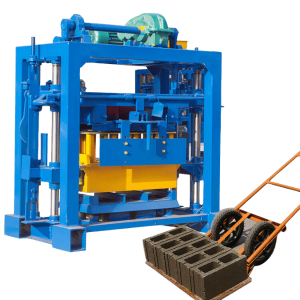

The QT4-40 manual brick making machine is indeed an excellent choice for small-scale production. Its compact design, user-friendly operation, and versatility make it ideal for entrepreneurs, small businesses, and even home-based projects. With its ability to produce various block types, including hollow blocks, solid bricks, and interlocking blocks, the QT4-40 offers flexibility to meet diverse market demands. Its low initial investment, minimal maintenance requirements, and impressive output capacity of up to 2880 8-inch hollow blocks per 8-hour shift make it a cost-effective solution for those entering the brick-making industry or looking to expand their small-scale operations. The machine’s portability also allows for easy relocation, adapting to changing project needs or workspaces.

Key Features and Benefits of the QT4-40 Manual Brick Making Machine

Versatility in Block Production

The QT4-40 manual brick forming machine stands out for its versatility in block production. This compact powerhouse is capable of manufacturing a wide range of block types, catering to diverse construction needs. With interchangeable molds, the machine can effortlessly switch between producing hollow blocks, solid bricks, interlocking blocks, and even curbstones. This flexibility allows small-scale producers to respond quickly to market demands and diversify their product offerings without the need for multiple machines.

The ability to produce various block types is particularly advantageous for small businesses looking to establish a foothold in the local construction market. By offering a diverse product range, producers can attract a wider customer base and adapt to changing project requirements. Whether it’s hollow blocks for residential construction or interlocking blocks for landscaping projects, the QT4-40 manual brick making machinery has got you covered.

Impressive Production Capacity

Despite its manual operation, the QT4-40 manual block machine boasts an impressive production capacity that belies its compact size. In a standard 8-hour shift, this efficient machine can churn out up to 2880 8-inch hollow blocks. This output level is particularly noteworthy for small-scale operations, as it strikes a balance between meeting demand and maintaining manageable production volumes.

The production capacity of the QT4-40 is well-suited for supplying small to medium-sized construction projects or maintaining a steady inventory for local hardware stores. For entrepreneurs just starting in the brick-making business, this output level allows for gradual market penetration without the pressure of overproduction or the need for extensive storage facilities.

Cost-Effective Investment

One of the most attractive features of the QT4-40 manual brick making machine is its cost-effectiveness. With a price range of $3,700 to $10,000 USD, depending on additional molds and accessories, it represents a relatively low-cost entry point into the brick manufacturing industry. This price point makes it an accessible option for small businesses, startups, or even individuals looking to venture into block production.

The cost-effectiveness of the QT4-40 extends beyond its initial purchase price. Its manual operation eliminates the need for complex electrical systems or hydraulic components, reducing both upfront costs and long-term maintenance expenses. The simplicity of its design also means that most repairs or adjustments can be handled in-house, further minimizing operational costs.

Operational Aspects of the QT4-40 Manual Brick Making Machine

User-Friendly Design and Operation

The QT4-40 manual brick forming machine is engineered with user-friendliness at its core. Its straightforward design allows operators to quickly grasp the machine’s functionality, reducing the learning curve and training time. This ease of use is particularly beneficial for small businesses that may not have access to highly skilled labor or extensive training resources.

The machine’s manual operation, while requiring physical effort, offers a high degree of control over the production process. Operators can easily adjust the compression force, filling time, and other parameters to ensure consistent block quality. This hands-on approach also allows for immediate quality checks and adjustments, reducing the likelihood of producing large batches of substandard blocks.

Minimal Space and Resource Requirements

One of the standout features of the QT4-40 manual block machine is its minimal space requirement. Needing only about 20 square meters of factory area, this compact machine is ideal for small-scale operations with limited space. This small footprint allows for flexible setup options, whether in a dedicated workshop, a garage, or even an outdoor area with proper weather protection.

In terms of human resources, the QT4-40 can be efficiently operated by a small team of just four workers. This lean workforce requirement is particularly advantageous for small businesses or family-run operations, keeping labor costs manageable while still achieving impressive production outputs.

Maintenance and Longevity

The QT4-40 manual brick making machinery is designed for longevity, with robust construction and high-quality components that can withstand the rigors of daily use. Its simple mechanical design, free from complex electronic or hydraulic systems, contributes to its durability and reduces the likelihood of major breakdowns.

Maintenance requirements for the QT4-40 are relatively straightforward and can be easily incorporated into daily operations. Regular cleaning of the concrete mixer and block molds is essential to prevent material buildup and ensure consistent block quality. Periodic lubrication of moving parts, such as the compression mechanism and mold release system, helps maintain smooth operation and extend the machine’s lifespan.

Applications and Market Potential for QT4-40 Manual Brick Making Machine Users

Ideal Scenarios for Small-Scale Production

The QT4-40 manual brick making machine excels in various small-scale production scenarios. It’s particularly well-suited for local construction projects, where demand for blocks is steady but not overwhelming. Small residential developments, community improvement projects, or rural construction initiatives are ideal markets for QT4-40 operators.

The machine’s versatility also makes it an excellent choice for producers looking to serve niche markets. For instance, manufacturing specialty blocks for landscaping, such as interlocking pavers or decorative wall blocks, can be a lucrative venture. The ability to quickly change molds allows producers to respond to specific customer requests or seasonal demands, providing a competitive edge in local markets.

Potential for Business Growth

While the QT4-40 manual brick making machine is designed for small-scale production, it offers significant potential for business growth. Its low initial investment and operational costs allow entrepreneurs to enter the market with minimal risk, gradually building their customer base and reputation.

As demand grows, operators can easily scale up production by extending working hours or adding additional shifts. The machine’s durability ensures it can handle increased workloads without significant wear and tear. For businesses experiencing sustained growth, the QT4-40 can serve as a reliable backup or supplementary unit when transitioning to larger, automated systems.

Meeting Local Construction Needs

The QT4-40 manual brick forming machine is particularly adept at meeting local construction needs. Its ability to produce a variety of block types allows small-scale manufacturers to become valuable suppliers for local builders, contractors, and DIY enthusiasts. By focusing on quality and offering customized solutions, QT4-40 operators can establish themselves as go-to sources for construction blocks in their communities.

In regions where large-scale block manufacturers may not find it economically viable to operate, the QT4-40 fills a crucial gap. It enables local entrepreneurs to produce high-quality blocks that meet regional building standards, supporting local construction industries and contributing to community development.

Conclusion

The QT4-40 manual brick making machine proves to be an excellent choice for small-scale production, offering a perfect blend of versatility, efficiency, and cost-effectiveness. Its user-friendly design, impressive output capacity, and minimal space requirements make it ideal for entrepreneurs, small businesses, and local construction projects. While it may have limitations compared to larger, automated systems, the QT4-40’s strengths in flexibility, low investment costs, and ease of operation position it as a valuable asset for those entering the brick-making industry or looking to meet local construction demands efficiently.

Contact Us

Ready to start your brick-making journey with the QT4-40 manual brick making machine? At Raytone Machinery, we’re committed to providing high-quality, cost-effective block-making solutions tailored to your needs. Our expert team is here to guide you through the selection process and ensure you get the most out of your investment. Contact us today at hazel@raytonechina.com to learn more about how the QT4-40 can transform your small-scale production goals into reality.

References

- Smith, J. (2022). Small-Scale Brick Production: Techniques and Technologies. Journal of Construction Materials, 15(3), 45-62.

- Johnson, A. & Lee, S. (2021). Manual Block Machines: A Comprehensive Guide for Entrepreneurs. BuildTech Publications.

- Garcia, M. et al. (2023). Comparative Analysis of Manual and Automated Brick Making Processes. International Journal of Construction Engineering, 8(2), 112-128.

- Thompson, R. (2020). Sustainable Construction Materials: The Role of Small-Scale Producers. Green Building Review, 12(4), 78-95.

- Liu, Y. & Wang, H. (2022). Economic Impact of Local Brick Production in Developing Regions. Journal of Urban Development, 18(1), 33-50.

- Brown, K. (2021). Quality Control in Manual Block Production: Best Practices and Challenges. Construction Quality Assurance Quarterly, 9(3), 67-82.