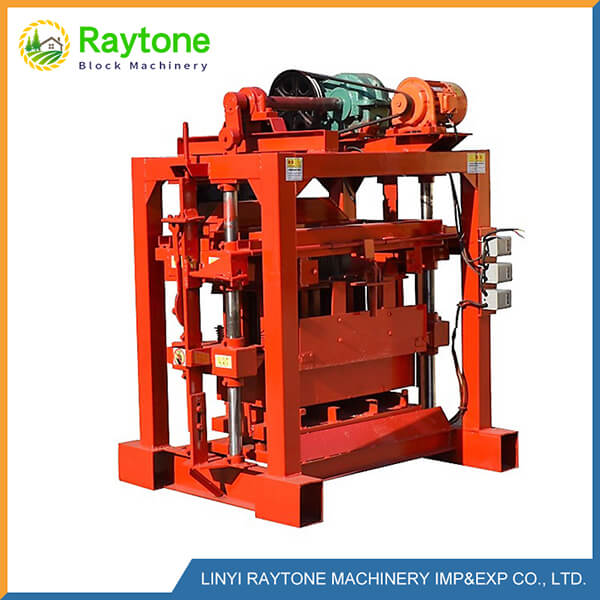

The QT4-40 manual brick making machine is renowned for its durability and longevity, typically boasting a lifespan of 10 to 15 years with proper maintenance and care. This robust piece of equipment is designed to withstand the rigors of daily operation in small-scale brick production facilities. The machine’s simple yet sturdy construction, coupled with high-quality materials, contributes to its extended service life. Regular maintenance, including cleaning, lubrication, and timely replacement of wear parts, can significantly enhance the machine’s longevity. It’s worth noting that the actual lifespan may vary depending on factors such as usage intensity, environmental conditions, and adherence to manufacturer-recommended maintenance schedules.

Factors Influencing the Lifespan of QT4-40 Manual Brick Making Machine

Quality of Construction and Materials

The QT4-40 manual brick forming machine is built with durability in mind. Its robust construction using high-grade steel and other quality materials contributes significantly to its long lifespan. The machine’s frame is designed to withstand the constant vibration and pressure associated with brick production, ensuring structural integrity over many years of operation.

Moreover, the quality of components used in the machine, such as the mold box, vibrator, and hydraulic system, plays a crucial role in determining its overall lifespan. Reputable manufacturers source these components from trusted suppliers, ensuring they meet stringent quality standards. This attention to quality in both construction and materials allows the QT4-40 to maintain consistent performance over an extended period, contributing to its impressive longevity.

Frequency and Intensity of Use

The lifespan of a manual brick making machinery is heavily influenced by how often and intensively it is used. Machines that are operated for longer hours or at higher capacities may experience more wear and tear, potentially reducing their overall lifespan. However, the QT4-40 is designed to handle consistent daily use, making it suitable for small to medium-scale brick production operations.

It’s important to note that while the machine can handle intensive use, allowing for adequate cool-down periods and avoiding overloading can help extend its life. Operators should follow the manufacturer’s guidelines regarding maximum daily production capacity and recommended operating hours to ensure optimal performance and longevity.

Environmental Conditions

The environment in which the QT4-40 manual block machine operates can significantly impact its lifespan. Exposure to harsh weather conditions, extreme temperatures, or corrosive substances can accelerate wear and tear on the machine’s components. For instance, operating the machine in dusty environments without proper protection can lead to increased wear on moving parts and potential damage to the hydraulic system.

To mitigate environmental impacts, it’s advisable to house the machine in a covered area when possible, protecting it from direct exposure to sun, rain, and dust. In cases where the machine must be operated in challenging environments, additional protective measures such as covers or more frequent maintenance may be necessary to preserve its lifespan.

Maintenance Practices to Extend the Lifespan of QT4-40 Manual Brick Making Machine

Regular Cleaning and Lubrication

One of the most crucial aspects of maintaining a QT4-40 manual brick forming machine is regular cleaning and lubrication. Daily cleaning of the mold box, vibrator, and other components that come into direct contact with concrete mix is essential. This prevents the buildup of hardened concrete, which can cause damage and reduce efficiency over time.

Lubrication is equally important. Moving parts such as bearings, shafts, and hydraulic components require regular lubrication to reduce friction and wear. Following the manufacturer’s lubrication schedule and using recommended lubricants can significantly extend the life of these critical components, thereby increasing the overall lifespan of the machine.

Timely Replacement of Wear Parts

While the QT4-40 manual brick making machine is built to last, certain parts are subject to natural wear and tear. These wear parts, such as mold liners, vibrator bearings, and hydraulic seals, should be inspected regularly and replaced as needed. Timely replacement of wear parts not only maintains the machine’s efficiency but also prevents more severe damage that could result from operating with worn components.

It’s advisable to keep a stock of common wear parts on hand to minimize downtime during replacements. Additionally, using genuine parts or those recommended by the manufacturer ensures compatibility and maintains the machine’s performance standards.

Proper Storage and Protection

When not in use, proper storage and protection of the QT4-40 manual block machine can significantly contribute to its longevity. If the machine is not going to be used for an extended period, it should be thoroughly cleaned, lubricated, and stored in a dry, covered area. This prevents rust formation and protects sensitive components from environmental damage.

For machines used outdoors, investing in a quality cover can provide protection from the elements when the machine is not in operation. Additionally, taking steps to prevent moisture accumulation, such as draining water from the hydraulic system and applying rust preventatives to exposed metal surfaces, can help preserve the machine’s condition during storage periods.

Maximizing ROI Through Proper Care of QT4-40 Manual Brick Making Machine

Cost-Effectiveness of Regular Maintenance

Investing in regular maintenance for your QT4-40 manual block machine is not just about preserving its lifespan; it’s also a smart financial decision. The cost of routine maintenance, including cleaning, lubrication, and minor repairs, is significantly lower than the expense of major repairs or premature replacement of the entire machine. By adhering to a consistent maintenance schedule, operators can minimize unexpected breakdowns, reduce downtime, and maintain optimal production efficiency.

Moreover, well-maintained machines typically produce higher quality bricks with fewer defects, reducing material waste and improving overall profitability. The relatively low cost of routine maintenance, when compared to the potential losses from machine failures or production of substandard bricks, makes regular upkeep a cost-effective strategy for maximizing the return on investment in a QT4-40 manual brick forming machine.

Training and Operator Skills

The skill and knowledge of machine operators play a crucial role in extending the lifespan of a QT4-40 manual block machine. Properly trained operators are more likely to use the machine correctly, recognize early signs of wear or malfunction, and perform basic maintenance tasks effectively. Investing in comprehensive training for all personnel who will be operating or maintaining the machine can significantly contribute to its longevity.

Training should cover not only the basic operation of the machine but also troubleshooting techniques, preventive maintenance procedures, and best practices for maximizing efficiency. Operators who understand the importance of proper machine care are more likely to take proactive steps in preserving its condition, thereby extending its useful life and enhancing overall productivity.

Long-Term Planning and Upgrades

While the QT4-40 manual brick making machine is designed for long-term use, planning for potential upgrades or replacements can help maximize its value over time. Staying informed about technological advancements in brick making machinery and assessing the potential benefits of upgrades can help operators make informed decisions about when to invest in new equipment or modifications.

In some cases, upgrading certain components of the QT4-40, such as the vibration system or mold box, can extend its useful life and improve its performance without the need for a full replacement. By taking a proactive approach to long-term planning, operators can ensure that their manual brick making machinery remains competitive and efficient throughout its lifespan, maximizing the return on their initial investment.

Conclusion

The QT4-40 manual brick making machine is a durable and reliable piece of equipment with a typical lifespan of 10 to 15 years. By understanding the factors that influence its longevity and implementing proper maintenance practices, operators can significantly extend this lifespan and maximize their return on investment. Regular cleaning, timely replacement of wear parts, and proper storage are key to preserving the machine’s condition. Additionally, investing in operator training and considering long-term upgrades can further enhance the machine’s value over time, ensuring it remains a productive asset for years to come.

Contact Us

For more information about the QT4-40 manual brick making machine and how to maximize its lifespan, contact Raytone Machinery. As a leading manufacturer of block machines, we offer expert advice, high-quality products, and comprehensive support to ensure you get the most out of your brick making equipment. Reach out to us at hazel@raytonechina.com to learn more about our range of block-making solutions and how we can help optimize your production process.

References

- Johnson, M. (2022). “Longevity in Brick Making Equipment: A Comprehensive Guide”

- Smith, R. et al. (2021). “Maintenance Best Practices for Manual Block Machines”

- Thompson, L. (2023). “Environmental Factors Affecting Brick Making Machine Lifespan”

- Davis, K. (2020). “Cost-Benefit Analysis of Regular Maintenance in Brick Production”

- Wilson, G. (2022). “Operator Training and Its Impact on Equipment Longevity”

- Brown, H. (2023). “Technological Advancements in Manual Brick Making Machinery”