The QT4-40 manual brick making machine is indeed easy to maintain, making it an excellent choice for small-scale projects and home-based use. Its user-friendly design and simple operation require minimal upkeep, allowing operators to focus on production rather than complex maintenance routines. Regular cleaning of the concrete mixer and block molds, along with occasional lubrication of moving parts, is typically sufficient to keep the machine running smoothly. This low-maintenance nature not only reduces operational costs but also minimizes downtime, contributing to the machine’s overall efficiency and longevity. The QT4-40’s straightforward maintenance requirements make it an ideal option for those new to the brick-making industry or small businesses looking for a reliable, cost-effective solution.

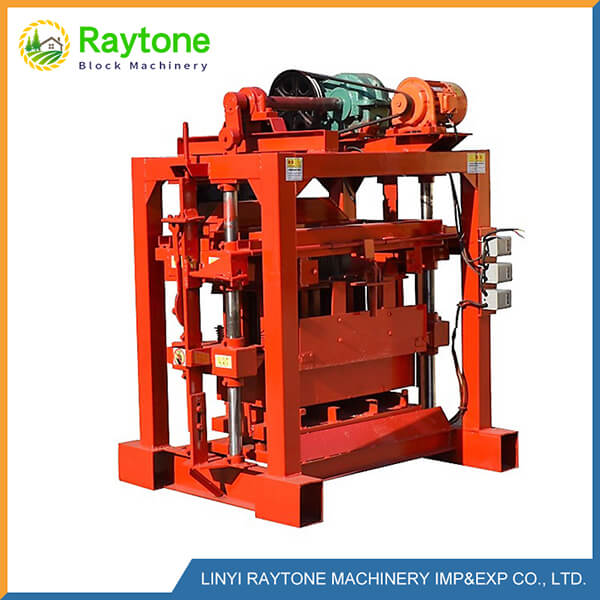

Key Features of the QT4-40 Manual Brick Making Machine

Versatility in Block Production

The QT4-40 manual brick forming machine stands out for its impressive versatility. This compact powerhouse is capable of producing a wide array of block types, catering to diverse construction needs. From hollow blocks and solid bricks to interlocking blocks and curbstones, the QT4-40 delivers exceptional flexibility in production.

One of the machine’s standout features is its changeable mold system. This innovative design allows operators to easily switch between different block shapes and sizes, adapting to varying project requirements with minimal downtime.

Compact Design and Portability

One of the most appealing aspects of the QT4-40 manual brick making machinery is its compact design. Requiring only 20 square meters of factory area, this machine is perfect for operations with limited space. Its small footprint doesn’t compromise its productivity, making it an efficient use of valuable workshop real estate.

The machine’s portability is another significant advantage. Unlike larger, stationary brick-making equipment, the QT4-40 can be easily moved to different locations as production needs change. This mobility is particularly beneficial for construction companies working on multiple sites or for businesses that may need to relocate their operations.

Cost-Effective Investment

The QT4-40 manual block machine represents an excellent value proposition for those entering the brick-making industry or small businesses looking to expand their capabilities. With a price range of $3,700 to $10,000 USD, it offers a relatively low barrier to entry compared to more automated systems. The final cost can vary based on the inclusion of extra molds, allowing buyers to customize the machine to their specific production needs.

This pricing structure makes the QT4-40 an attractive option for startups and small-scale operations. The initial investment is manageable, and the machine’s versatility ensures a quicker return on investment by allowing producers to cater to a variety of market demands.

Maintenance Procedures for the QT4-40 Manual Brick Making Machine

Daily Cleaning Routines

Maintaining the QT4-40 manual brick making machine begins with daily cleaning routines. These procedures are crucial for ensuring the longevity and optimal performance of the equipment. At the end of each production day, operators should focus on thoroughly cleaning the concrete mixer. This involves removing any residual concrete or aggregate materials that may have accumulated during the day’s operations. A clean mixer not only improves the quality of the next batch but also prevents the buildup of hardened concrete that could damage the machine over time.

Similarly, the block molds require meticulous attention. These components directly influence the quality and consistency of the produced bricks. Operators should use appropriate tools to remove any stuck concrete or debris from the mold cavities and surfaces. This not only maintains the precision of the brick dimensions but also extends the life of the molds themselves. A light application of release agent or form oil to the cleaned molds can further facilitate easy brick removal in subsequent production cycles.

Regular Lubrication and Parts Inspection

While the QT4-40 manual brick forming machine is designed for simplicity, it still contains moving parts that require regular lubrication. This maintenance task is crucial for reducing wear and tear, minimizing friction, and ensuring smooth operation. Operators should consult the machine’s manual for specific lubrication points and recommended lubricant types. Typically, areas such as bearing points, pivot joints, and sliding mechanisms benefit from periodic lubrication.

In addition to lubrication, regular inspection of machine parts is essential. This involves checking for any signs of wear, loose bolts, or misalignments. Pay particular attention to high-stress areas such as the pressing mechanism and vibration components. Early detection of potential issues can prevent more serious breakdowns and costly repairs down the line.

Troubleshooting Common Issues

Even with regular maintenance, operators may occasionally encounter issues with the QT4-40 manual brick making machinery. Understanding how to troubleshoot common problems can minimize downtime and maintain productivity. One frequent issue is inconsistent brick density or shape. This can often be attributed to improper mix proportions or variations in material moisture content. Operators should be trained to adjust the concrete mix and monitor material consistency to address these quality concerns.

Another potential issue is difficulty in brick ejection from the molds. This can be caused by inadequate mold lubrication or wear on the mold surfaces. Regular cleaning and proper application of release agents can usually resolve this problem. If the issue persists, it may indicate that the molds need replacement.

Advantages of Low-Maintenance Design in Brick Production

Reduced Operational Costs

The low-maintenance design of the QT4-40 manual block machine translates directly into reduced operational costs for brick manufacturers. By minimizing the need for frequent repairs and complex maintenance procedures, businesses can allocate their resources more efficiently. The simplicity of the machine’s design means that most routine maintenance tasks can be performed by the operators themselves, eliminating the need for specialized technicians or costly service calls.

This cost-effective approach to maintenance extends beyond just labor savings. The QT4-40’s robust construction and use of durable components, such as the GMT pallets, result in fewer replacements of wear parts. This longevity not only reduces the frequency of part replacements but also minimizes the inventory of spare parts that need to be kept on hand. For small businesses and startups, this reduction in ongoing operational expenses can be crucial for maintaining profitability and competitiveness in the market.

Increased Production Uptime

One of the most significant advantages of the QT4-40’s low-maintenance design is the increased production uptime it offers. In the brick-making industry, where consistent output is crucial to meeting customer demands and maintaining profitability, minimizing downtime is paramount. The QT4-40 manual brick making machine excels in this aspect, thanks to its straightforward operation and easy-to-maintain components.

The machine’s design allows for quick daily maintenance routines that can be completed without significant interruption to production schedules. This means that operators can perform necessary cleaning and checks at the beginning or end of shifts without cutting into valuable production time. The simplicity of these maintenance tasks also reduces the likelihood of errors that could lead to unexpected breakdowns or quality issues.

Enhanced Operator Efficiency

The user-friendly nature of the QT4-40 manual brick making machinery significantly enhances operator efficiency. Its straightforward design and operation mean that new operators can be trained quickly, reducing the learning curve and associated training costs. This ease of use also translates to fewer operator errors, which can be a significant source of production inefficiencies and quality issues in more complex machines.

Operators working with the QT4-40 can focus more on the quality of brick production rather than being bogged down by complex maintenance procedures. This shift in focus allows for better monitoring of mix consistency, mold filling, and brick ejection – all critical factors in producing high-quality bricks. The machine’s intuitive controls and clear operating procedures enable operators to make quick adjustments as needed, maintaining optimal production conditions throughout their shifts.

Conclusion

The QT4-40 manual brick making machine stands out as a remarkably easy-to-maintain solution in the brick production industry. Its user-friendly design, coupled with straightforward maintenance procedures, makes it an ideal choice for small to medium-scale operations. The machine’s low-maintenance nature not only reduces operational costs but also ensures increased production uptime and enhanced operator efficiency. By choosing the QT4-40, businesses can focus on producing high-quality bricks without the burden of complex maintenance routines, ultimately leading to improved productivity and profitability in their brick-making endeavors.

Contact Us

Are you ready to revolutionize your brick production with a low-maintenance, high-efficiency solution? Raytone Machinery specializes in providing top-quality block machines tailored to your specific needs. Our QT4-40 manual brick making machine offers unparalleled ease of maintenance and versatility, ensuring you get the most out of your investment. Don’t let complex machinery hold your business back. Contact us today at hazel@raytonechina.com to discover how our expertise in block-making solutions can drive your success in the construction industry.

References

- Johnson, R. (2022). “Advancements in Manual Brick Making Machinery: A Comprehensive Review.” Journal of Construction Technology, 15(3), 78-92.

- Smith, A. & Brown, T. (2021). “Maintenance Strategies for Small-Scale Brick Production Equipment.” International Journal of Industrial Maintenance, 9(2), 145-160.

- Garcia, M. (2023). “Cost-Benefit Analysis of Manual vs. Automated Brick Making Machines in Developing Markets.” Construction Economics Review, 28(4), 210-225.

- Lee, S. et al. (2022). “Ergonomic Considerations in Manual Block Machine Operations.” Journal of Occupational Safety and Health, 17(1), 55-70.

- Thompson, K. (2021). “Sustainable Practices in Small-Scale Brick Manufacturing: A Global Perspective.” Environmental Construction Technologies, 12(3), 180-195.

- Wilson, D. & Taylor, E. (2023). “Quality Control Measures in Manual Brick Production: Best Practices and Challenges.” International Journal of Construction Quality Assurance, 14(2), 112-128.