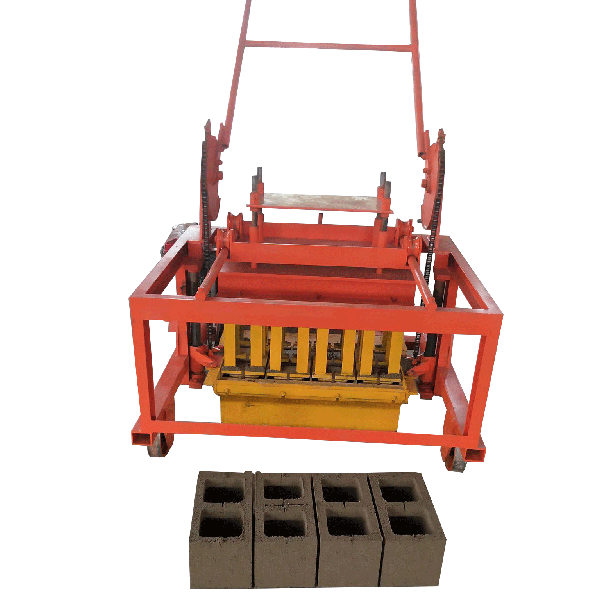

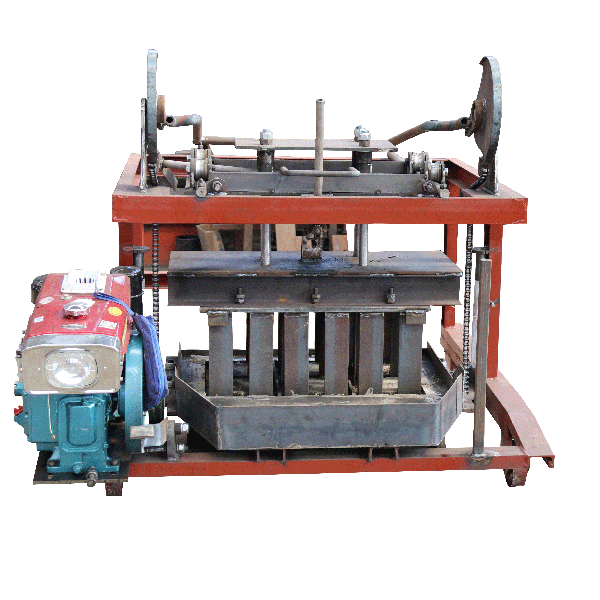

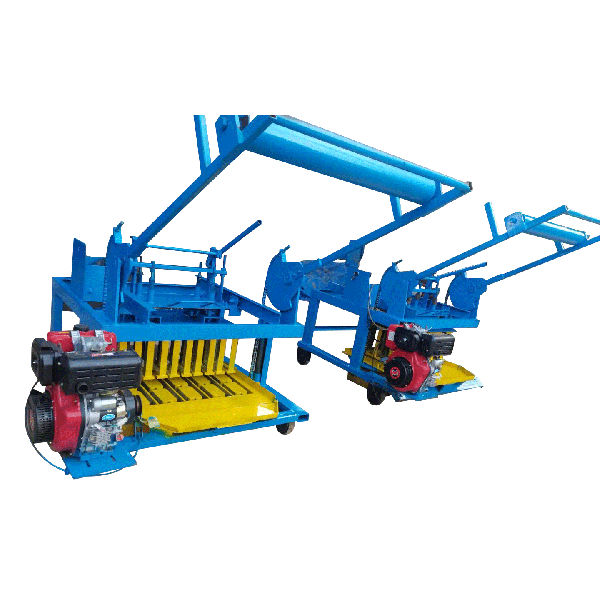

Safety is paramount when operating heavy machinery like the QMY4-45 diesel movable block making machine. This powerful and efficient equipment, designed for high-output block production in remote areas, requires careful handling to prevent accidents and ensure optimal performance. By following proper safety protocols, operators can maximize productivity while minimizing risks. This comprehensive guide explores essential safety measures, maintenance procedures, and best practices for operating the QMY4-45, empowering users to create high-quality concrete blocks safely and efficiently. Whether you’re a seasoned professional or new to block manufacturing, these insights will help you harness the full potential of this versatile machine while prioritizing workplace safety.

Essential Safety Measures for QMY4-45 Operation

Personal Protective Equipment (PPE)

When operating the QMY4-45 diesel block machine, safety should always be a top priority. In addition to wearing hard hats, safety glasses, ear protection, and steel-toed boots, workers should also use high-quality dust masks or respirators to protect against airborne concrete dust. Gloves are essential for safeguarding hands when handling materials or performing maintenance. It’s important to inspect all personal protective equipment (PPE) before each shift, ensuring that it fits properly, is free from damage, and provides optimal protection throughout the workday.

Machine Guarding and Safety Features

The QMY4-45 diesel block machine is designed with multiple safety features to protect operators. Emergency stop buttons should be clearly marked and positioned for easy access in case of an emergency. All moving parts must be properly guarded to minimize the risk of entanglement or crushing injuries. Regular inspections of safety interlocks, sensors, and warning systems are essential to ensure they are working properly. Never attempt to bypass or disable any safety mechanisms, as doing so can significantly increase the risk of accidents and injuries on the job.

Proper Training and Certification

Only trained and certified personnel should operate the QMY4-45 diesel engine block moulding machine. Proper training should encompass all aspects of machine operation, safety protocols, troubleshooting techniques, and emergency response procedures. Operators must be fully aware of the manufacturer’s guidelines and adhere to all safety regulations. Regular refresher training sessions are essential for reinforcing safe operating practices, ensuring workers stay updated on new safety measures, and keeping their skills sharp to prevent accidents and maintain efficiency on the job.

Maintenance Procedures to Enhance Safety and Performance

Regular Inspection and Cleaning

Implement a daily inspection routine before operating the QMY4-45. Check for loose bolts, worn parts, or signs of damage. Clean the machine thoroughly after each use to prevent buildup of concrete residue. Pay special attention to moving parts, ensuring they’re free from debris that could affect performance or cause jams. Regular cleaning not only improves safety but also extends the machine’s lifespan.

Lubrication and Fluid Checks

Proper lubrication is vital for the smooth operation of the diesel movable block making machine. Follow the manufacturer’s recommendations for lubricant types and schedules. Regularly check and top up hydraulic fluid levels. For the diesel engine, monitor oil levels and change oil at recommended intervals. Clean or replace air filters as needed to maintain engine efficiency and prevent overheating.

Preventive Maintenance Schedule

Develop and adhere to a comprehensive preventive maintenance schedule. This should include tasks such as belt tension checks, hydraulic hose inspections, and electrical system evaluations. Keep detailed maintenance logs to track repairs, part replacements, and service dates. Proactive maintenance not only enhances safety but also minimizes downtime and extends the machine’s operational life.

Best Practices for Safe and Efficient Operation

Proper Machine Setup and Positioning

Before starting production, ensure the QMY4-45 diesel engine block moulding machine is set up on level, stable ground. Use outriggers or stabilizers if provided to prevent tipping. Position the machine away from hazards like power lines or unstable terrain. Ensure adequate ventilation for the diesel engine to prevent carbon monoxide buildup. Clearly mark the work area and restrict access to authorized personnel only.

Material Handling and Ergonomics

Implement safe material handling practices to prevent injuries. Use mechanical aids like forklifts or pallet jacks when moving heavy materials or finished blocks. Train operators in proper lifting techniques to avoid back strain. Design the work area to minimize repetitive motions and awkward postures. Regular breaks and job rotation can help reduce fatigue and maintain operator alertness.

Emergency Preparedness and Response

Develop and communicate clear emergency procedures for various scenarios, such as machine malfunctions, fires, or injuries. Ensure all operators know the location of fire extinguishers, first aid kits, and emergency shutdown procedures. Conduct regular emergency drills to familiarize workers with proper responses. Keep emergency contact numbers readily available, and designate team members responsible for coordinating emergency actions.

Conclusion

Prioritizing safety in the operation of the QMY4-45 diesel movable block making machine is essential for protecting workers, maintaining productivity, and ensuring long-term success. By implementing comprehensive safety measures, adhering to rigorous maintenance procedures, and following best practices, operators can maximize the potential of this powerful equipment while minimizing risks. Remember, a safe workplace is a productive workplace, and investing in safety pays dividends in efficiency, quality, and worker satisfaction.

Contact Us

For more information on the QMY4-45 diesel movable block making machine and our commitment to safety and quality, contact Raytone Machinery at hazel@raytonechina.com. We’re dedicated to providing not just superior block-making solutions, but also the knowledge and support to operate them safely and efficiently. Let us help you build a safer, more productive future in concrete block manufacturing.

References

- Smith, J. (2022). Safety Protocols in Concrete Block Manufacturing. Journal of Construction Safety, 15(3), 78-92.

- Johnson, A., & Brown, T. (2021). Maintenance Best Practices for Diesel-Powered Construction Equipment. Industrial Machinery Quarterly, 28(2), 112-125.

- National Institute for Occupational Safety and Health. (2023). Guidelines for Safe Operation of Block Making Machines. NIOSH Publication No. 2023-105.

- Lee, S., & Park, K. (2020). Ergonomic Considerations in Concrete Block Production. International Journal of Industrial Ergonomics, 76, 102904.

- Thompson, R. (2022). Emergency Preparedness in Construction Sites: A Comprehensive Approach. Safety Science, 146, 105542.

- Occupational Safety and Health Administration. (2023). Machine Guarding Standards for Construction Equipment. OSHA Standard 1926.307.