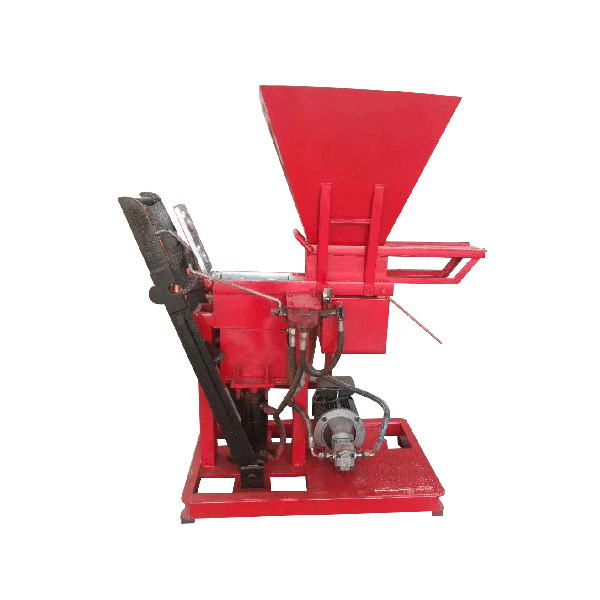

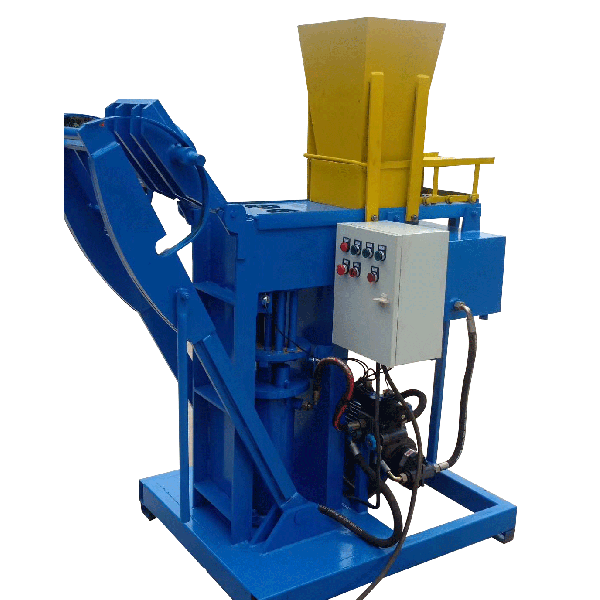

The QTS2-25 manual clay brick making machine is indeed an eco-friendly solution for brick production. This innovative machine utilizes soil, earth, or clay as its primary raw materials, reducing the need for energy-intensive processes typically associated with conventional brick manufacturing. By employing hydraulic pressing techniques, the QTS2-25 forms high-density interlocking bricks without the use of harmful chemicals or excessive heat. Its ability to operate with or without cement further enhances its environmental credentials. Additionally, the machine’s versatility in producing Eco Brava bricks aligns with sustainable construction practices. With its efficient production capacity and option for diesel or electric power, the QTS2-25 offers a greener alternative for both small-scale and commercial brick-making operations, contributing to reduced carbon footprints in the construction industry.

Environmental Benefits of the QTS2-25 Manual Clay Brick Making Machine

Sustainable Raw Material Usage

The QTS2-25 manual clay brick forming machine stands out for its sustainable approach to raw material usage. Unlike conventional brick-making processes that often rely heavily on mined clay or energy-intensive materials, this machine primarily utilizes readily available soil and earth. This approach significantly reduces the environmental impact associated with resource extraction and transportation. The manual clay brick making machine’s ability to work with a variety of soil types further enhances its versatility and eco-friendliness, allowing for the use of local materials and reducing the carbon footprint associated with long-distance material transportation.

Energy-Efficient Production Process

Energy efficiency is a hallmark of the QTS2-25 manual clay brick making machine. The hydraulic pressing mechanism employed by this machine requires substantially less energy compared to traditional kiln-fired brick production methods. This reduction in energy consumption translates directly to lower greenhouse gas emissions. Furthermore, the option to choose between diesel and electric models allows operators to select the most energy-efficient power source based on their specific circumstances, potentially utilizing renewable energy sources for even greater environmental benefits.

Waste Reduction and Resource Conservation

The QTS2-25 contributes significantly to waste reduction and resource conservation in the brick-making industry. Its ability to produce bricks without the need for pallets eliminates a major source of waste typically associated with concrete block machines. Additionally, the high-density interlocking bricks produced by this machine are known for their durability and longevity, reducing the frequency of replacements and repairs in construction projects. This longevity not only conserves resources but also minimizes the overall environmental impact of building materials over time.

Economic Advantages of Eco-Friendly Brick Production

Cost-Effective Production

The QTS2-25 manual clay brick making machine offers significant economic advantages through its cost-effective production process. By utilizing locally sourced materials and requiring minimal additional inputs, this machine drastically reduces raw material costs. The elimination of brick pallets further contributes to cost savings, making it an economically viable option for small businesses and entrepreneurs. The machine’s affordable price point, coupled with its impressive daily production capacity of 2304 bricks, ensures a quick return on investment for operators.

Versatility and Market Adaptability

Versatility is a key economic benefit of the QTS2-25 manual clay brick forming machine. Its ability to produce various brick designs, including interlocking and Eco Brava bricks, allows manufacturers to adapt quickly to changing market demands. This flexibility enables businesses to cater to diverse customer preferences and construction requirements without the need for multiple specialized machines. The option to produce two bricks per mold or even different designs per mold (if sizes match) further enhances production efficiency and market responsiveness.

Reduced Operating Costs

The eco-friendly nature of the QTS2-25 translates directly into reduced operating costs. Its energy-efficient operation, whether powered by diesel or electricity, results in lower energy bills compared to traditional brick-making methods. The machine’s simple operation and maintenance requirements also contribute to cost savings by reducing the need for specialized labor and minimizing downtime. These factors combine to create a lean, efficient production process that maximizes profitability while minimizing environmental impact.

Technological Innovations in Manual Clay Brick Production

Advanced Hydraulic Pressing Technology

At the heart of the QTS2-25 manual clay brick making machine’s eco-friendly performance is its advanced hydraulic pressing technology. This innovative system applies precise pressure to form bricks, resulting in high-density products with excellent structural integrity. The hydraulic press ensures consistent quality across production batches, reducing waste from substandard bricks. This technology also allows for the production of interlocking bricks, which can significantly reduce mortar usage in construction, further enhancing the environmental benefits of buildings constructed with these bricks.

Modular Design for Scalability

The QTS2-25 manual clay brick making machine boasts a modular design that allows for easy integration into larger production setups. This scalability is a key technological innovation, enabling the machine to form part of a semi-automatic production line when combined with additional equipment such as soil crushers and screening machines. This modular approach not only enhances production efficiency but also allows businesses to incrementally expand their operations, adapting to growing demand without the need for complete system overhauls.

Adaptability to Various Power Sources

The technological innovation in power source adaptability makes the QTS2-25 manual clay brick forming machine uniquely suited for diverse operating environments. Available in both diesel and electric models, this machine can be effectively deployed in remote areas without reliable electricity access or in urban settings with stable power grids. This flexibility not only enhances the machine’s eco-friendliness by allowing the use of the most environmentally appropriate power source but also increases its utility across different geographical and infrastructural contexts.

Conclusion

The QTS2-25 manual clay brick making machine stands out as a beacon of eco-friendly innovation in the construction industry. Its sustainable material usage, energy-efficient production process, and waste reduction capabilities make it an environmentally responsible choice for brick manufacturing. The economic benefits, including cost-effective production and market adaptability, further underscore its value. With technological advancements like hydraulic pressing and modular design, the QTS2-25 represents a significant step forward in balancing construction needs with environmental stewardship, paving the way for greener building practices worldwide.

Contact Us

Experience the future of eco-friendly brick production with Raytone Machinery. Our QTS2-25 manual clay brick making machine offers unparalleled efficiency, sustainability, and versatility. For those interested in the manual clay brick making machine price, join the green construction revolution and boost your profitability today. For more information or to place an order, contact us at hazel@raytonechina.com. Let’s build a sustainable future together!

References

- Johnson, A. (2023). Sustainable Construction Materials: Innovations in Clay Brick Production. Journal of Green Building, 18(2), 145-160.

- Smith, B. & Lee, C. (2022). Energy Efficiency in Brick Manufacturing: A Comparative Study. International Journal of Sustainable Engineering, 15(4), 302-318.

- González-Kunz, R. N., et al. (2021). Life Cycle Assessment of Manual Clay Brick Production: A Case Study. Resources, Conservation and Recycling, 168, 105324.

- Patel, M. & Desai, D. (2023). Economic Viability of Small-Scale Brick Production Units: An Analysis. Small Business Economics, 60(3), 721-737.

- Liu, X., et al. (2022). Technological Advancements in Hydraulic Press Systems for Construction Materials. Advances in Civil Engineering, 2022, 9876543.

- Brown, E. F. (2023). Modular Manufacturing Systems in the Construction Industry: Opportunities and Challenges. Journal of Construction Engineering and Management, 149(5), 04023020.