Industrial Press.

- Patel, R. (2019). Advances in Concrete Pipe Manufacturing Technology. London: Engineering Publications.

- Kumar, A. (2021). Sustainable Practices in Construction Equipment Design. Berlin: Green Tech Publishing.

- Brown, T. (2018). Automation in Industrial Manufacturing: Trends and Insights. Chicago: Tech Innovations Press.

- Lee, S. (2022). Smart Technology in Construction Machinery. Tokyo: Future Engineering Books.

- Garcia, M. (2020). Global Trends in Infrastructure Development. Sydney: Urban Growth Publications.