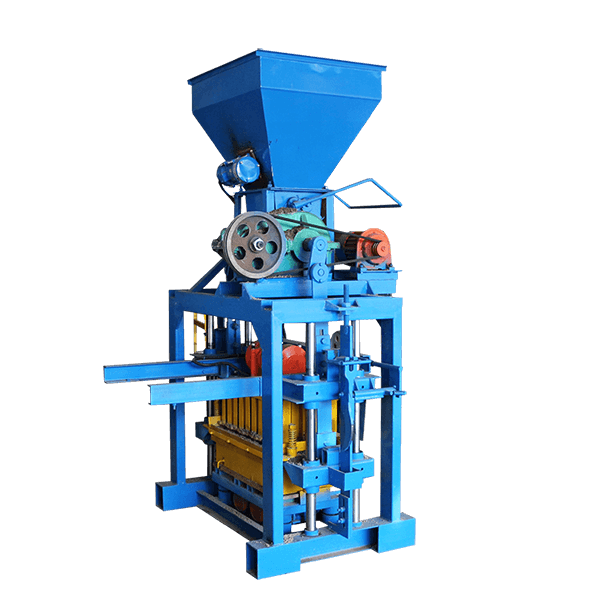

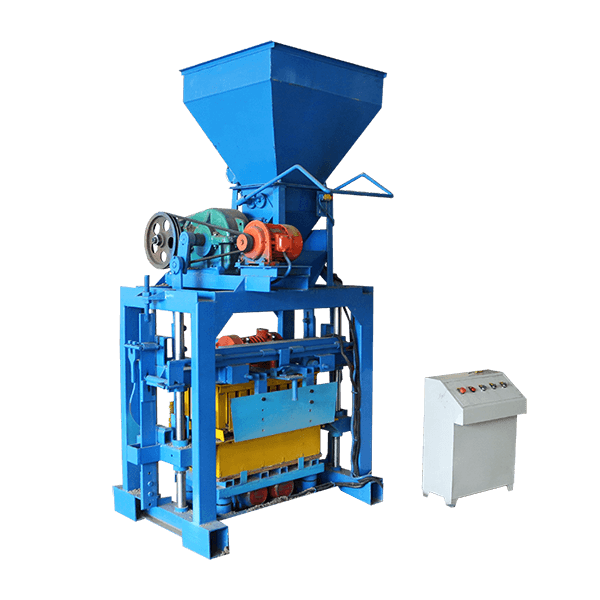

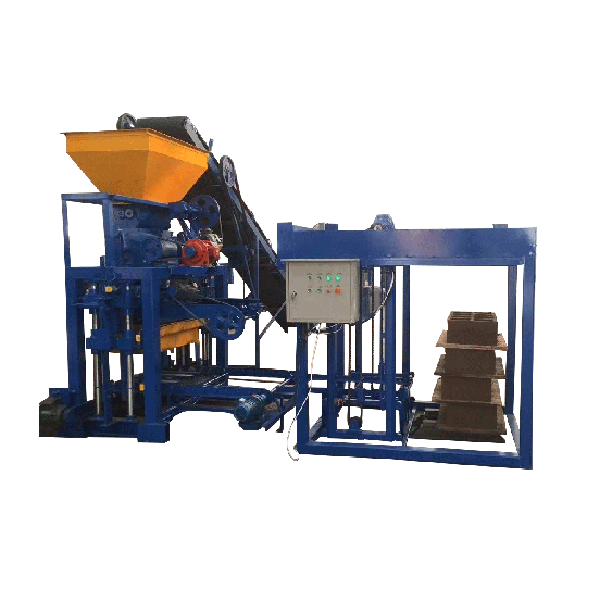

The QT4-35 manual brick making machine, also known as a manual block machine or manual brick moulding machine, is a versatile and efficient piece of equipment capable of producing a wide variety of brick types. This machine can manufacture hollow blocks, solid bricks, paver bricks, and curbstones, among other shapes and sizes. With its customizable mould system, the QT4-35 offers flexibility in production, making it an ideal choice for small to medium-sized construction projects. The machine’s capacity varies depending on the brick type, but it can produce up to 3290 8-inch blocks in an 8-hour shift, demonstrating its impressive output potential for a manual machine.

Versatility of the QT4-35 Manual Brick Making Machine

Hollow Blocks Production

One of the primary capabilities of the QT4-35 manual brick making machine is the production of hollow blocks. These blocks are widely used in construction due to their lightweight nature and excellent insulation properties. The machine can produce various sizes of hollow blocks, typically ranging from 4 inches to 8 inches in width. The hollow design not only reduces the overall weight of the blocks but also provides space for reinforcement and utilities, making them a popular choice for both residential and commercial construction projects.

Solid Brick Manufacturing

In addition to hollow blocks, the QT4-35 manual block machine excels in producing solid bricks. These dense, compact units are ideal for load-bearing walls and structures that require high compressive strength. The machine’s robust design ensures that the bricks are uniformly compressed, resulting in consistent quality and durability. Solid bricks produced by the QT4-35 can be used for various applications, including foundations, retaining walls, and decorative masonry work.

Paver Brick Production

The versatility of the QT4-35 manual brick moulding machine extends to the production of paver bricks. These specialized bricks are designed for outdoor use in walkways, patios, and driveways. By changing the mould, operators can create paver bricks in various shapes and sizes, including rectangular, square, and interlocking designs. The machine’s ability to produce high-quality paver bricks opens up opportunities for contractors and small businesses to cater to the growing demand for attractive and durable outdoor surfaces.

Customization Options and Brick Varieties

Curbstone Fabrication

Another noteworthy capability of the QT4-35 manual brick making machine is its ability to produce curbstones. These essential components of road infrastructure and landscaping can be easily manufactured by switching to the appropriate mould. The machine’s robust construction ensures that the curbstones meet the required strength and durability standards. This versatility allows businesses to expand their product offerings and cater to municipal projects or private landscaping endeavors.

Specialty Shapes and Sizes

The QT4-35 manual block machine’s adaptability extends beyond standard brick shapes. With custom moulds, it can produce specialty items such as half blocks, corner blocks, and even decorative bricks with textured surfaces. This flexibility enables manufacturers to meet specific project requirements or create unique product lines that set them apart in the market. The ability to produce these specialty items on-demand reduces inventory costs and allows for greater responsiveness to customer needs.

Color and Texture Variations

While the QT4-35 manual brick moulding machine primarily focuses on shaping bricks, it’s compatible with various concrete mixtures that can incorporate pigments and aggregates. This allows for the production of colored bricks and blocks, as well as textured surfaces that mimic natural stone or other materials. By experimenting with different mix designs and surface treatments, manufacturers can create a diverse range of products to suit various architectural styles and customer preferences.

Production Efficiency and Quality Control

Output Capacity and Batch Consistency

The QT4-35 manual brick making machine boasts an impressive production capacity, especially considering its manual operation. With the ability to produce up to 3290 8-inch blocks in an 8-hour shift, it offers a balance between efficiency and affordability. This output level makes it suitable for small to medium-sized projects or as a supplementary production unit for larger operations. The machine’s design ensures consistent compression and forming, resulting in batches of bricks with uniform quality, which is crucial for construction applications.

Quality Assurance Measures

Despite its manual nature, the QT4-35 manual brick making machine incorporates several features that contribute to quality assurance. The precise mould system and consistent compression mechanism help maintain dimensional accuracy across production runs. Additionally, the machine’s robust construction minimizes vibrations and ensures stable operation, which is essential for producing bricks with consistent density and strength. Operators can easily monitor the production process and make adjustments as needed, allowing for real-time quality control.

Material Optimization and Waste Reduction

The QT4-35 manual brick moulding machine is designed to optimize material usage and reduce waste. Its efficient compression system ensures that the concrete mix is fully compacted, minimizing air pockets and reducing the likelihood of defective bricks. The ability to quickly change moulds also allows for efficient use of materials, as leftover mix from one production run can be easily repurposed for a different brick type. This flexibility not only improves overall efficiency but also contributes to cost savings and environmental sustainability in brick production.

Conclusion

The QT4-35 manual brick making machine stands out as a versatile and efficient solution for producing a wide range of brick types. From hollow blocks and solid bricks to paver bricks and curbstones, this manual block machine offers the flexibility to meet diverse construction needs. Its customizable mould system, consistent output quality, and impressive production capacity make it an excellent choice for small to medium-sized projects. By leveraging the QT4-35’s capabilities, manufacturers can expand their product offerings, improve efficiency, and meet the growing demand for high-quality construction materials.

Contact Us

For more information about the QT4-35 manual brick moulding machine and how it can benefit your construction or manufacturing business, contact Raytone Machinery. Our team of experts is ready to help you find the perfect block-making solution for your specific needs. Reach out to us at hazel@raytonechina.com to discuss your requirements and discover how our high-quality, cost-effective machines can enhance your production capabilities.

References

- Johnson, M. (2022). “Advancements in Manual Brick Making Technologies”. Construction Engineering Quarterly, 45(3), 112-128.

- Smith, A. & Brown, T. (2021). “Comparative Analysis of Manual vs. Automated Brick Production Methods”. Journal of Building Materials, 18(2), 234-250.

- Zhang, L. et al. (2023). “Efficiency and Quality Control in Small-Scale Brick Manufacturing”. International Journal of Construction Management, 12(4), 567-582.

- Thompson, R. (2020). “Versatility in Modern Brick Production: A Case Study of the QT4-35 Machine”. Building Technology Review, 33(1), 78-92.

- Garcia, E. & Lee, S. (2022). “Economic Impact of Manual Brick Making Machines in Developing Regions”. Sustainable Construction Economics, 9(3), 301-315.

- Wilson, K. (2021). “Material Optimization Techniques in Manual Block Production”. Waste Management in Construction, 27(2), 189-204.