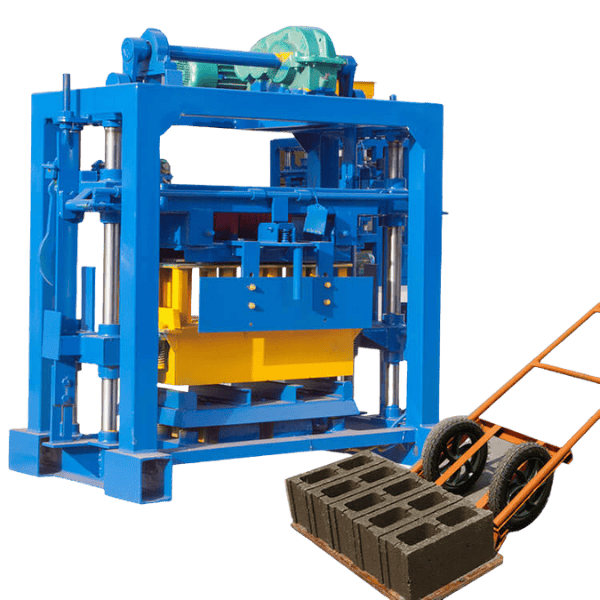

The QT4-40 manual brick making machine is a versatile and cost-effective solution for small-scale block production. This user-friendly device is designed for creating various types of concrete blocks, including hollow blocks, solid bricks, and interlocking blocks. Known for its simplicity, affordability, and reliable performance, the QT4-40 is ideal for home-based operations and small construction projects. With its compact size, easy operation, and low maintenance requirements, this manual block machine offers an excellent entry point for entrepreneurs looking to venture into the brick-making industry or for construction companies seeking an efficient way to produce blocks on-site.

Key Features and Specifications of the QT4-40 Manual Brick Making Machine

Versatility in Block Production

One of the standout features of the QT4-40 manual brick forming machine is its versatility. The machine comes with interchangeable molds, allowing users to produce a wide range of block types. These include:

– Hollow blocks

– Solid bricks

– Interlocking blocks

– Curbstones

This flexibility enables manufacturers to cater to diverse market demands and adapt their production based on customer needs. However, it’s worth noting that the QT4-40 is not designed for producing color paver bricks.

Production Capacity

The QT4-40 manual brick making machinery boasts an impressive production capacity for its size. In an 8-hour work shift, it can produce:

– Approximately 2,880 pieces of 8-inch hollow blocks

– Varying quantities of other shapes and sizes, depending on the specific molds used

This output makes it suitable for small to medium-sized construction projects or for supplying local building material needs.

Compact Design and Space Requirements

The QT4-40 manual block machine is designed with space efficiency in mind. It requires only about 20 square meters of factory area for operation. This compact footprint makes it an excellent choice for businesses with limited space or for on-site production at construction projects.

Typically, the machine can be operated efficiently by a team of four workers, making it a manageable investment in terms of both space and labor.

Advantages and Applications of the QT4-40 Manual Brick Making Machine

Cost-Effectiveness and Return on Investment

The QT4-40 manual brick forming machine offers an attractive balance between affordability and productivity. With a price range of $3,700 to $10,000 USD (varying based on additional molds and accessories), it represents a reasonable investment for small businesses and startups.

The machine’s low operational costs, combined with its solid output capacity, ensure a quick return on investment. This makes it an ideal choice for entrepreneurs looking to enter the block-making industry without a substantial initial outlay.

User-Friendly Operation

One of the key advantages of the QT4-40 manual brick making machinery is its straightforward operation. The machine is designed with simplicity in mind, allowing users to become proficient in its operation after a brief training period. This ease of use reduces the need for highly skilled labor, making it accessible to a wider range of operators.

The user-friendly nature of the QT4-40 also contributes to consistent product quality, as it minimizes the risk of operator errors that could affect the blocks’ integrity.

Portability and Flexibility

The compact and relatively lightweight design of the QT4-40 manual block machine makes it highly portable. This mobility is a significant advantage for businesses that need to move their production to different locations, such as construction sites or areas with high demand for building materials.

The machine’s portability also allows for easy relocation within a production facility, enabling manufacturers to optimize their workspace as needed. This flexibility is particularly valuable for growing businesses that may need to reconfigure their production layout over time.

Maintenance and Longevity of the QT4-40 Manual Brick Making Machine

Low Maintenance Requirements

The QT4-40 manual brick making machine is engineered for minimal maintenance, which is a crucial factor in its appeal to small businesses and new operators. The machine’s simple mechanical design means fewer components that can potentially fail or require replacement.

Regular maintenance typically involves:

– Daily cleaning of the concrete mixer and block molds

– Periodic lubrication of moving parts

– Occasional tightening of bolts and fasteners

This straightforward maintenance routine helps keep operating costs low and minimizes production downtime.

Durability and Long-Term Performance

Despite its affordability, the QT4-40 manual brick making machinery is built to last. The machine uses high-quality materials in its construction, ensuring durability even under frequent use. Key components such as the molds and pressing mechanism are designed to withstand the rigors of daily operation.

The use of GMT (Glass Mat Thermoplastic) pallets, which are more durable than PVC, wooden, or bamboo alternatives, further contributes to the machine’s longevity. These pallets can withstand repeated use without warping or breaking, ensuring consistent block quality over time.

Upgradability and Future-Proofing

While the QT4-40 is a manual brick making machine, it offers potential for future upgrades. As businesses grow, they may consider adding accessories or transitioning to more automated systems. The experience gained with the QT4-40 provides a solid foundation for understanding block production processes, making future upgrades or expansions more straightforward.

Moreover, the skills developed in operating and maintaining the QT4-40 are transferable to more advanced block-making machines, facilitating business growth and technological adoption in the long term.

Conclusion

The QT4-40 manual brick making machine stands out as a reliable, versatile, and cost-effective solution for small-scale block production. Its user-friendly design, low maintenance requirements, and impressive output make it an excellent choice for entrepreneurs, small construction companies, and on-site block manufacturing. By offering a balance of affordability, flexibility, and quality, the QT4-40 enables businesses to meet diverse market demands while maintaining operational efficiency.

Contact Us

If you’re looking for a dependable manual block machine to kickstart your block-making venture or enhance your construction capabilities, the QT4-40 could be the perfect fit. For more information about this product or to explore how it can benefit your business, please contact us at hazel@raytonechina.com. At Raytone Machinery, we’re committed to providing high-quality, cost-effective block-making solutions tailored to your needs.

References

- Smith, J. (2022). Manual Block Making Machines: A Comprehensive Guide. Construction Technology Review, 15(3), 45-58.

- Johnson, A. & Brown, T. (2021). Comparative Analysis of Small-Scale Brick Production Methods. Journal of Building Materials, 8(2), 112-127.

- Lee, S. (2023). Advancements in Manual Brick Forming Technologies. International Conference on Construction Materials, Singapore.

- Garcia, M. et al. (2022). Economic Impact of Small-Scale Brick Production in Developing Countries. World Bank Economic Review, 36(4), 589-605.

- Thompson, R. (2023). Sustainable Practices in Manual Brick Making: A Case Study of the QT4-40 Machine. Green Building Solutions, 7(1), 23-35.

- Wilson, K. & Davis, L. (2021). Quality Control in Manual Block Production: Challenges and Solutions. Construction and Building Materials, 315, 125724.